Flame-retardant smoke inhibitor for sprayed polyurethane foam as well as preparation method and application of flame-retardant smoke inhibitor

A technology for spraying polyurethane and smoke suppressant, applied in the field of halogen-free flame retardant, can solve the problems of reducing the amount of smoke, serious migration, shortening the service life of materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

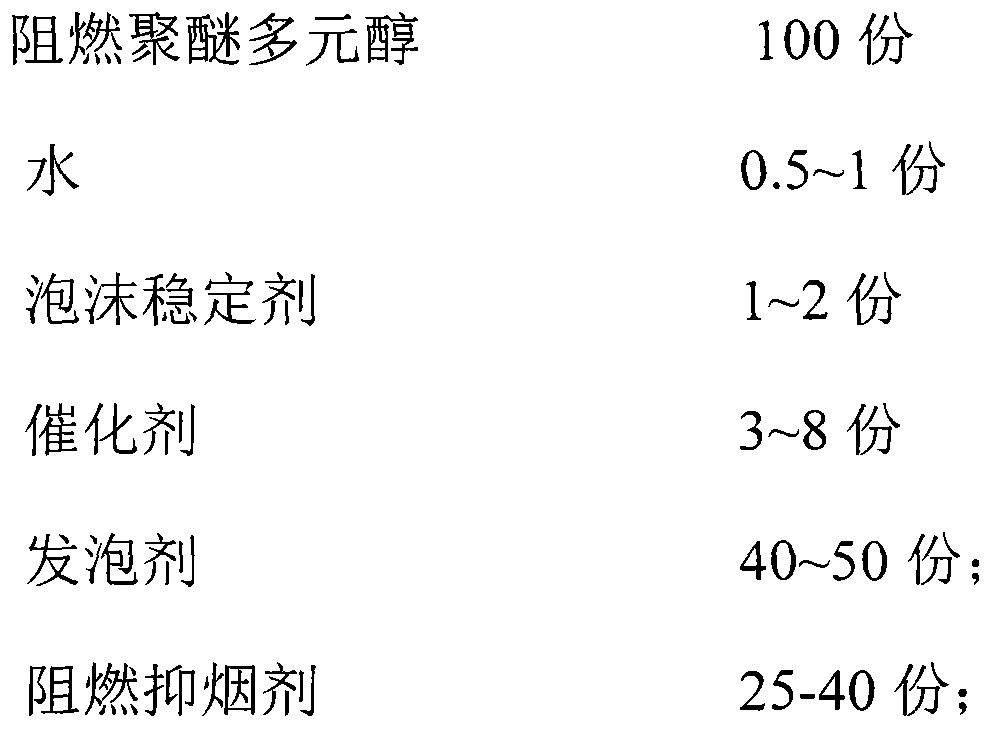

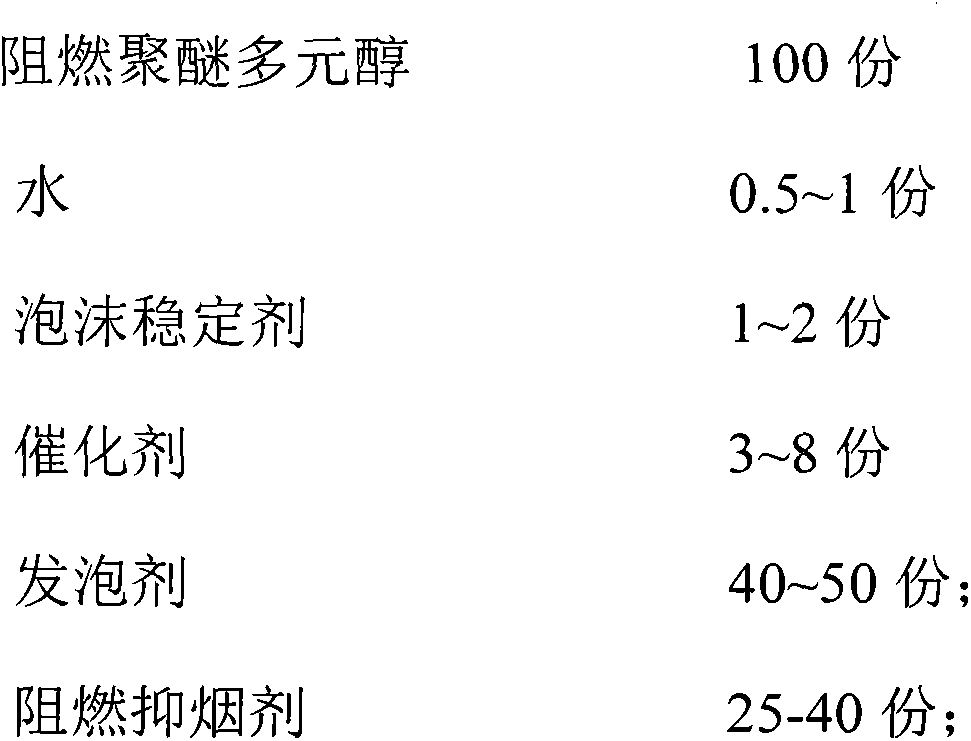

Method used

Image

Examples

Embodiment Construction

[0037] The preparation method of flame retardant and smoke suppressant for spraying:

[0038] (1) 10gCe(NO 3 ) 3 6(H 2 0) be dissolved in 1000ml deionized water, then add 100g sodium montmorillonite and 0.1mol / L sodium dodecylsulfonate solution 30ml, under stirring condition, slowly drip concentration is the ammoniacal liquor 200ml of 0.4mol / L, Make Ce(NO 3 ) 3 6(H 2 O) Completely generate white Ce(OH) 3 Precipitate, disperse and adsorb on the interlayer or surface of sodium montmorillonite, then add 1.0g of hydrogen peroxide, stir at 60°C for 30 minutes, and make Ce(OH) 3 Oxidized to reddish-brown peroxide Ce(OH) 3 OOH; then heated to 90°C for 60 minutes to make Ce(OH) 3 OOH gradually changes to yellow Ce(OH) 4 , then filter out the solid matter, wash with deionized water for 3 times, put it into a blast oven for drying, the drying temperature is 200° C., and the drying time is 2 hours, so as to obtain the sodium-based montmorillonite adsorbed with cerium hydroxide; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com