Membrane bioreactor device and sewage treatment method for slowing down membrane fouling

A technology of membrane bioreactor and membrane pollution, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problems of high energy consumption for aeration and cleaning, membrane surface pollution, etc. Achieve the effects of reducing aeration energy consumption, restoring flux, and slowing down membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

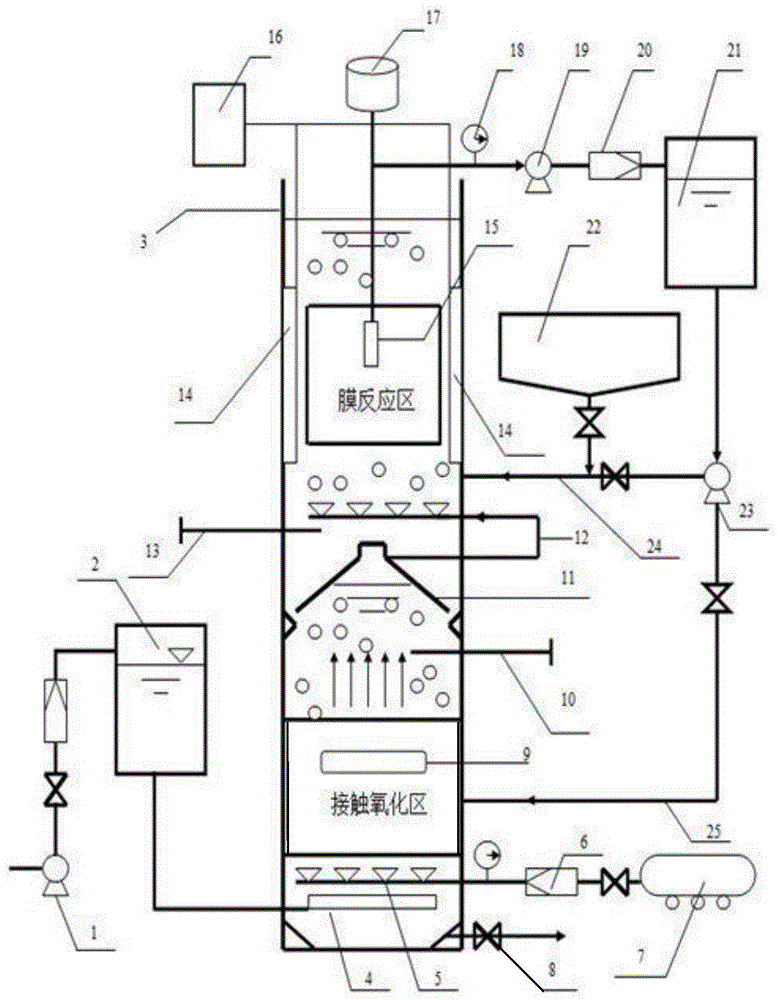

[0035] Specific Embodiment 1: The membrane bioreactor device for slowing membrane fouling of this embodiment includes: sewage lifting pump 1, regulating tank 2, membrane bioreactor 3, perforated water distributor 4, aerator 5, aerator Air gas flow meter 6, aeration fan 7, vent / sludge valve 8, filler 9, closed gate valve 10, three-phase separator 11, air guide pipe 12, closed gate valve 2 13, ultrasonic vibration box 14, membrane module 15, Ultrasonic generator 16, rotating motor 17, pressure gauge 18, suction water pump 19, abortion water flow meter 20, production water tank 21, chemical cleaning agent storage tank 22, backwash water pump 23, backwash water pipeline 1 24, backwash Water pipeline two 25 and a plurality of connecting pipelines and valves; the membrane bioreactor 3 is a hollow container, in the membrane bioreactor 3, the lower part is provided with a perforated water distributor 4, the middle part is provided with a three-phase separator 11, and the upper part is ...

specific Embodiment approach 2

[0039] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the perforated water distributor 4 adopts a porous water distribution method, and a general water distribution pipe is arranged along the bottom of the membrane bioreactor, and water distribution horizontal pipes are arranged at intervals. Open holes at equal intervals on the pipe, the diameter of the water distribution pipe is 50-100cm, the center of the water distribution pipe is 20-25cm from the bottom, and the hole diameter is 15-25mm.

[0040] The aerator 5 adopts a fixed plate microporous aerator with a diameter of 200 mm, an average pore diameter of 100-200 μm, a porosity of 40-50%, an oxygen utilization rate of 20-25%, and a service area of 0.3-0.75 m 2 / indivual. Others are the same as the first embodiment.

specific Embodiment approach 3

[0041] Embodiment 3: This embodiment differs from Embodiments 1 to 2 in that: the bottom of the membrane bioreactor 3 is an inverted truncated cone structure, and the sludge residence time is controlled by the vent / sludge valve 8 for 5-30 days. Others are the same as the specific embodiment 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com