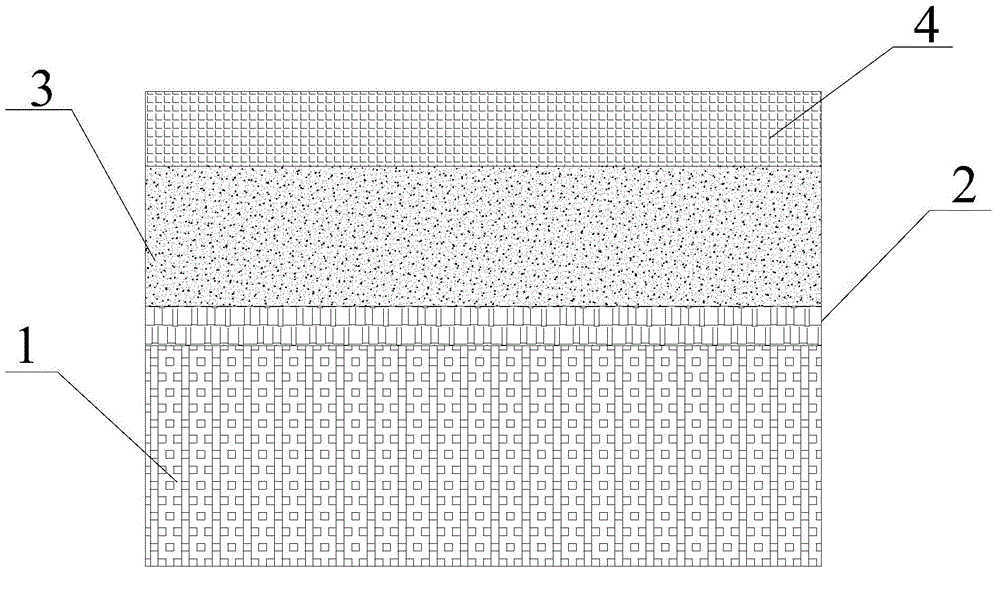

Thallium-doped cesium iodide composite film and preparation method thereof

A composite film, cesium iodide technology, applied in vacuum evaporation plating, coating, sputtering plating and other directions, can solve the problems of high production cost, limited luminous intensity, limitations, etc., and achieve the effect of strong blue light emission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Rinse the silicon sheet twice with pure water, then ultrasonically clean it in alcohol for 10 minutes, take it out and dry it naturally for later use;

[0023] 2. Use a copper plate as the target material, and deposit a copper film layer with a thickness of 10nm on the Si sheet at a rate of 0.02-0.5nm / s by ion beam sputtering;

[0024] Three, use commercially available CsI:Tl single crystal again as target material, deposit the CsI:Tl film layer that thickness is 300nm on the copper thin film layer surface with the method for ion beam sputtering;

[0025] 4. Finally use SiO 2 As the target material, a moisture-proof protective film with a thickness of 50nm was deposited on the surface of the CsI:Tl film layer by ion beam sputtering.

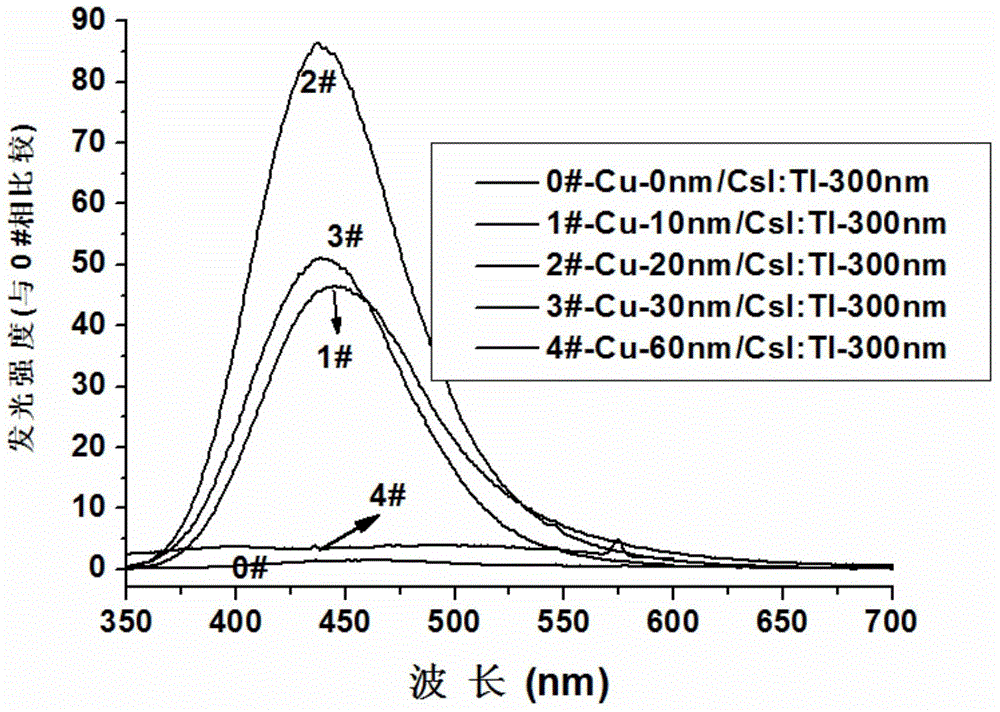

[0026] The sample prepared in this embodiment is marked as 1#, and its luminous properties are as follows: image 3 shown.

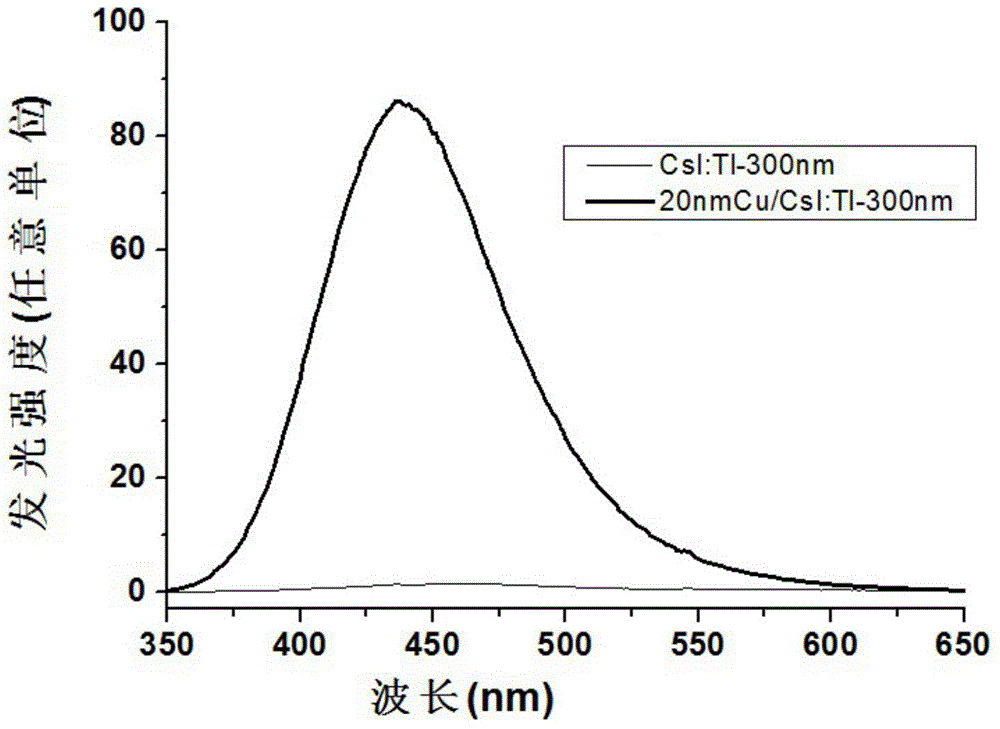

Embodiment 2

[0030] 1. Rinse the Si sheet twice with pure water, then ultrasonically clean it in acetone for 10 minutes, take it out and dry it naturally for later use;

[0031] 2. Use a copper plate as the target material, and deposit a copper film layer with a thickness of 20nm on the Si sheet at a rate of 0.02-0.5nm / s by ion beam sputtering;

[0032] Three, use commercially available CsI:Tl single crystal again as target material, deposit the CsI:Tl film layer that thickness is 300nm on the copper thin film layer surface with the method for ion beam sputtering;

[0033] 4. Finally use SiO 2 The ceramic target is used as the target material, and a moisture-proof protective film with a thickness of 50nm is deposited on the surface of the CsI:Tl film layer by ion beam sputtering.

[0034] The sample prepared in this embodiment is marked as 2#, and its luminous properties are as follows: image 3 shown.

Embodiment 3

[0036] 1. Rinse the quartz sheet twice with pure water, then ultrasonically clean it in acetone for 10 minutes, take it out and dry it naturally for later use;

[0037] 2. Use a copper plate as the target material, and deposit a copper film layer with a thickness of 30nm on the quartz plate at a rate of 0.02-0.5nm / s by ion beam sputtering;

[0038] Three, use commercially available CsI:Tl single crystal again as target material, deposit the CsI:Tl film layer that thickness is 300nm on the copper thin film layer surface with the method for ion beam sputtering;

[0039] 4. Finally use SiO 2 The ceramic target is used as the target material, and a moisture-proof protective film with a thickness of 50nm is deposited on the surface of the CsI:Tl film layer by ion beam sputtering.

[0040] The sample prepared in this embodiment is marked as 3#, and its luminous properties are as follows: image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com