Method for preparing epoxidized soybean oil by using lipase catalysis

A technology for the preparation of epoxidized soybean oil and catalysis, which is applied in the field of preparation of epoxidized soybean oil, can solve the problems of low production energy consumption, and achieve the effects of less by-products, high product purity, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

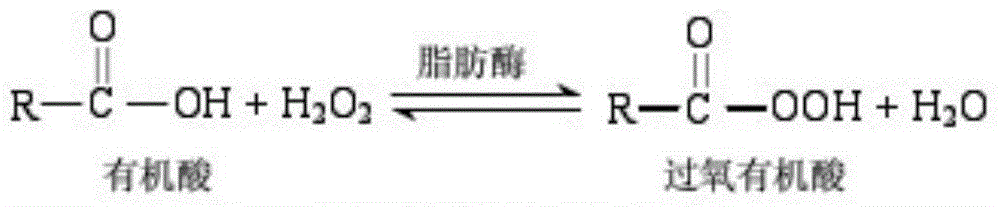

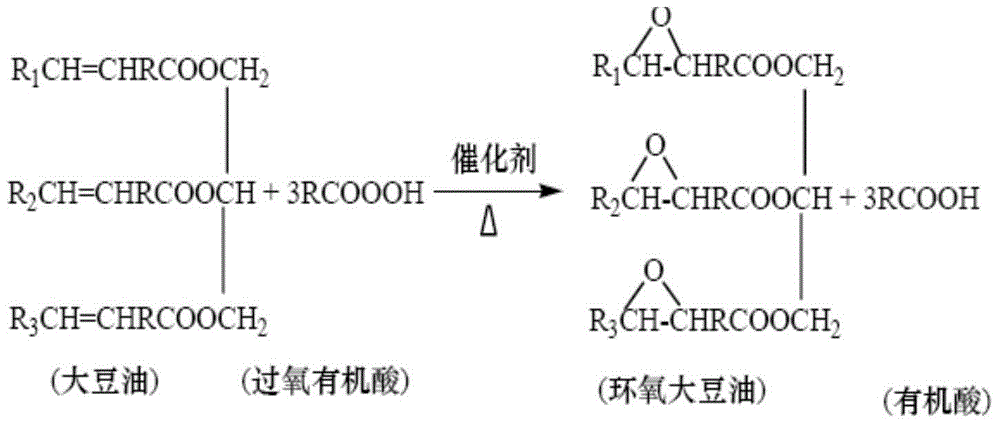

Method used

Image

Examples

Embodiment 1

[0027] In the hydrogen peroxide solution whose mass concentration is 30%, add 0.15wt% stabilizer EDTA, start to stir, after it dissolves completely, add urea, the molar ratio of described urea and hydrogen peroxide is 1:1.1, in Under constant stirring, heat up to 32°C, wait until urea is completely dissolved, keep warm for 25 minutes, then cool to -5°C for crystallization for 4 hours, obtain white crystals after suction filtration, dry at 50°C for 2 hours to obtain urea hydrogen peroxide.

Embodiment 2

[0029] In the hydrogen peroxide solution whose mass concentration is 40%, add 0.25wt% stabilizer EDTA, start to stir, after it dissolves completely, add urea, the molar ratio of described urea and hydrogen peroxide is 1:1.1, in Under constant stirring, heat up to 35°C, wait until urea is completely dissolved, keep it warm for 30 minutes, then cool to -5°C for crystallization for 5 hours, obtain white crystals after suction filtration, dry at 60°C for 2 hours to obtain urea hydrogen peroxide.

Embodiment 3

[0031] Mix 200g soybean crude oil, 1g stearic acid, 1g palmitic acid, 1g Tween 20, 1g Span 80, and 5g lipase evenly, stir and heat up to 20°C, then add 10g urea hydrogen peroxide, and react for 5h, Sampling, centrifugation, alkali washing and water washing for three times, and finally drying with calcium chloride to obtain epoxidized soybean oil product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com