Composite optical fiber with multi-component phosphate glass cladding/selenium and tellurium compound semiconductor fiber core

A technology of phosphate glass and composite materials, which is applied in the direction of clad optical fiber, optical waveguide and light guide, glass manufacturing equipment, etc., to achieve the effect of low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Phosphate glass cladding Se 1-x Te x (x=0.2) The preparation and method of semiconductor core fiber are as follows:

[0028] (1) Cladding multi-component phosphate glass melting: adopting traditional melting-annealing method to fuse bulk multi-component phosphate glass. In terms of weight percentage, the glass material raw material formula consists of the following substances:

[0029] P 2 O 5 : 55%

[0030] K 2 O: 15%

[0031] BaO: 10%

[0032] Al 2 O 3 : 20%

[0033] Weigh the raw materials according to the ratio, mix them evenly and melt them in a pot at 1100~1300℃, and obtain bulk phosphate glass after precision annealing.

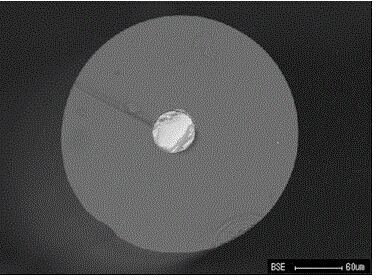

[0034] (2) Processing of multi-component phosphate glass: the annealed bulk cladding glass is processed into a cylinder with a diameter of 25 mm and a length of 80 mm, and then a diameter of 2.5 mm and a depth of 60 mm are drilled in the middle of the cylindrical glass along the axis of the cylinder The round hole does not penetrate the entire phosphate ...

Embodiment 2

[0039] Phosphate glass cladding Se 1-x Te x (x=0.0) The preparation and method of semiconductor core fiber are as follows:

[0040] (1) Cladding multi-component phosphate glass melting: adopting traditional melting-annealing method to fuse bulk multi-component phosphate glass. In terms of weight percentage, the glass material raw material formula consists of the following substances:

[0041] P 2 O 5 : 55%

[0042] K 2 O: 15%

[0043] BaO: 10%

[0044] Al 2 O 3 : 20%

[0045] Weigh the raw materials according to the ratio, mix them evenly and melt them in a pot at 1100~1300℃, and obtain bulk phosphate glass after precision annealing.

[0046] (2) Processing of multi-component phosphate glass: the annealed bulk cladding glass is processed into a cylinder with a diameter of 25 mm and a length of 80 mm, and then a diameter of 2.5 mm and a depth of 60 mm are drilled in the middle of the cylindrical glass along the axis of the cylinder The round hole does not penetrate the entire phosphate ...

Embodiment 3

[0050] Phosphate glass cladding Se 1-x Te x (x=1.0) The preparation and method of semiconductor core fiber are as follows:

[0051] (1) Cladding multi-component phosphate glass melting: adopting traditional melting-annealing method to fuse bulk multi-component phosphate glass. In terms of weight percentage, the glass material raw material formula consists of the following substances:

[0052] P 2 O 5 : 55%

[0053] K 2 O: 15%

[0054] BaO: 10%

[0055] Al 2 O 3 : 20%

[0056] Weigh the raw materials according to the ratio, mix them evenly and melt them in a pot at 1100~1300℃, and obtain bulk phosphate glass after precision annealing.

[0057] (2) Processing of multi-component phosphate glass: the annealed bulk cladding glass is processed into a cylinder with a diameter of 25 mm and a length of 80 mm, and then a diameter of 2.5 mm and a depth of 60 mm are drilled in the middle of the cylindrical glass along the axis of the cylinder The round hole does not penetrate the entire phosphate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com