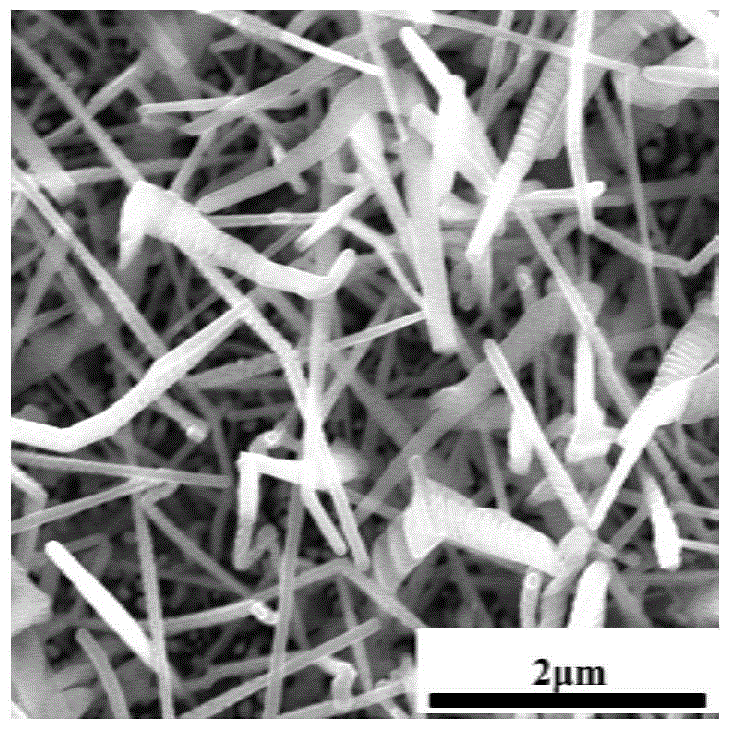

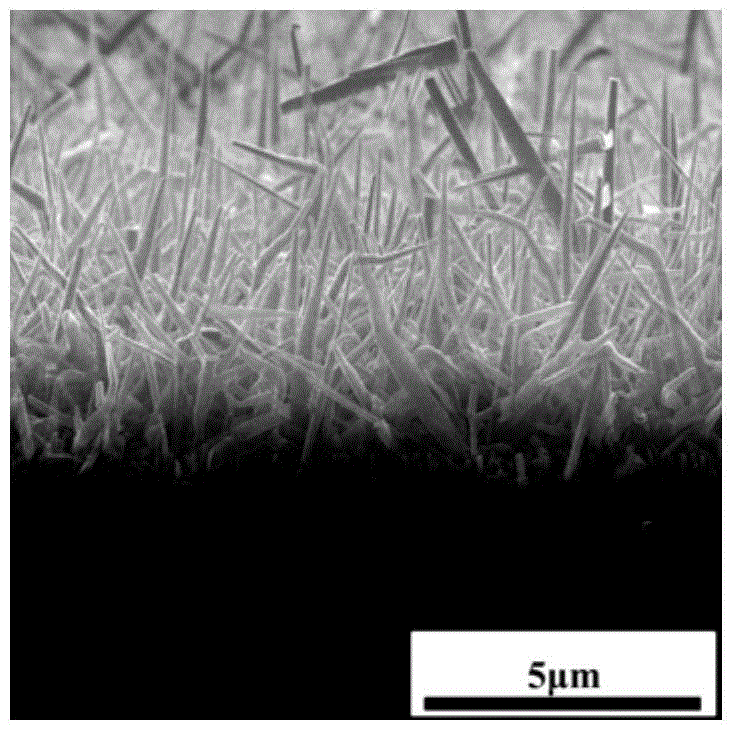

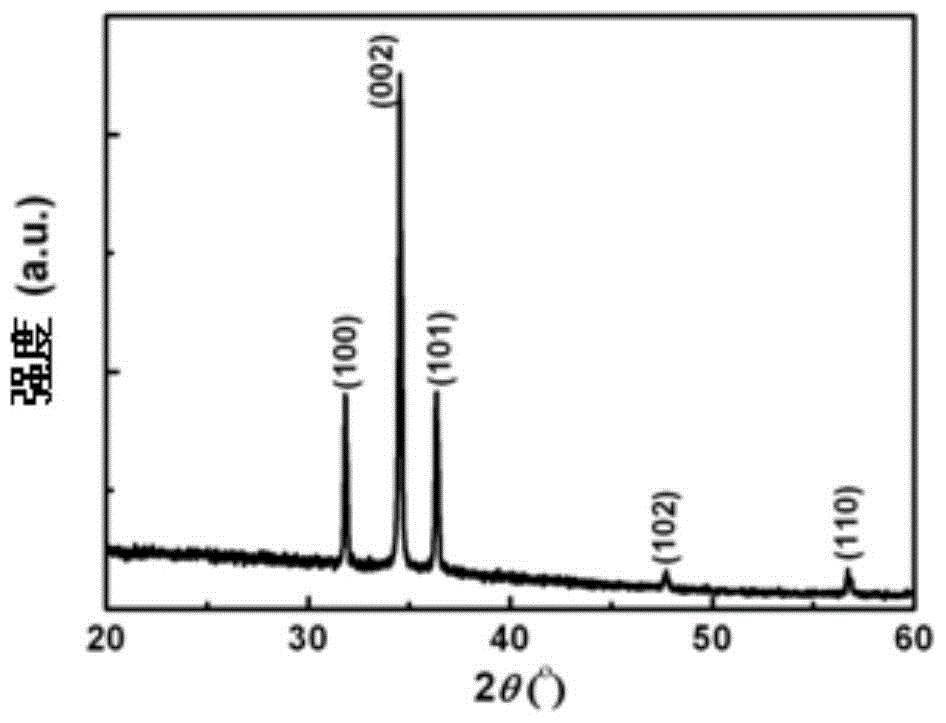

Preparation method of copper-doped ZnO nanorods by pulsed laser deposition

A zinc oxide nanorod, pulsed laser deposition technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc. Scope of application, simple raw materials, and the effect of enhancing luminous power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment 1: The pulse laser deposition preparation method of copper-doped zinc oxide nanorods in this embodiment is carried out according to the following steps:

[0026] 1. Preparation of copper-doped zinc oxide ceramic target material: ball mill copper oxide powder with a purity of 99.9% and zinc oxide powder at a ratio of 1:(9-99) for 24 hours, pre-fire at 600-700°C for 4-8 hour, and then pressed under a pressure of 20-30MPa to form a disc with a diameter of 30-50mm and a thickness of 3mm, and then sintered at 1000-1200°C for 4-8 hours to obtain a copper-doped zinc oxide ceramic target;

[0027] 2. Clean the substrate: The substrate is ultrasonically cleaned with acetone for 5 minutes to 20 minutes, ultrasonically cleaned with deionized water for 5 minutes to 20 minutes, and ultrasonically cleaned with methanol for 5 minutes to 20 minutes. 3 cycles, that is, the cleaned substrate is obtained;

[0028] 3. Put the copper-doped zinc oxide ceramic target obta...

specific Embodiment approach 2

[0037] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the sintering is carried out at a temperature of 1050-1150° C. in step 1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0038] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 3, the distance between the substrate and the copper-doped zinc oxide ceramic target is 40-60 mm. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com