Fluorescent carbon quantum dots as well as preparation method and application thereof

A carbon quantum dot and fluorescence technology, applied in the field of fluorescent carbon quantum dots, can solve the problems of complex operation, high cost, unfavorable scale production, etc., and achieve the effects of simple operation, low price and stable optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

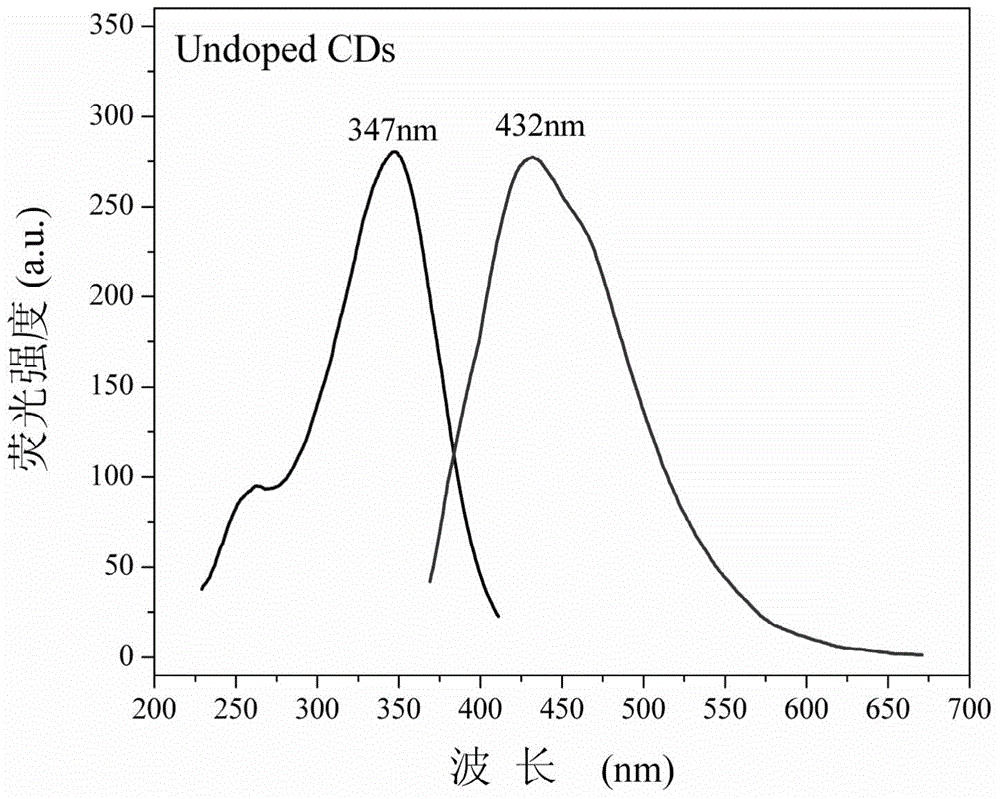

Embodiment 1

[0041] Step 1, weigh 0.2682g of malic acid in a microwave reactor, then add 10mL of secondary water, stir well, and ultrasonically obtain a clear solution;

[0042] Step 2, the microwave reactor was placed in a microwave oven (700 watts) and reacted for 20 minutes under high heat to obtain a light yellow solid;

[0043] Step 3, take out the microwave reactor, cool naturally, add 20mL of secondary water into it, stir and dissolve to obtain a light yellow solution, remove insoluble matter by filtration to obtain a clear light yellow solution, and dialyze in a glass container through a 500-1000Da dialysis bag Treat for at least 3 days to remove impurities to obtain a pure aqueous solution of fluorescent carbon quantum dots;

[0044] In step 4, the fluorescent carbon quantum dot aqueous solution is freeze-dried to obtain the fluorescent carbon quantum dot, and its relative quantum yield (using quinine sulfate as a standard) is 9.86%.

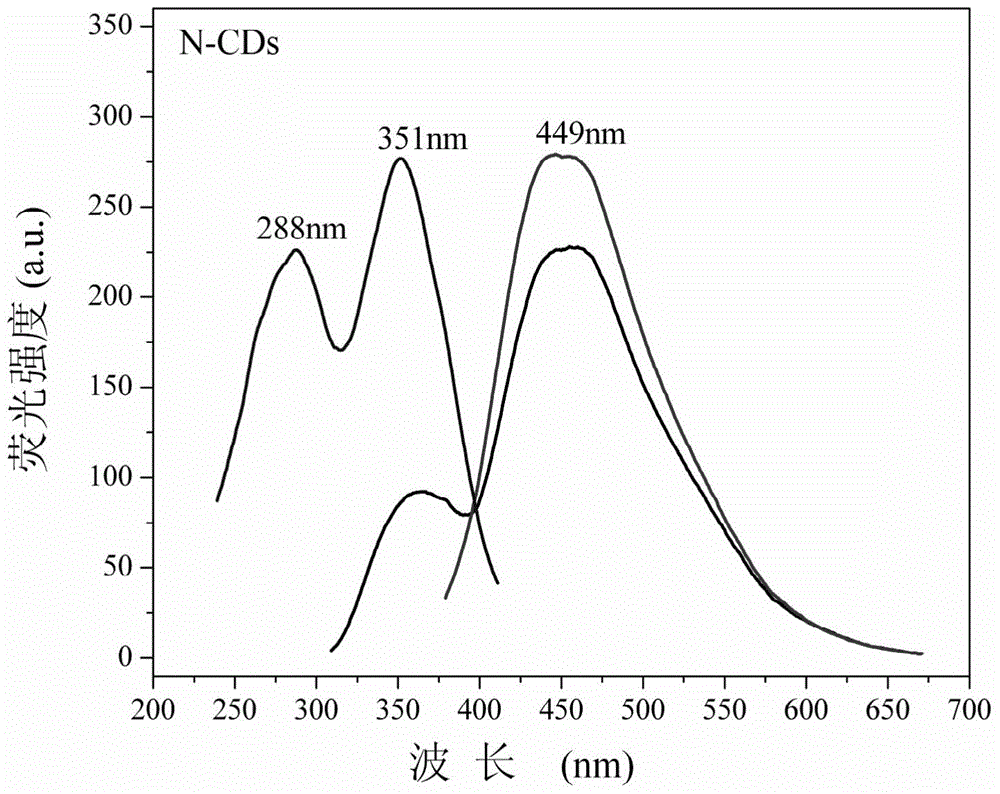

Embodiment 2

[0046] Weigh 0.2682g of malic acid in a microwave reactor, add 10mL of secondary water, then add 121μL of ethanolamine and stir thoroughly, and ultrasonically obtain a clear solution;

[0047] Step 2, the microwave reactor was placed in a microwave oven (700 watts) and reacted for 10 minutes under high heat to obtain a light brown solid;

[0048] Step 3, take out the microwave reactor, cool naturally, add 20mL of secondary water into it, stir and dissolve to obtain a light brown solution, remove insoluble matter by filtration to obtain a clear light brown solution, and dialyze in a glass container through a 500-1000Da dialysis bag Treat for at least 3 days to remove impurities to obtain a pure aqueous solution of fluorescent carbon quantum dots;

[0049] In step 4, the fluorescent carbon quantum dot aqueous solution was freeze-dried to obtain the fluorescent carbon quantum dot, and its relative quantum yield (taking quinine sulfate as a standard) was 15.13%.

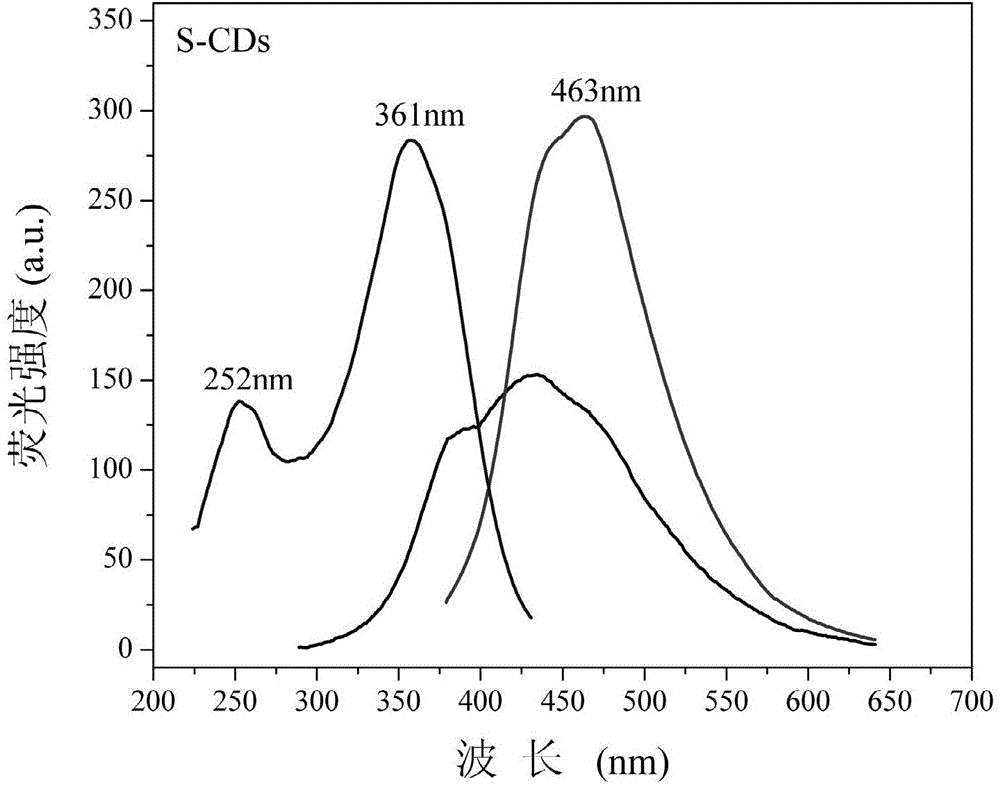

Embodiment 3

[0051] Weigh 0.2682g of malic acid in a microwave reactor, add 10mL of secondary water, then add 163μL of ethanesulfonic acid, stir well, and ultrasonically obtain a clear solution;

[0052] Step 2, the microwave reactor was placed in a microwave oven (700 watts) and reacted for 5 minutes under high heat to obtain a light brown solid;

[0053] Step 3, take out the microwave reactor, cool naturally, add 20mL of secondary water into it, stir and dissolve to obtain a light brown solution, remove insoluble matter by filtration to obtain a clear light brown solution, and dialyze in a glass container through a 500-1000Da dialysis bag Treat for at least 3 days to remove impurities to obtain a pure aqueous solution of fluorescent carbon quantum dots;

[0054] In step 4, the fluorescent carbon quantum dot aqueous solution is freeze-dried to obtain the fluorescent carbon quantum dot, and its relative quantum yield (taking quinine sulfate as a standard) is 5.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com