Preparation method of lithium vanadium phosphate and fluorination lithium vanadium phosphate composite positive pole material

A technology of fluorinated lithium vanadium phosphate and composite cathode material, which is used in battery electrodes, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

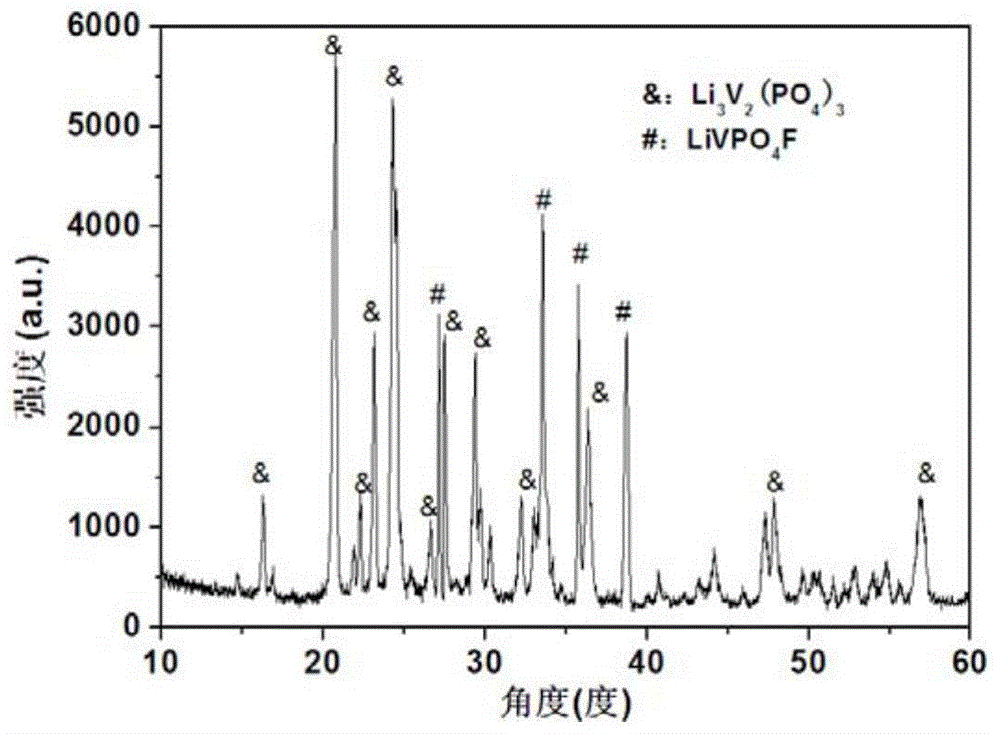

[0019] (1) Weigh vanadium pentoxide, aluminum nitrate, ammonium dihydrogen phosphate, and sucrose according to the molar ratio of V:Al:P:C of 0.95:0.05:1:2.0. After dispersing and grinding with alcohol, vacuum drying and sintering under nitrogen atmosphere, the sintering temperature is 700°C, the holding time is 10h, and the carbon pre-coated, Al ion-doped V 0.95 AL 0.05 PO 4 / C precursor;

[0020] (2) According to the stoichiometric ratio V 0.95 m 0.05 PO 4 / C:Li:F:P:C=1.2:0.6:0.8:0.2:0.2 Weigh the V obtained in step (1) 0.95 AL 0.05 PO 4 / C precursor, lithium carbonate, LiF, NH 4 h 2 PO 4 As well as the graphene conductive paste, the ball milling dispersion treatment is also carried out in alcohol, and the sintering treatment is carried out under a nitrogen atmosphere after vacuum drying. The sintering temperature is 650 degrees, and the holding time is 6h. Lithium vanadium phosphate and fluorinated lithium vanadium phosphate composite cathode materials co-modifie...

Embodiment 2

[0022] (1) Weigh ammonium metavanadate, iron nitrate, ammonium dihydrogen phosphate, and phenolic resin according to the molar ratio of V:Fe:P:C of 0.85:0.15:1:1.5. After dispersing and grinding with alcohol, vacuum drying and sintering under nitrogen atmosphere, the sintering temperature is 750°C, the holding time is 6h, and the carbon pre-coated, Fe ion-doped V 0.85 Fe 0.15 PO 4 / C precursor;

[0023] (2) According to the stoichiometric ratio V 0.85 Fe 0.15 PO 4 / C:Li:F:P:C=1.4:1.2:0.6:0.4:0.8 Weigh the V obtained in step (1) 0.85 Fe 0.15 PO 4 / C precursor, lithium hydroxide, LiF, NH 4 h 2 PO 4 As well as the graphene conductive paste, it is also ball-milled and dispersed in alcohol. After vacuum drying, it is sintered in a nitrogen atmosphere. The sintering temperature is 700 degrees, and the holding time is 4h. Lithium vanadium phosphate and fluorinated lithium vanadium phosphate composite cathode materials co-modified by pyrolysis carbon;

Embodiment 3

[0025] (1) Weigh ammonium metavanadate, chromium nitrate, ammonium dihydrogen phosphate, and glucose according to the molar ratio of V:Cr:P:C of 0.9:0.1:1:1.2. After dispersing and grinding with methanol, vacuum drying and sintering under nitrogen atmosphere, the sintering temperature is 800°C, the holding time is 4h, and the carbon pre-coated, Cr ion-doped V 0.9 Cr 0.1 PO 4 / C precursor;

[0026] (2) According to the stoichiometric ratio V 0.9 Cr 0.1 PO 4 / C:Li:F:P:C=1.6:1.8:0.4:0.6:1.0 Weigh the V obtained in step (1) 0.9 Cr 0.1 PO 4 / C precursor, lithium acetate, LiF, NH 4 h 2 PO 4 As well as the graphene conductive paste, the ball mill dispersion treatment is also carried out in methanol, and the sintering treatment is carried out under a nitrogen atmosphere after vacuum drying. The sintering temperature is 750 degrees, and the holding time is 2h. Lithium vanadium phosphate and fluorinated lithium vanadium phosphate composite cathode materials co-modified by pyr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com