Synchronous flue gas desulfurization and denitrification process combining chemical absorption with anaerobic-aerobic conversion

An anaerobic, aerobic, chemical absorption technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as secondary pollution, and achieve low investment and operating costs, low energy consumption, and reasonable technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

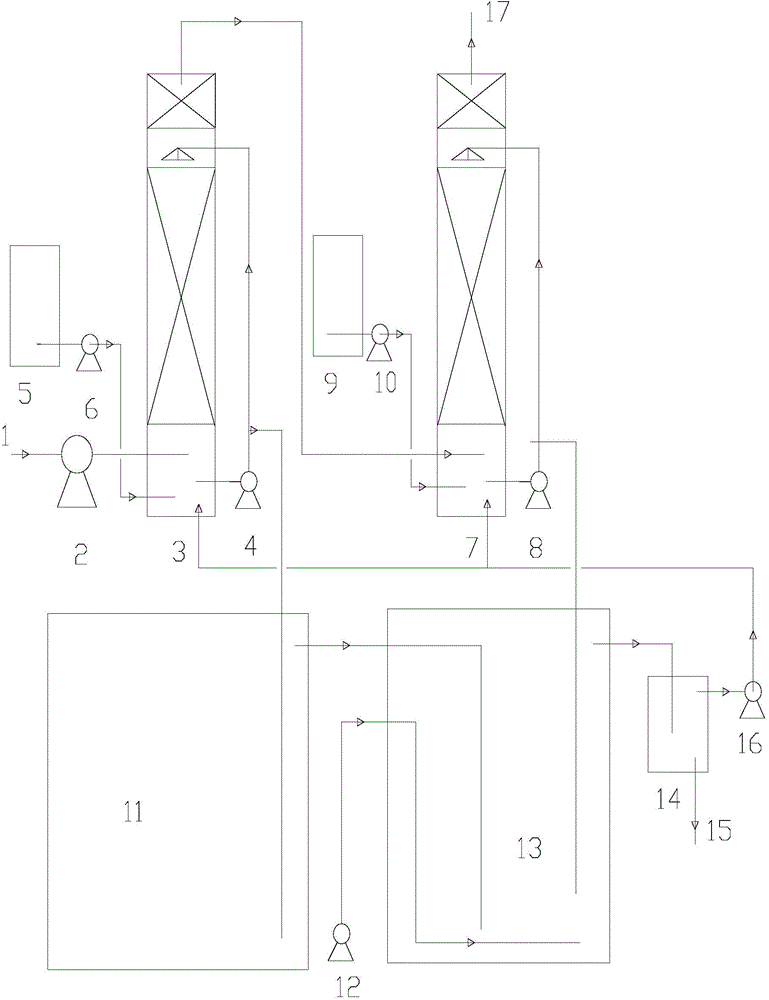

Image

Examples

Embodiment 1

[0031] An 80t / h coal-fired thermal power boiler with a flue gas flow rate of 100,000 Nm 3 / h,SO 2 The content is 1000mg / Nm 3 , NO content is 500mg / Nm 3 , the flue gas temperature is 130°C, according to the process of the present invention, when leaving the absorption tower, SO 2 The content is 50mg / Nm 3 , NO content is 100mg / Nm 3 ; The desulfurization efficiency is 95%, the denitration efficiency is 80%, the elemental sulfur recovery rate is 95%, and the recovered elemental sulfur is 1083kg / d.

[0032] SO 2 The absorption tower is a spray tower with a diameter of 3.5m, a height of 22m, and a liquid-gas ratio of 3L / Nm 3 , The desulfurization absorption liquid in the absorption process is composed of NaOH and the alkaline solution of the sulfur recovery system.

[0033] The NO absorption tower is a packed tower with a diameter of 8m, a height of 35m, and a liquid-gas ratio of 10L / Nm 3 , The denitrification absorption liquid in the absorption process is a mixture of NaClO...

Embodiment 2

[0038] A 200t / h coal-fired thermal electric boiler with a flue gas flow rate of 250,000 Nm 3 / h, SO 2 The content is 1000mg / Nm 3 , NO content is 500mg / Nm 3 , the flue gas temperature is 150°C, according to the process of the present invention, when leaving the absorption tower, SO 2 The content is 50mg / Nm 3 , NO content is 100mg / Nm 3 ; The desulfurization efficiency is 95%, the denitrification efficiency is 80%, the elemental sulfur recovery rate is 95%, and the recovered elemental sulfur is 2707kg / d.

[0039] SO 2 The absorption tower is a spray tower with a diameter of 5.6m, a height of 22m, and a liquid-gas ratio of 3L / Nm 3 , The desulfurization absorption liquid in the absorption process is composed of NaOH and the alkaline solution of the sulfur recovery system.

[0040] The NO absorption tower is a packed tower with a diameter of 13m, a height of 35m, and a liquid-gas ratio of 10L / Nm 3 , The denitrification absorption liquid in the absorption process is a mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com