An Absorbable Antimicrobial Seaweed Fiber

A technology of seaweed fiber and sodium alginate, applied in fiber treatment, alginate artificial filament, heat treatment of artificial filament, etc., can solve the problems of cytotoxicity of antibacterial agent, complicated preparation process, and unsustainable antibacterial effect, etc. The effect of good antibacterial property and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of absorbable antibacterial seaweed fiber, its technical scheme comprises the steps:

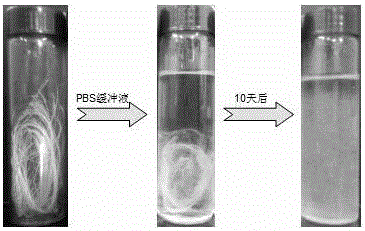

[0023] (1) Preparation of absorbable antibacterial seaweed fiber: Sodium alginate was dissolved in deionized water to obtain a sodium alginate solution with a mass percentage of 1.5% and a viscosity of 10000 mPa; a mass percentage of 4.0% calcium chloride The coagulation bath is used for conventional wet spinning at 20°C. The resulting as-spun fibers are post-stretched by 1 time, washed with water at 30°C, and then heat-treated at 100°C to obtain absorbable antibacterial seaweed fibers.

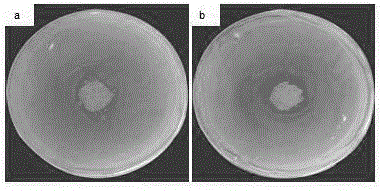

[0024] (2) Modification of absorbable antibacterial seaweed fiber: 1 g of the seaweed fiber obtained in step (1) was immersed in 200 mL of 1.0% glutaraldehyde solution by weight and cross-linked for 30 min. The breaking strength of the modified absorbable antibacterial algae fiber was 1.7 cN / dtex, and the breaking elongation was 4.5%. The antibacterial rates of the obtained seaweed fiber agai...

Embodiment 2

[0026] A kind of absorbable antibacterial seaweed fiber, its technical scheme comprises the steps:

[0027] (1) Preparation of absorbable antibacterial seaweed fiber: Dissolve sodium alginate in deionized water to obtain a 2.5% sodium alginate solution with a viscosity of 15000 mPa; 2.5% calcium chloride by mass It is a coagulation bath, and conventional wet spinning is carried out at 30°C. The resulting as-spun fibers are post-stretched 1.5 times, then washed at 40°C, and then heat-treated at 60°C to obtain absorbable antibacterial seaweed fibers.

[0028] (2) Modification of absorbable antibacterial seaweed fiber: 1 g of the seaweed fiber obtained in step (1) was immersed in 500 mL of 1.0% glutaraldehyde solution by weight and cross-linked for 60 min. The breaking strength of the modified absorbable antibacterial algae fiber was 2.0 cN / dtex, and the breaking elongation was 5.0%. The antibacterial rates of the obtained seaweed fiber against Staphylococcus aureus and Escheric...

Embodiment 3

[0030] A kind of absorbable antibacterial seaweed fiber, its technical scheme comprises the steps:

[0031] (1) Preparation of absorbable antibacterial seaweed fiber: Sodium alginate was dissolved in deionized water to obtain a 3.5% sodium alginate solution with a viscosity of 20,000 mPa; 1.5% calcium chloride by mass It is a coagulation bath, and conventional wet spinning is carried out at 55°C. The obtained as-spun fibers are post-stretched twice, then washed at 50°C, and then heat-treated at 60°C to obtain absorbable antibacterial seaweed fibers.

[0032] (2) Modification of absorbable antibacterial seaweed fiber: 1 g of the seaweed fiber obtained in step (1) was immersed in 1000 mL of 1.0% glutaraldehyde solution by weight and cross-linked for 120 min. The breaking strength of the modified absorbable antibacterial algae fiber was 1.9 cN / dtex, and the breaking elongation was 4.0%. The antibacterial rates of the obtained seaweed fiber against Staphylococcus aureus and Esche...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com