PMMA-SnO2-based thin-film gas sensor for detecting methane

A technology of gas sensor and thin film, which is applied in the field of preparation of PMMA-SnO2 based thin film structure, can solve the problems of increased energy consumption, decreased stability, and high working temperature of gas sensor, and achieves low cost, good conductivity, and The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

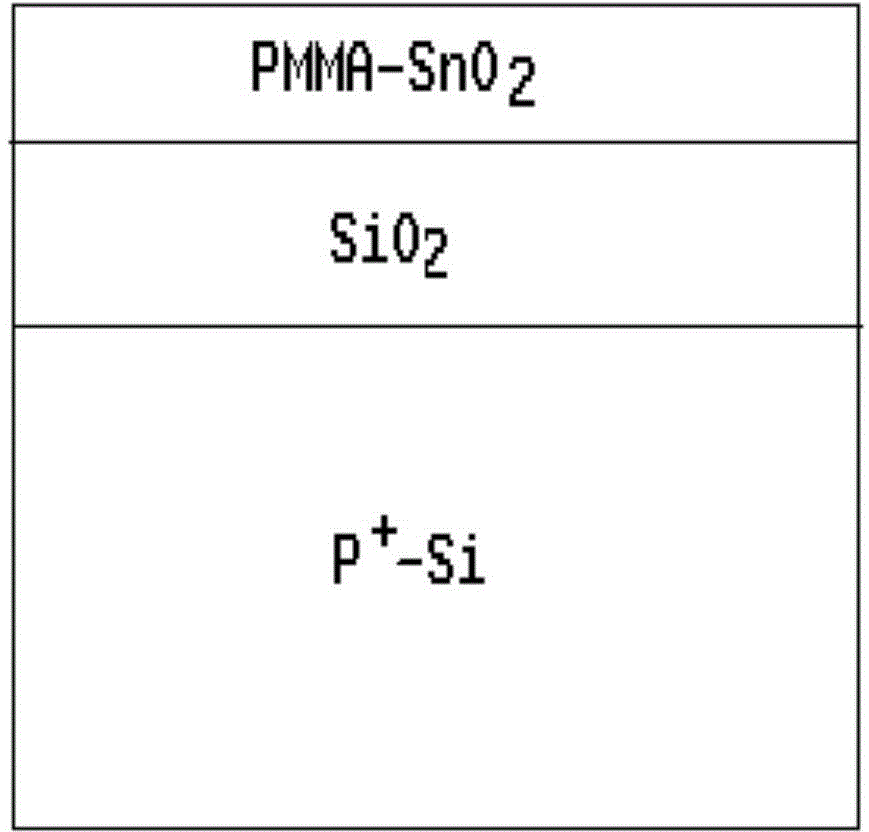

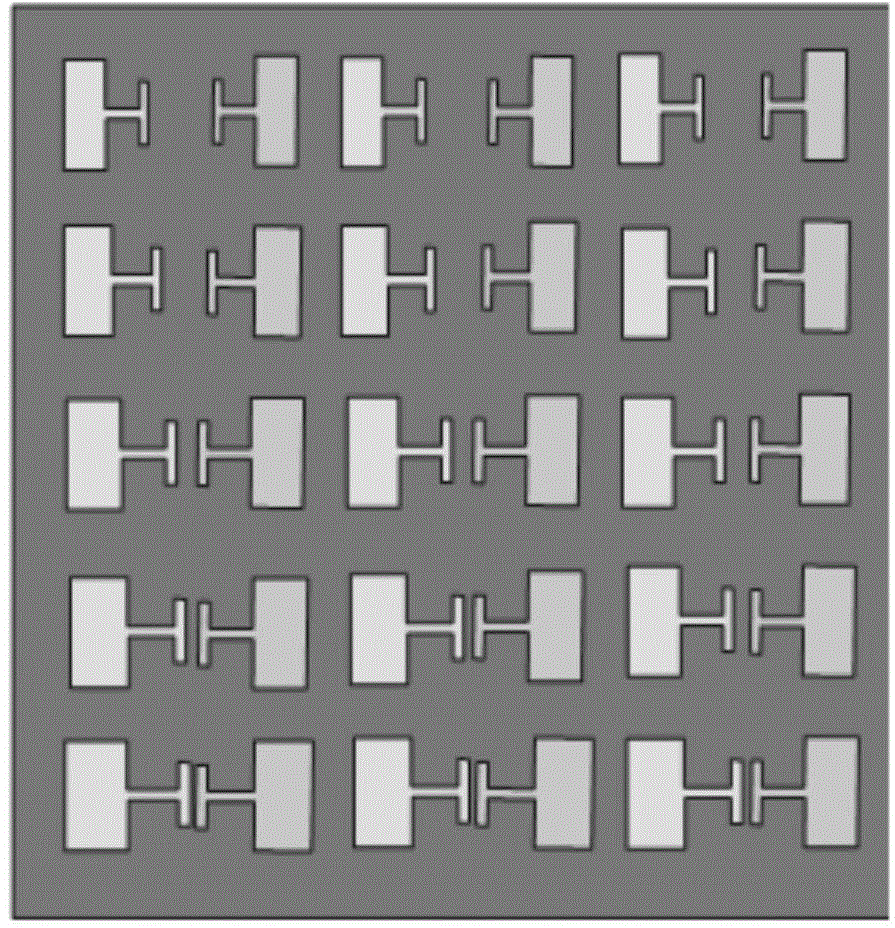

[0029] In order to make the present invention clearer, below in conjunction with specific embodiment, and with reference to appended figure 1 , 2, the present invention is further described in detail.

[0030] It adopts a relatively simple process method, that is, a kind of sol-gel method (sol-gel) in the wet preparation method----spin coating. PMMA dissolved in chloroform is used to increase the adhesion of SnO2 nanocrystals to the substrate and improve the quality of the film; n-butylamine is used to prevent the aggregation of SnO2 nanoparticles and to make the gas to be measured more easily attached to the surface of the film. The viscosity of PMMA will neither cover the quantum dots nor cause the film to fall off from the substrate.

[0031] The substrate on which the thin film is attached can be a silicon wafer with an SiO2 oxide layer, a quartz wafer, a glass wafer, or even a polymer material.

[0032] The solvent of PMMA in the film can be chloroform, anisole, aceton...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com