Compound microbial fertilizer having high nutrient content and preparation method thereof

A technology of compound microorganisms and nutrient content, applied in the field of compound microorganism fertilizers with high nutrient content, can solve the problems of affecting fertilizer quality and decreasing fertilizer efficiency, and achieve the effects of obvious plant growth promoting effect, improving quality and facilitating promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

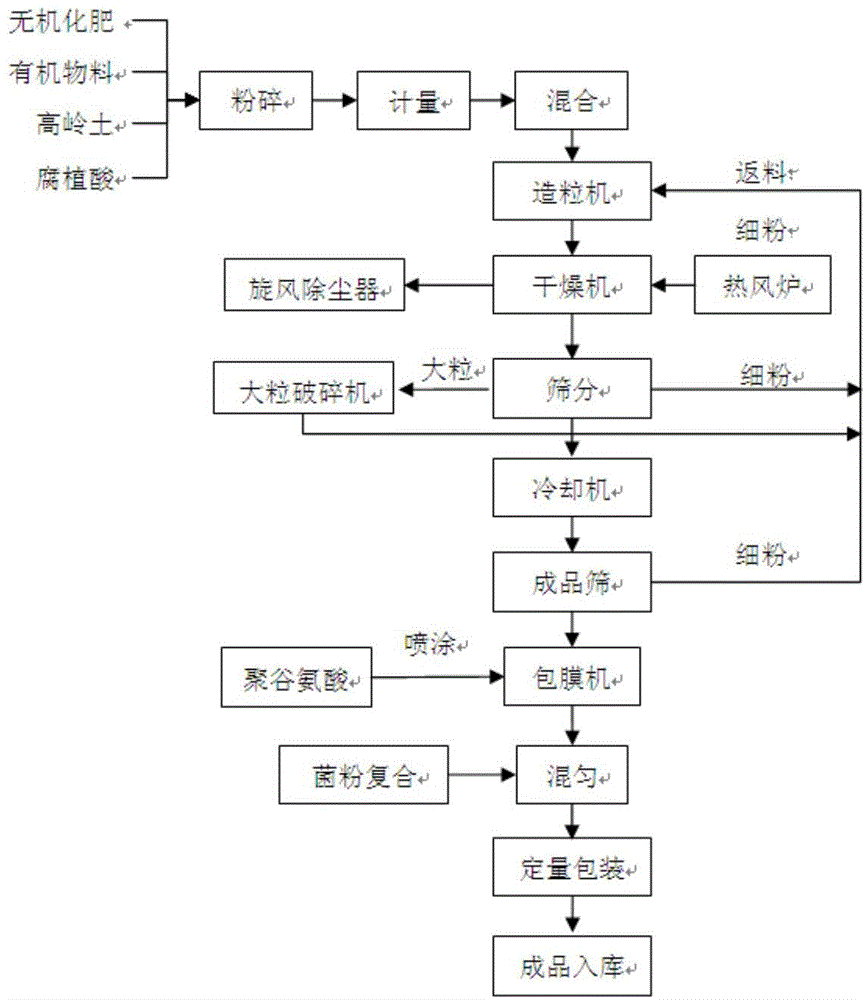

Method used

Image

Examples

Embodiment 1

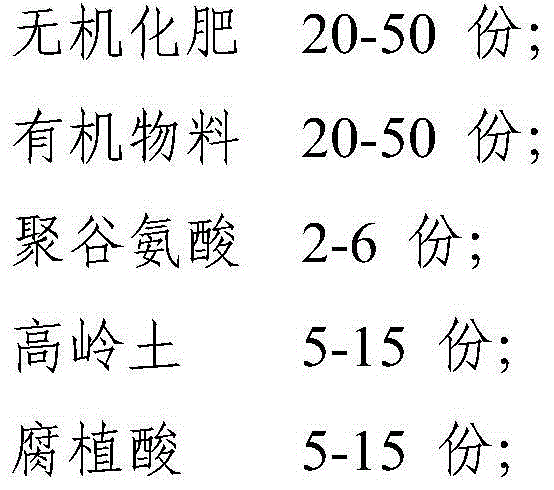

[0048] This embodiment provides a composite microbial fertilizer, the formula of which is as follows:

[0049]

[0050] Among them, the inorganic fertilizer is composed of the following components by weight: 10 parts of urea, 10 parts of monoammonium phosphate, 15 parts of potassium sulfate, and 5 parts of superphosphate;

[0051] Among them, the organic material is composed of the following components by weight: 10 parts of fermented furfural residue, 10 parts of fermented mushroom residue, 10 parts of fermented grape skin residue, and 5 parts of plant ash;

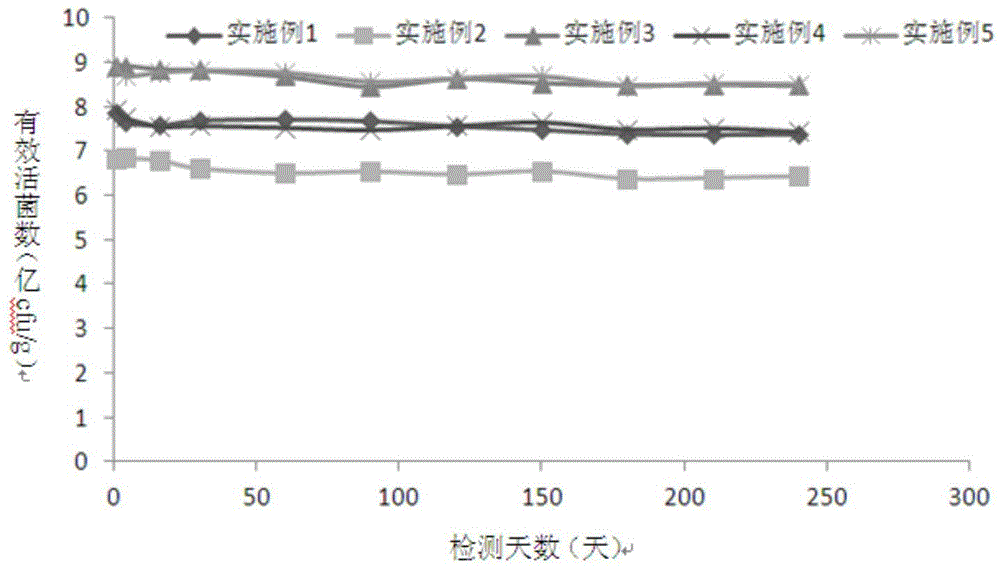

[0052] Among them, the compound microbial strains contain Bacillus megaterium, Bacillus Laterosporus, Pseudomonas aeruginosa, Bacillus licheniformis and Actinomycetes at a concentration ratio of 1:1:1:1.5:2, and the effective activity per gram of the fertilizer The number of bacteria is 7×10 8 Around cfu.

[0053] The total nutrient content of the compound microbial fertilizer obtained in this example is 20.3%, and the organic m...

Embodiment 2

[0055] This embodiment provides a composite microbial fertilizer, the formula of which is as follows:

[0056]

[0057] Among them, the inorganic fertilizer is composed of the following components by weight: 12 parts of urea, 5 parts of ammonium sulfate, 15 parts of monoammonium phosphate, 8 parts of potassium sulfate, and 10 parts of superphosphate;

[0058] Among them, the organic material is composed of the following components by weight: 15 parts of fermented furfural residue, 15 parts of fermented grape skin residue, and 10 parts of plant ash;

[0059] Wherein, the composite microbial strain contains Bacillus megaterium, Bacillus Laterosporus, Pseudomonas aeruginosa, Bacillus licheniformis and Actinomycetes at a concentration ratio of 1:1:1:2:2.5, and each gram of the fertilizer The effective number of viable bacteria is 6×10 8 Around cfu.

[0060] The total nutrient content of the compound microbial fertilizer obtained in this example is 16.95%, and the organic matter content is...

Embodiment 3

[0062] This embodiment provides a composite microbial fertilizer, the formula of which is as follows:

[0063]

[0064] Among them, the inorganic fertilizer is composed of the following components by weight: 10 parts of urea, 10 parts of monoammonium phosphate, 8 parts of potassium chloride, and 2 parts of superphosphate;

[0065] Among them, 10 parts of organic material fermented furfural residue, 10 parts of fermented mushroom residue, 10 parts of fermented grape skin residue, and 10 parts of plant ash;

[0066] Among them, the compound microbial strains contain Bacillus megaterium, Bacillus Laterosporus, Pseudomonas aeruginosa, Bacillus licheniformis and Actinomycetes at a concentration ratio of 1:1:1:2:3, and the effective activity per gram of the fertilizer The number of bacteria is 8×10 8 Around cfu.

[0067] The total nutrient content of the compound microbial fertilizer obtained in this example is 16%, and the organic matter content is 21.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com