Method of removing sulfur and aromatic hydrocarbon from base oil regenerated from waste lubricating oil

A technology for regenerating base oils and waste lubricating oils, applied in lubricating compositions, the petroleum industry, and treating hydrocarbon oils, etc., can solve problems such as difficulty in setting up permits for safe operation, high investment costs, and poor results, without causing Effects of secondary pollution, improvement of operation safety, and reduction of chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

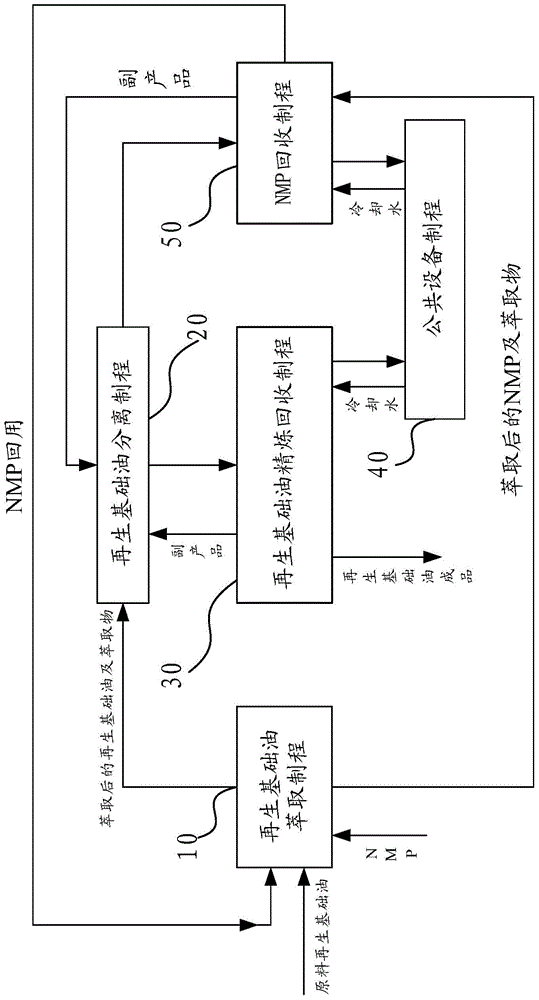

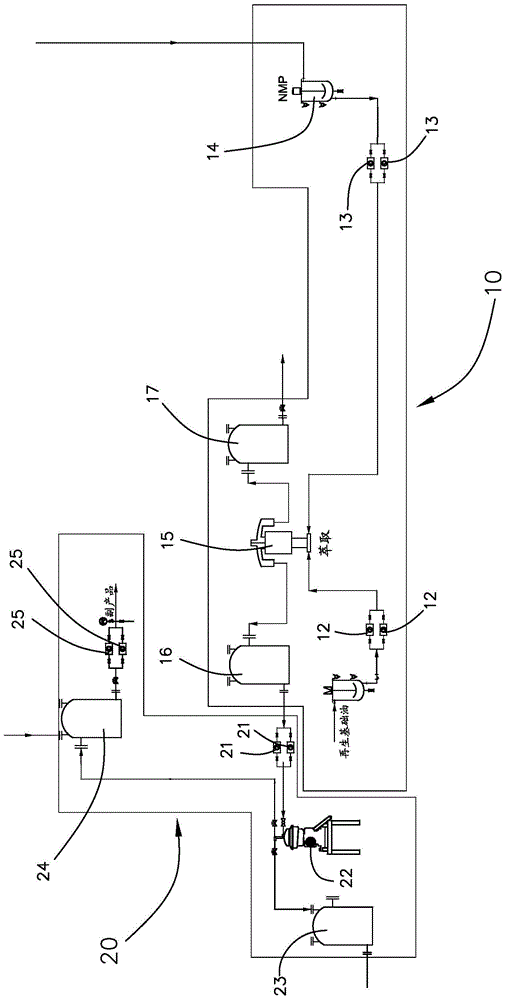

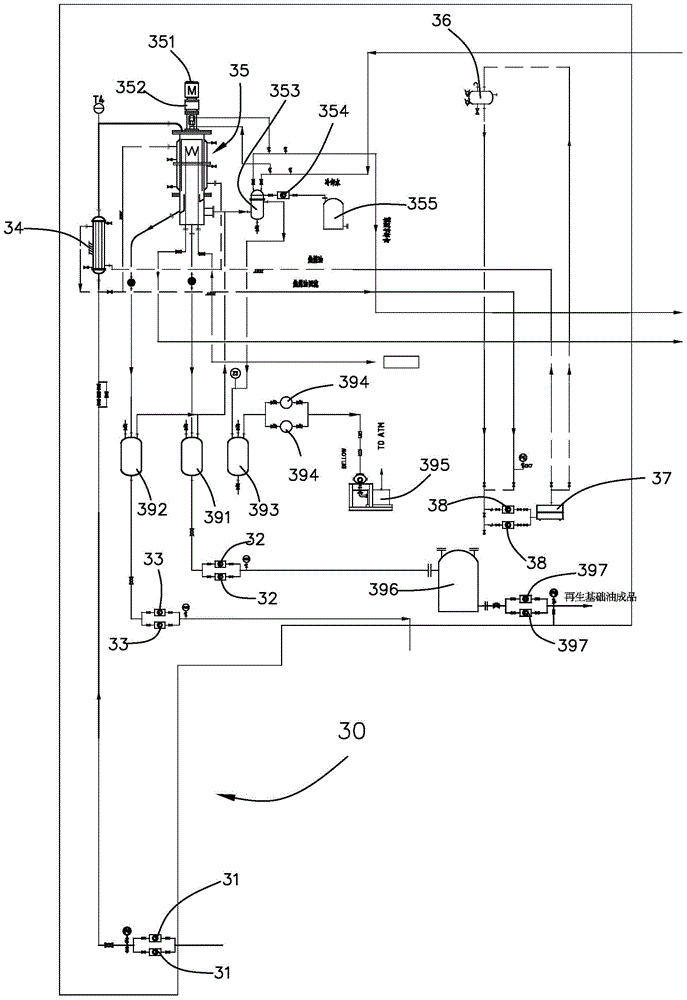

[0097] see Figure 1 to Figure 5 As shown, the preferred embodiment of the present invention includes a regenerated base oil extraction process (Re-refined base oil extraction process) 10, a regenerated base oil centrifugal separation process (High speed centrifuge separation process for re-refined base oil) 20, a regenerated base oil The oil refining recovery process (Re-refined base oil recovery process) 30 and the utility facility process (Utility facility process) 40 will be described in detail below.

[0098] The regenerated base oil extraction process 10 is used to mix the regenerated base oil with NMP (N-Methyl Pyrrolidinone, N-Methyl Pyrrolidinone) for desulfurization and removal of aromatics.

[0099] The equipment used in the regenerative base oil extraction process 10 includes a regenerative base oil blending heating tank 11, several material delivery pumps 12 / 13, an NMP storage tank 14 with a heater inside, a centrifugal extractor (Centrifugal Extractor) 15, a rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com