Method for electrochemical deposition of epitaxial CeO2 thick film on metal substrate

A technology of metal baseband and deposition method, applied in the direction of electrolytic inorganic material coating, etc., can solve the problems of micro-cracks, cost increase, etc., and achieve the effect of smooth surface, reduction of preparation cost, and refinement of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

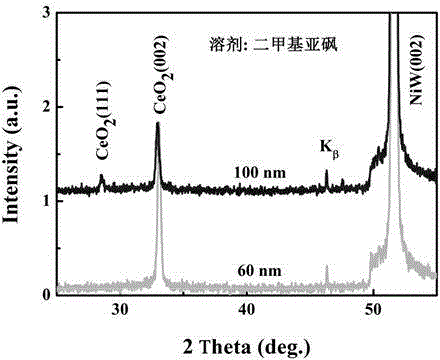

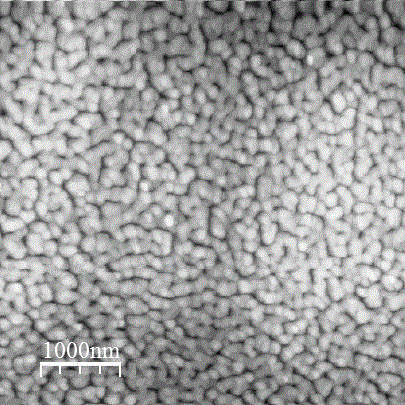

[0025] In this example, see figure 1 and figure 2 , epitaxial CeO on metal substrate 2 The electrochemical deposition method of a thick film, the specific process steps are:

[0026]a. Prepare the solution: First, weigh 0.0986g of cerium chloride medicine with a balance, place it in a beaker dried after ultrasonic cleaning, and then dilute the total concentration of cations to 2 mmol / L with dimethyl sulfoxide. After the solution is prepared, use Seal with plastic wrap, and stir on a magnetic stirrer for about 10 hours to fully dissolve the solute;

[0027] b. Electrodeposition process: Pour the solution obtained in step a into a self-made glass container, use the NiW substrate as the cathode, and the FTO conductive glass as the anode. Before deposition, the NiW substrate is ultrasonically cleaned in acetone and absolute ethanol for 5 minutes. mode with a current density of 0.2 mA / cm 2 , the deposition time is 4~7min, and the thickness of the deposited film is 60~100 nm. T...

Embodiment 2

[0031] This embodiment is basically the same as Embodiment 1, especially in that:

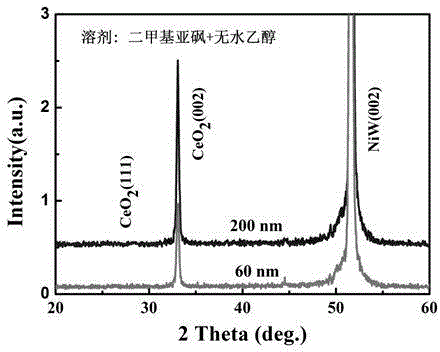

[0032] In this example, see Figure 3~Figure 5 , epitaxial CeO on metal substrate 2 The electrochemical deposition method of a thick film, the specific process steps are:

[0033] a. Configuration solution: first weigh 0.0986g of cerium chloride with a balance, place it in a beaker dried after ultrasonic cleaning, and then dilute the total concentration of cations to 2 mmol / L, after the solution configuration is completed, seal it with plastic wrap, put it on a magnetic stirrer and stir for about 10 hours, so that the solute is fully dissolved;

[0034] b. Electrodeposition process: Pour the solution obtained in step a into a self-made glass container, use the NiW substrate as the cathode, and the FTO conductive glass as the anode. Before deposition, the NiW substrate is ultrasonically cleaned in acetone and absolute ethanol for 5 minutes. mode with a current density of 0.2 mA / cm 2 , the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com