Method for preparing ordered micropore structure on stainless steel surface

A technology of microporous structure and stainless steel, which is applied in the field of surface microstructure preparation, can solve the problems of unsatisfactory effect of functional materials, peeling of aluminum coating, uneven distribution, etc., and achieve the effect of uniform pore size, simple equipment and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

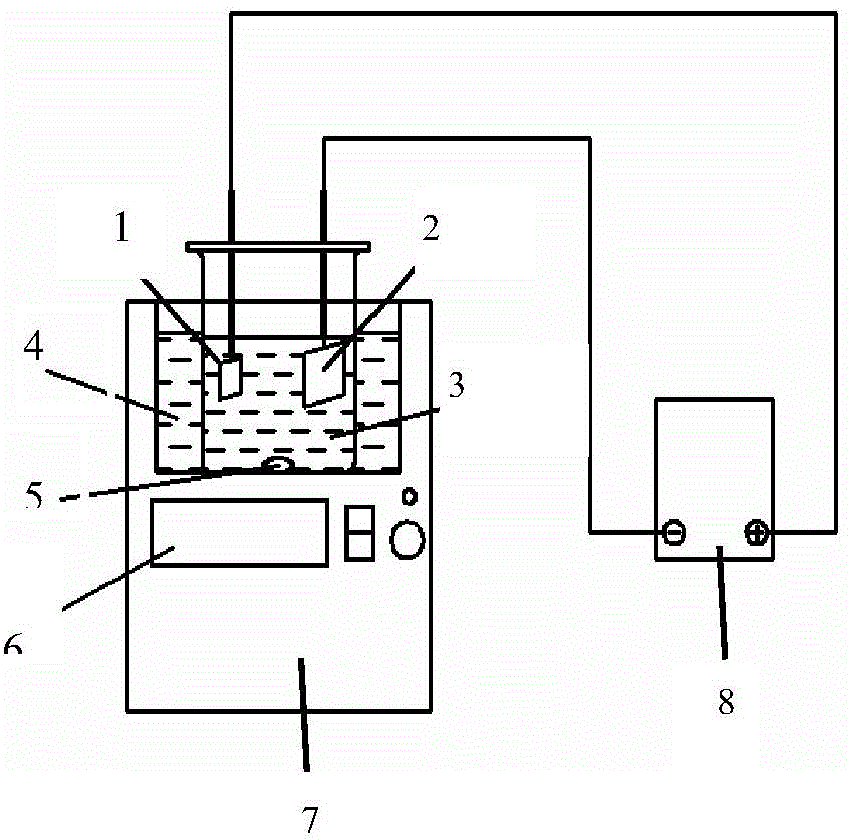

[0032] The preparation method of the ordered microporous structure on the surface of stainless steel mainly comprises the following steps:

[0033] (1) Stainless steel pretreatment:

[0034]1) Wire-cut a 1mm thick stainless steel plate into a sample of 30mm×20mm;

[0035] 2) Put the stainless steel into the 836 type metal cleaning solution for ultrasonic cleaning for 15 minutes, and perform degreasing treatment;

[0036] 3) Use WYK-15010K DC stabilized voltage and current power supply to electrochemically polish the degreased stainless steel to obtain a mirror surface; electrochemical polishing process: the stainless steel sample is used as the anode, the high-purity graphite sheet is used as the cathode, and the area ratio of the cathode to the anode is 3 : 1, cathode and anode spacing 50mm, electrolytic polishing solution concentration is 300ml / L H 2 SO 4 , 600ml / L H 3 PO 4 , an aqueous solution composed of 30ml / L glycerol, the temperature of the polishing solution is 8...

Embodiment 2

[0040] The preparation method of the ordered microporous structure on the surface of stainless steel mainly comprises the following steps:

[0041] (1) Stainless steel pretreatment:

[0042] 1) Wire-cut a 1mm thick stainless steel plate into a sample of 30mm×20mm;

[0043] 2) Put the stainless steel into the 836 type metal cleaning solution for ultrasonic cleaning for 15 minutes, and perform degreasing treatment;

[0044] 3) Use WYK-15010K DC stabilized voltage and current power supply to electrochemically polish the degreased stainless steel to obtain a mirror surface; electrochemical polishing process: the stainless steel sample is used as the anode, the high-purity graphite sheet is used as the cathode, and the area ratio of the cathode to the anode is 3 : 1, cathode and anode spacing 50mm, electrolytic polishing solution concentration is 300ml / L H 2 SO 4 , 600ml / L H 3 PO 4 , an aqueous solution composed of 30ml / L glycerol, the temperature of the polishing solution is ...

Embodiment 3

[0048] The preparation method of the ordered microporous structure on the surface of stainless steel mainly comprises the following steps:

[0049] (1) Stainless steel pretreatment:

[0050] 1) Wire-cut a 1mm thick stainless steel plate into a sample of 30mm×20mm;

[0051] 2) Put the stainless steel into the 836 type metal cleaning solution for ultrasonic cleaning for 15 minutes, and perform degreasing treatment;

[0052] 3) Use WYK-15010K DC stabilized voltage and current power supply to electrochemically polish the degreased stainless steel to obtain a mirror surface; electrochemical polishing process: the stainless steel sample is used as the anode, the high-purity graphite sheet is used as the cathode, and the area ratio of the cathode to the anode is 3 : 1, cathode and anode spacing 50mm, electrolytic polishing solution concentration is 300ml / L H 2 SO 4 , 600ml / L H 3 PO 4 , an aqueous solution composed of 30ml / L glycerol, the temperature of the polishing solution is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com