High-efficiency sapphire grinding liquid and preparation method thereof

A technology of grinding liquid and sapphire, which is applied in the field of grinding liquid, can solve the problems of low grinding efficiency of the grinding liquid, increase the difficulty of subsequent polishing, and uneven dispersion of the liquid film, so as to improve the grinding processing efficiency, shorten the processing time, and improve product quality. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

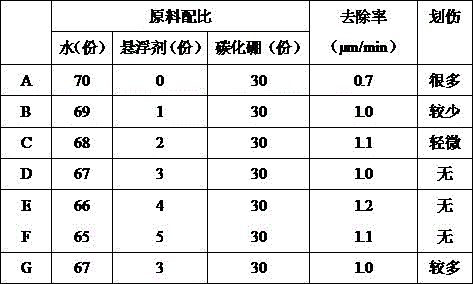

Embodiment 1

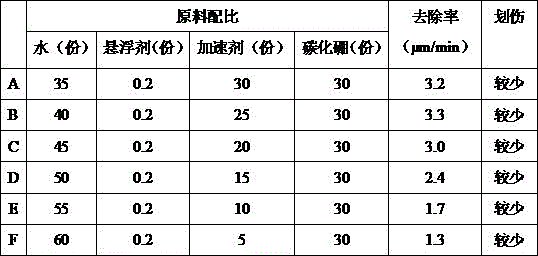

[0027] Prepare six grinds A, B, C, D, E, F:

[0028] Weigh the friction agent, suspending agent, accelerator and water according to the weight ratio, add 0.2 parts of hydroxyethyl cellulose to 35 parts, 40 parts, 45 parts, 50 parts, 55 parts, and 60 parts of water, dissolve completely, and stir Evenly, then add 30 parts of boron carbide with a particle size of 320 mesh (40~50μm), stir to make a suspension, add 30 parts, 25 parts, 20 parts, 15 parts, 10 parts, 5 parts of accelerator, add nitric acid Or adjust the pH value to 7.5 with sodium hydroxide, configure six parts of grinding liquid A, B, C, D, E, F, wherein the accelerator includes polyacrylate, acrylate polymer, ethanolamine, triethanolamine, propylene glycol, polyethylene Alcohol and nonylphenol polyoxyethylene ether, the weight ratio is: polyacrylate: acrylate polymer: ethanolamine: triethanolamine: propylene glycol: polyvinyl alcohol: nonylphenol polyoxyethylene ether=0.6:6:1: 1:2:3:1.

[0029] Grind the prepared ...

Embodiment 2

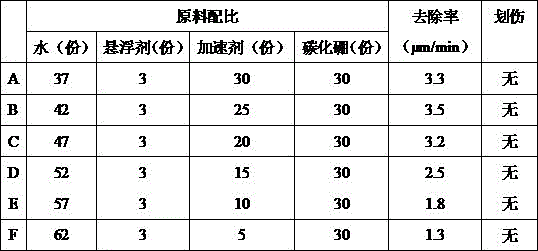

[0034] Prepare six grinds A, B, C, D, E, F:

[0035] Weigh friction agent, suspending agent, accelerator and water according to the weight ratio, add 3 parts of hydroxyethyl cellulose to 37 parts, 42 parts, 47 parts, 52 parts, 57 parts, and 62 parts of water, dissolve thoroughly, and stir Evenly, then add 30 parts of boron carbide with a particle size of 320 mesh (40~50μm), stir to make a suspension, add 30 parts, 25 parts, 20 parts, 15 parts, 10 parts, 5 parts of accelerator, add nitric acid Or adjust the pH value to 7.5 with sodium hydroxide, configure six parts of grinding liquid A, B, C, D, E, F, wherein the accelerator includes polyacrylate, acrylate polymer, ethanolamine, triethanolamine, propylene glycol, polyethylene Alcohol and nonylphenol polyoxyethylene ether, the weight ratio is: polyacrylate: acrylate polymer: ethanolamine: triethanolamine: propylene glycol: polyvinyl alcohol: nonylphenol polyoxyethylene ether=0.6:6:1: 1:2:3:1.

[0036] Grind the prepared sample...

Embodiment 3

[0041] Prepare six grinds A, B, C, D, E, F:

[0042]Weigh friction agent, suspending agent, accelerator and water according to the weight ratio, add 5 parts of hydroxyethyl cellulose to 35 parts, 40 parts, 45 parts, 50 parts, 55 parts, and 60 parts of water, dissolve thoroughly, and stir Evenly, then add 30 parts of boron carbide with a particle size of 320 mesh (40~50μm), stir to make a suspension, add 30 parts, 25 parts, 20 parts, 15 parts, 10 parts, 5 parts of accelerator, add nitric acid Or adjust the pH value to 7.5 with sodium hydroxide, configure six parts of grinding liquid A, B, C, D, E, F, wherein the accelerator includes polyacrylate, acrylate polymer, ethanolamine, triethanolamine, propylene glycol, polyethylene Alcohol and nonylphenol polyoxyethylene ether, the weight ratio is: polyacrylate: acrylate polymer: ethanolamine: triethanolamine: propylene glycol: polyvinyl alcohol: nonylphenol polyoxyethylene ether=0.6:6:1: 1:2:3:1.

[0043] Grind the prepared sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com