Preparation method of tritium impregnated target slice

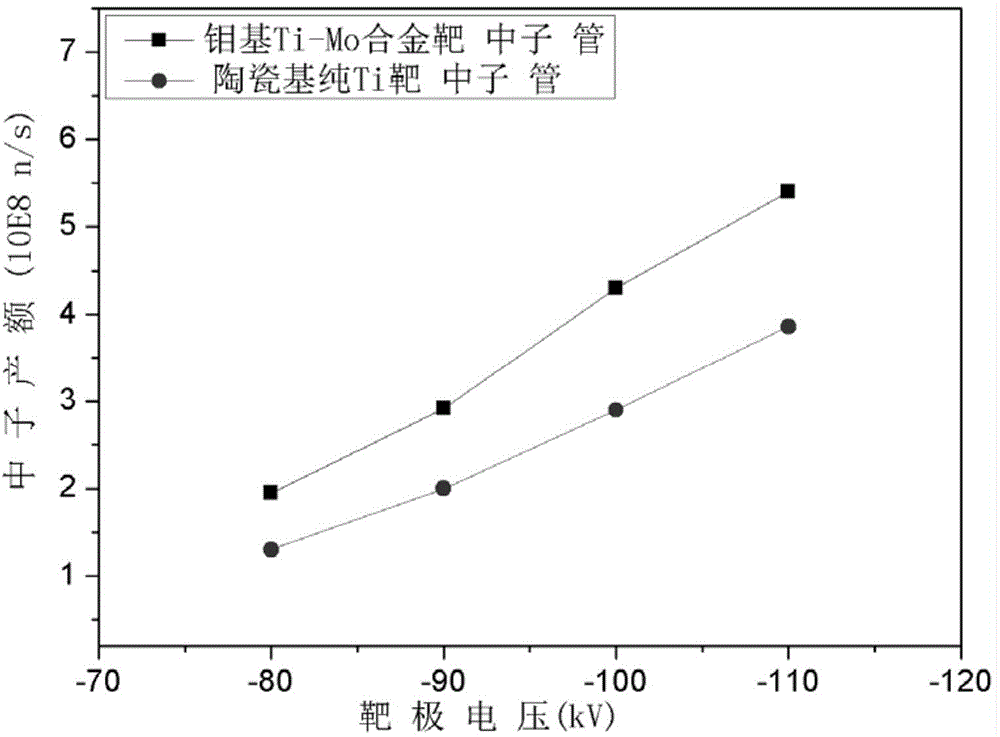

A target and wafer technology, which is applied in the field of tritium absorption target preparation, can solve the problems of reducing the tritium absorption performance of titanium film, deterioration of material mechanical properties, high-pressure breakdown of neutron tubes, etc., so as to improve the resistance to hydrogen embrittlement and oxidation. performance, increased neutron yield, and the effect of extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in further detail below.

[0026] Preparation process of molybdenum-based Ti-Mo alloy target (hereinafter referred to as target) for neutron tube: first, a high-purity molybdenum disc with a thickness of 0.5-1mm is used as the substrate material of the tritium target, and the purity is not lower than 99.99 % molybdenum disc is placed in acetone solution, ultrasonically cleaned for no less than 30 minutes to remove surface oil; secondly, the bottom of the molybdenum disc is plated with a 2-3 μm nickel film; then, the neutron tube target base is plated with An appropriate amount of silver-copper brazing filler metal is added between the molybdenum discs, and then placed in a hydrogen-burning furnace for hydrogen-burning welding; finally, the coating is performed by a high-vacuum magnetron sputtering coating process. Process parameters: First, a Ti-Mo diffusion layer of 1-1.5μm is formed between the target...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com