Porcelain tile preparation method

A technology of porcelain bricks and adobes, which is applied in the production of clay products, ceramic materials, and other household appliances, etc., can solve the problems of failing to meet the index requirements, low flexural strength, and inability to cultivate, so as to improve the flexural strength and improve Performance index, effect of reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

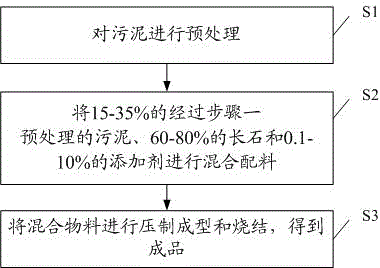

[0054] For this reason, the invention provides a kind of preparation method of porcelain tile, such as figure 1 shown, including:

[0055] S1. Pretreat the sludge.

[0056] S2. Mixing 15-35% of the sludge pretreated in step 1, 60-80% of feldspar and 0.1-10% of additives.

[0057] Preferably, the raw material formula of the porcelain tile is as follows: 15-30% of sludge pretreated in step 1, 60-75% of feldspar and 1-10% of additives.

[0058] More preferably, the raw material formula of the porcelain tile is as follows: 15-25% of sludge pretreated in step 1, 65-75% of feldspar and 3-10% of additives.

[0059] It should be noted that the additives can be selected according to the prior art.

[0060] Further, the raw material of the porcelain tile of the present invention also includes raw talc, that is, the raw material formula of the porcelain tile is: 15-35% of sludge pretreated in step 1, 60-80% of feldspar, 0.1-10% of Additives and 1-5% raw talc.

[0061] The MgO contai...

Embodiment 1

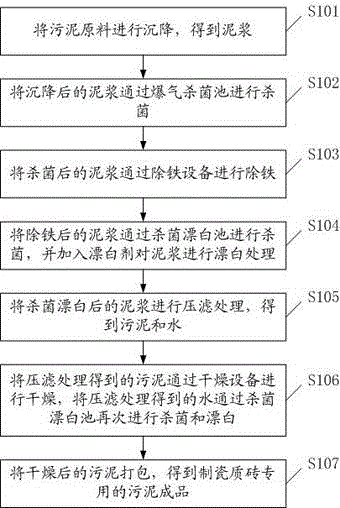

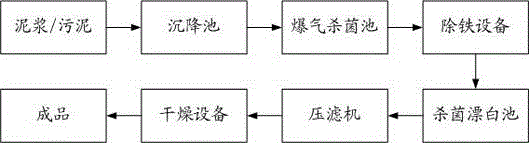

[0114] (1) Pretreatment of sludge: the sludge discharged from the sewage treatment plant is processed through two-stage sedimentation to obtain sludge; the settled sludge is sterilized through an explosion sterilization tank; the sterilized sludge is deironed by iron removal equipment iron; put the mud after iron removal into the sterilizing bleaching tank, add soda ash first, and then add sodium hydrosulfite when the pH value of the mud is 7.0, the amount of sodium hydrosulfite added is 0.5G / 100ML mud; press the mud after sterilization and bleaching Filtration treatment to obtain sludge and water; the sludge obtained by pressure filtration treatment is dried by low-temperature drying equipment at a drying temperature of 60°C, and the water obtained by pressure filtration treatment is sterilized and bleached again through a sterilizing bleaching tank; the dried The final sludge is packaged to obtain the finished sludge product.

[0115] (2) Mixing ingredients: Mix 15g of the s...

Embodiment 2

[0118] (1) Pretreatment of sludge: the sludge discharged from the sewage treatment plant is processed through two-stage sedimentation to obtain sludge; the settled sludge is sterilized through an explosion sterilization tank; the sterilized sludge is deironed by iron removal equipment iron; put the mud after iron removal into the sterilizing bleaching tank, add soda ash first, and then add sodium hydrosulfite when the pH value of the mud is 7.2, and the amount of sodium hydrosulfite added is 1.0G / 100ML mud; press the mud after sterilization and bleaching Filtration treatment to obtain sludge and water; the sludge obtained by pressure filtration treatment is dried by low-temperature drying equipment at a drying temperature of 70°C, and the water obtained by pressure filtration treatment is sterilized and bleached again through a sterilizing bleaching tank; the dried The final sludge is packaged to obtain the finished sludge product.

[0119] (2) Mixing ingredients: Mix 20g of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com