Controllable preparation method of alpha-manganese dioxide nanowire

A manganese dioxide nanometer and manganese dioxide brown technology are applied in the field of controllable preparation of α-manganese dioxide nanowires, which can solve problems such as not being obtained, and achieve product safety, simple experimental equipment requirements, and strong operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Raw materials: potassium permanganate, KMnO 4 , 99.5%; Ethanol, C 2 h 5 OH, 99.7%; distilled water.

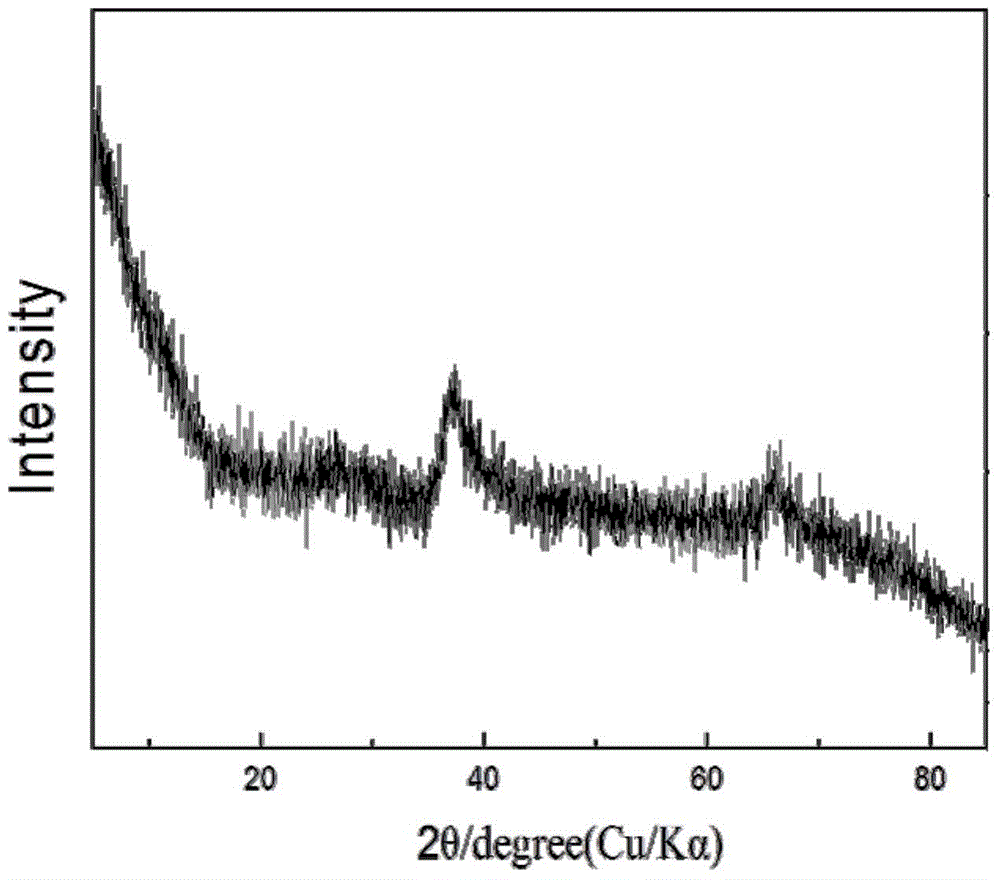

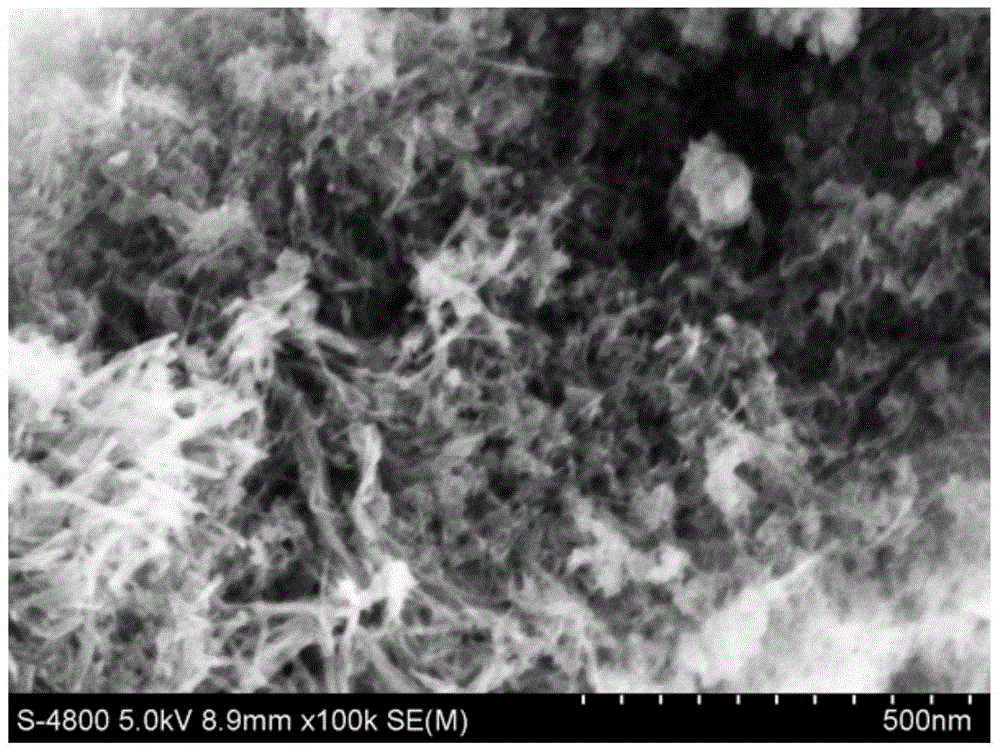

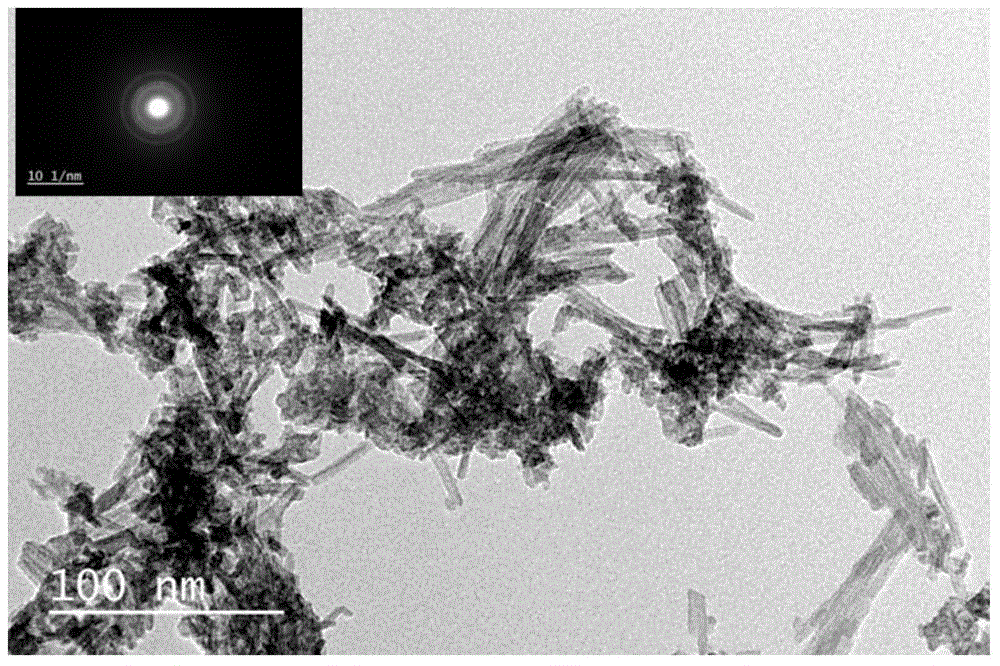

[0038] Prepare 24mL potassium permanganate aqueous solution, then add 56mL ethanol to the prepared potassium permanganate solution and mix evenly, the concentration of potassium permanganate in the mixed solution is 0.1mol / L. Then transfer the prepared mixed solution into a 100 mL Teflon-lined reaction kettle at room temperature. Close the reaction kettle, put it in an oven at 120°C for 2 hours, take it out for cooling and filtration, wash the precipitate several times and dry it to obtain α-manganese dioxide brown powder with a diameter of 10-14nm and a length of 100-140nm.

Embodiment 2

[0040] Raw materials: potassium permanganate, KMnO 4 , 99.5%; Ethanol, C 2 h 5 OH, 99.7%; distilled water.

[0041] Prepare 35mL potassium permanganate aqueous solution, then add 45mL ethanol into the prepared potassium permanganate solution and mix evenly, the concentration of potassium permanganate in the mixed solution is 0.005mol / L. Then transfer the prepared mixed solution into a 100 mL Teflon-lined reaction kettle at room temperature. Close the reaction kettle, put it in an oven at 120°C for 2 hours, take it out for cooling and filtration, wash the precipitate several times and then dry it to obtain α-manganese dioxide brown powder with a diameter of 10-12nm and a length of 100-130nm.

Embodiment 3

[0043] Raw materials: potassium permanganate, KMnO 4 , 99.5%; Ethanol, C 2 h 5 OH, 99.7%; distilled water.

[0044] Prepare 40 mL of potassium permanganate aqueous solution, and then add 40 mL of ethanol into the prepared potassium permanganate solution and mix evenly. The concentration of potassium permanganate in the mixed solution is 0.01 mol / L. Then transfer the prepared mixed solution into a 100 mL Teflon-lined reaction kettle at room temperature. Close the reaction kettle, put it in an oven at 120°C for 2 hours, take it out for cooling and filtration, wash the precipitate several times and dry it to obtain α-manganese dioxide brown powder with a diameter of 10-13nm and a length of 100-130nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com