Canoderma lucidum culture medium and preparation method thereof

The technology of a cultivation medium and ganoderma lucidum, applied in the field of ganoderma cultivation substrate and its preparation, can solve the problems of low utilization rate of nutrients, high cost of ganoderma cultivation substrate, long cultivation period, etc., and achieve nutritional balance, low cost and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

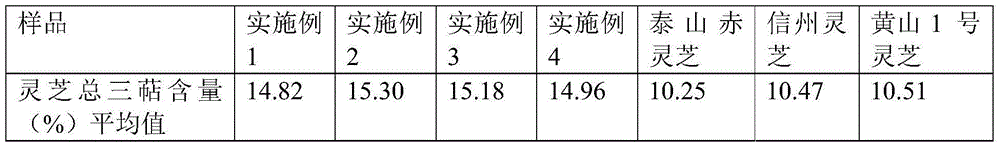

Examples

Embodiment 1

[0033]A ganoderma cultivation substrate is prepared by mixing main materials and auxiliary materials, and the main materials account for 38% of the total weight of the substrate. The mass fraction of main ingredients is composed of 40% of mulberry branches, 20% of soybean hulls, and 40% of wood chips, and the mass fraction of auxiliary materials is composed of (100% in total, the same below): 15% of rapeseed cake, 6% of ganoderma fungus powder , 3% calcium carbonate, 1% fermented silkworm manure, 0.1% sodium humate, and the balance is Lycium chinensis powder. The particle fineness of mulberry branches, soybean hulls and fermented silkworm excrement is 4-6 mesh. Lycium chinensis powder is dried leaves and stems of Lycium chinensis and ground into powder, and the particle size is controlled within the range of 18-30mm. The fermented silkworm dung is pre-dried in the sun for 3-5 days, then crushed and passed through a 4-6 mesh sieve. Ganoderma lucidum powder is a powder made fr...

Embodiment 2

[0042] A ganoderma cultivation substrate is prepared by mixing main materials and auxiliary materials, and the main materials account for 50% of the total weight of the substrate. The main material is mixed with soybean hulls and wood chips in a weight ratio of 1:3, and the mass fraction of auxiliary materials is composed of (100% in total, the same below): rapeseed cake 15%, ganoderma fungus powder 6%, granular activated carbon 4%, calcium carbonate 2%, fermented silkworm excrement 3%, sodium humate 0.1%, and the balance is Lycium chinensis powder. The particle fineness of mulberry branches, soybean hulls and fermented silkworm excrement is 4-6 mesh. Lycium chinensis powder is dried leaves and stems of Lycium chinensis and ground into powder, and the particle size is controlled within the range of 18-30mm. Fermented silkworm dung and granular activated carbon are pre-dried in the sun for 3-5 days, then crushed and passed through a 4-6 mesh sieve. Granular activated carbon i...

Embodiment 3

[0045] A ganoderma cultivation substrate is prepared by mixing main materials and auxiliary materials, and the main materials account for 50% of the total weight of the substrate. The main material is mixed with soybean hulls and wood chips in a weight ratio of 1:3, and the mass fraction of auxiliary materials is composed of (100% in total, the same below): rapeseed cake 15%, ganoderma fungus powder 3%, granular activated carbon 3%, calcium carbonate 2%, fermented silkworm excrement 3%, sodium humate 0.1%, and the balance is Lycium chinensis powder. The particle fineness of mulberry branches, soybean hulls and fermented silkworm excrement is 4-6 mesh. Lycium chinensis powder is dried leaves and stems of Lycium chinensis and ground into powder, and the particle size is controlled within the range of 18-30mm. Fermented silkworm dung and granular activated carbon are pre-dried in the sun for 3-5 days, then crushed and passed through a 4-6 mesh sieve. Granular activated carbon i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com