Manufacturing method of large-capacity capacitor, capacitor battery, and battery assembly

A capacitor and large-capacity technology, applied in the direction of fixed capacitor electrodes, fixed capacitor components, fixed capacitor dielectrics, etc., can solve the problems of low withstand voltage, long charging time, complex structure, etc., and achieve high withstand voltage and increased specific surface area. , the effect of increasing the capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

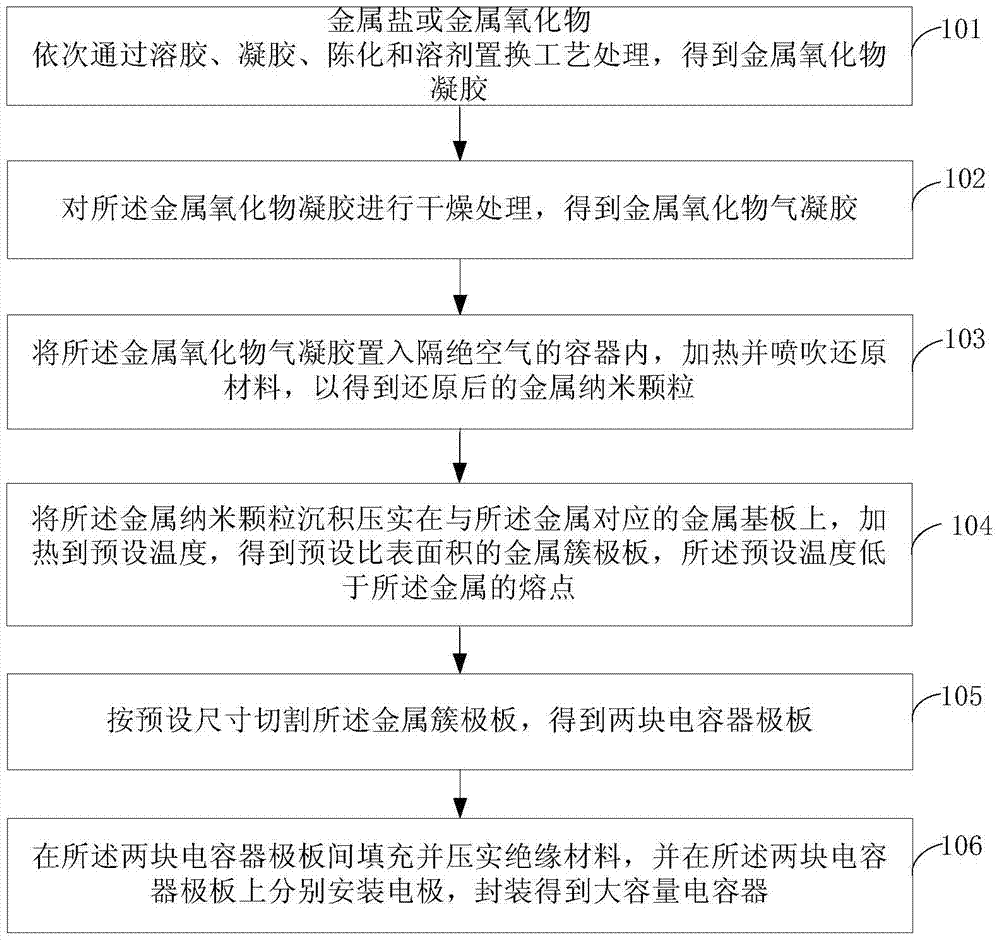

[0034] figure 1 The flow chart of the manufacturing method of the large-capacity capacitor provided for the embodiment of the present invention, as figure 1 As shown, the method includes:

[0035] Step 101, the metal salt or metal oxide is sequentially processed through sol, gel, aging and solvent replacement processes to obtain a metal oxide gel;

[0036] The metal salt in this embodiment, for example, can be copper chloride, copper sulfate, etc., copper chloride or copper sulfate is catalyzed by water and organic solvents such as ethanol, n-hexane or n-heptane, according to Add a certain proportion of polyacrylic acid to mix and stir evenly, then add propylene oxide and stir evenly, let stand for a while and wait for gelation. For example, dissolve copper chloride in ethanol, such as copper chloride in 10% weight concentration ethanol solution, add 30% weight deionized water and mix evenly, then add 15% polyacrylic acid and stir for 0.5-1 Hours, after stirring evenly, slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com