Halobenzene functionalized and modified carbon nano tube and preparation method thereof

A technology of carbon nanotubes and nanotubes, which is applied in the field of surface modification of nanomaterials, can solve the problems of large specific surface area, easy agglomeration, and difficult dispersion of carbon nanotubes, and achieve the effect of improving dispersion and interfacial compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

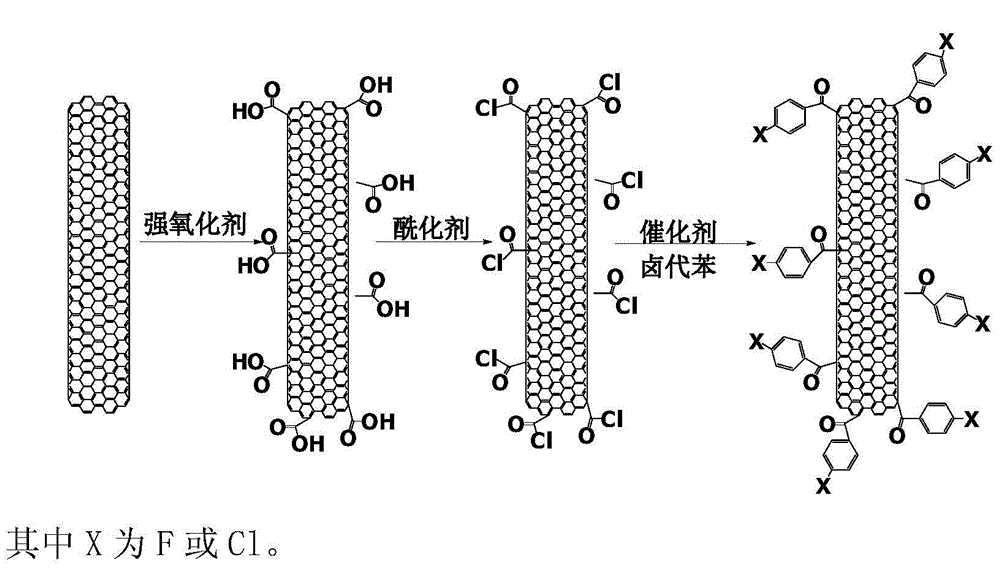

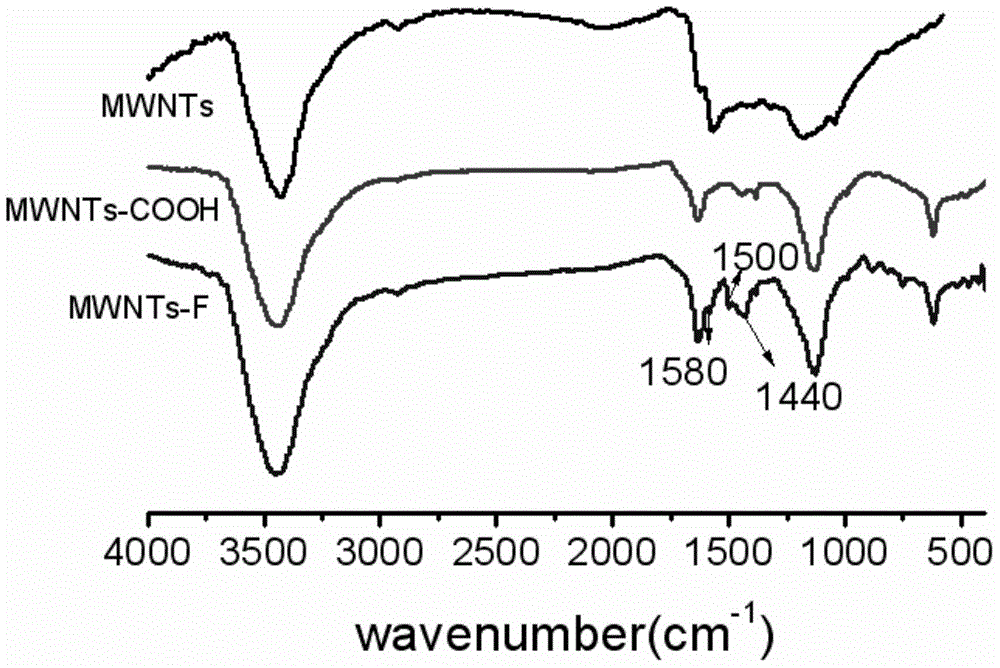

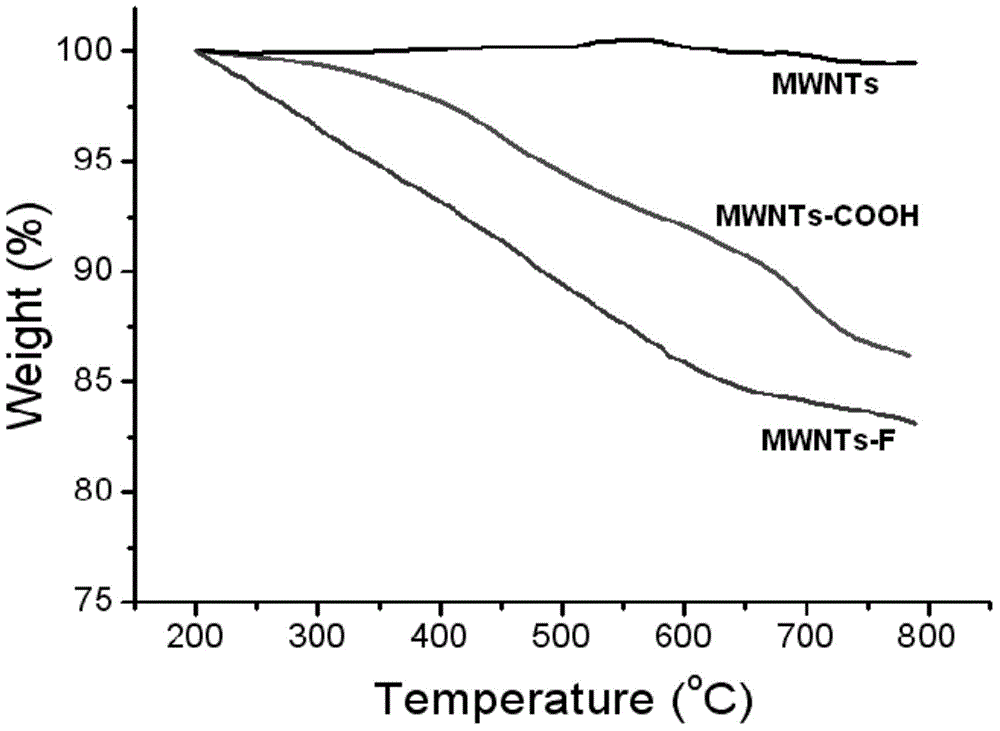

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of oxidized multi-walled carbon nanotubes:

[0029] Add 30 parts of multi-walled carbon nanotubes and 320 parts of concentrated sulfuric acid into a reactor with a stirrer and a thermometer, and react at a temperature of 90°C for 2 hours; slowly pour the reaction solution into 1000 parts of deionized water, and vacuum filter And washed with deionized water several times until the filtrate was neutral. The obtained oxidized multi-walled carbon nanotubes were dried in a vacuum oven at 120° C. for 24 hours to obtain dried oxidized multi-walled carbon nanotubes.

[0030] (2) Preparation of acylated multi-walled carbon nanotubes:

[0031] 30 parts of dry oxidized multi-walled carbon nanotubes, 100 parts of thionyl chloride, 4 parts of pyridine, and 160 parts of anhydrous nitromethane were added to a reactor with a stirrer, a thermometer and a condenser tube, at a temperature of 80 ℃ for 2.5 hours in the dark; vacuum filtration and repeated washing with anhy...

Embodiment 2

[0035] (1) Preparation of oxidized single-walled carbon nanotubes:

[0036] Add 30 parts of single-walled carbon nanotubes and 160 parts of concentrated nitric acid into a reactor with a stirrer and a thermometer, and react at a temperature of 50°C for 12 hours; slowly pour the reaction solution into 400 parts of deionized water, and vacuum filter And washed with deionized water several times until the filtrate was neutral. The obtained oxidized single-walled carbon nanotubes were dried in a vacuum oven at 120° C. for 24 hours to obtain dry oxidized single-walled carbon nanotubes.

[0037] (2) Preparation of acylated single-walled carbon nanotubes:

[0038] 30 parts of dry oxidized single-walled carbon nanotubes, 20 parts of phosphorus pentachloride, 1 part of triethylamine, and 40 parts of anhydrous methylene chloride are added to a reactor with a stirrer, a thermometer and a condensing tube. The reaction was carried out at 30° C. and protected from light for 24 hours; vacu...

Embodiment 3

[0042] (1) Preparation of oxidized single-walled carbon nanotubes:

[0043] Add 30 parts of single-walled carbon nanotubes, 90 parts of concentrated sulfuric acid, and 30 parts of concentrated nitric acid into a reactor with a stirrer and a thermometer, and react at a temperature of 60°C for 5 hours; slowly pour the reaction solution into 300 parts of deionized water , vacuum filtered and washed with deionized water several times until the filtrate was neutral. The obtained oxidized single-walled carbon nanotubes were dried in a vacuum oven at 120° C. for 24 hours to obtain dry oxidized single-walled carbon nanotubes.

[0044] (2) Preparation of acylated single-walled carbon nanotubes:

[0045] Add 30 parts of dry oxidized single-walled carbon nanotubes, 70 parts of phosphorus trichloride, 2.5 parts of 4-dimethylaminopyridine, and 100 parts of anhydrous chloroform into a reactor with a stirrer, a thermometer and a condenser tube reaction at a temperature of 50° C. in the dar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com