Additive for improving early strength of cement based material as well as preparation method and application of additive

A cement-based material and early-strength technology, applied in the field of concrete admixtures, can solve problems such as limited early-strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

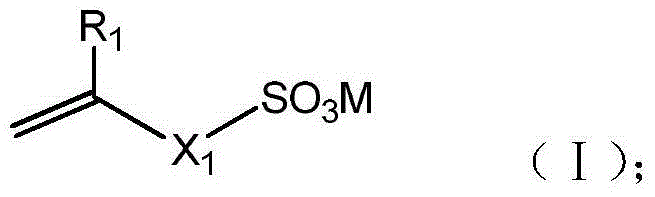

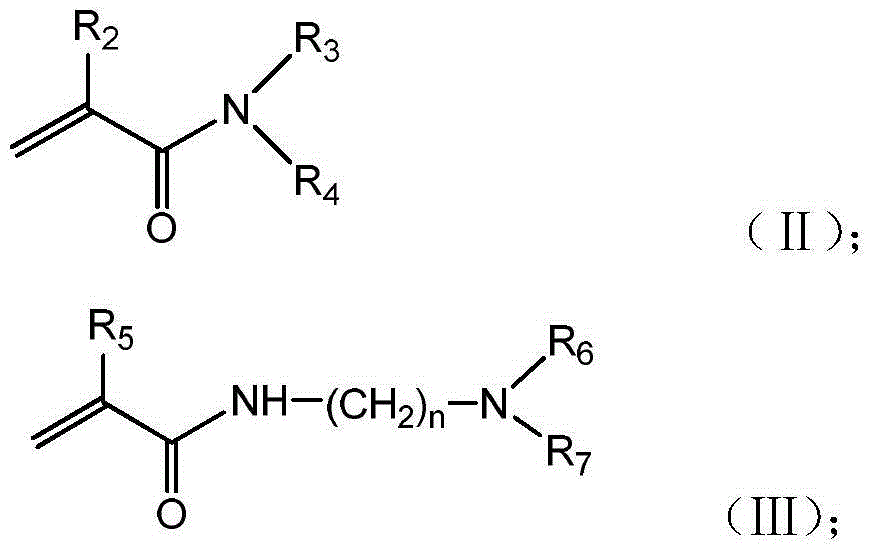

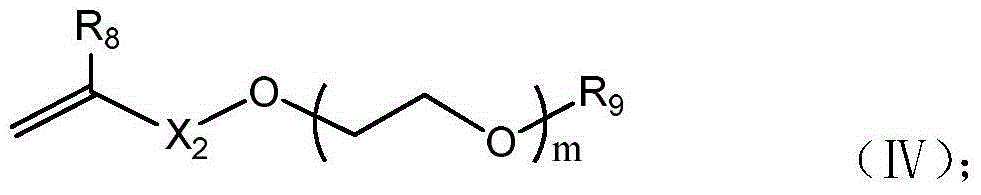

Method used

Image

Examples

Embodiment 1

[0051] Add 40g of distilled water, 62.3g of polyether macromonomer c-1 and 5.37g of 30% hydrogen peroxide into a 2L glass round-bottomed flask equipped with a thermometer, a stirrer, a dropping funnel and a nitrogen conduit, and stir to raise the temperature dissolve. Under nitrogen protection, the temperature in the flask was maintained to 5°C, and then 8.22g monomer a-1, 9.22g monomer b-1, 0.41g 3-mercaptopropionic acid, 0.34g sodium formaldehyde sulfoxylate and 80g Distilled water was mixed and stirred to make a uniform monomer aqueous solution, which was added dropwise to a round bottom flask at a constant speed for 1 hour; at the same time, 0.92 g of monomer d-1 was added dropwise at a constant speed for 1 hour. , to maintain the pH of the system at 6-7. After the aqueous monomer solution is added dropwise, M w = 50345 ionic polymer, then add 1411.5g of distilled water at 60°C to the flask at one time, raise the temperature to 60°C, then add 282.3g of triethoxysilane dr...

Embodiment 2

[0053]Into a 2L glass round-bottomed flask equipped with a thermometer, a stirrer, a dropping funnel and a nitrogen gas conduit, add 20 g of distilled water and 92.6 g of polyether macromonomer c-2, stir and heat up to dissolve. Under the protection of nitrogen, the temperature in the flask was maintained to 35°C, and then 29.26g of monomer a-2, 0.95g of monomer b-2, 0.14g of thioglycolic acid, 0.51g of sodium bisulfite and 30g of distilled water were mixed and stirred to prepare Uniform monomer aqueous solution, drop it into the round bottom flask at a constant speed, the dropping time is 0.5h; add 3.45g monomer d-2 dropwise at a constant speed, the dropping time is 0.5h; Sodium sulfate and 34g of distilled water are mixed to form an aqueous initiator solution, and the dropwise addition time is 40 minutes. During the dropwise addition, the pH value of the system is maintained at 6-7. After the aqueous solution of the initiator is added dropwise, M is obtained w = 76408 ionic...

Embodiment 3

[0055] Into a 2L glass round-bottomed flask equipped with a thermometer, a stirrer, a dropping funnel and a nitrogen gas conduit, add 37g of distilled water and 84.2g of polyether macromonomer c-3, stir and heat up to dissolve. Under the protection of nitrogen, the temperature in the flask was maintained to 20°C, and then 37.35g of monomer a-3, 3.26g of monomer b-3, 1.10g of 2-mercaptopropionic acid, 2.86g of sodium sulfite and 50g of distilled water were mixed and stirred to prepare Uniform monomer aqueous solution, drop it into the round bottom flask at a constant speed, the dropping time is 2h; add 3.07g monomer d-3 dropwise at a constant speed, the dropping time is 2h; at the same time add 1.02g potassium persulfate The initiator aqueous solution mixed with 40g of distilled water is added dropwise for 125 minutes, and the pH of the system is maintained at 6-7 during the dropwise addition. After the aqueous solution of the initiator is added dropwise, M is obtained w = 798...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com