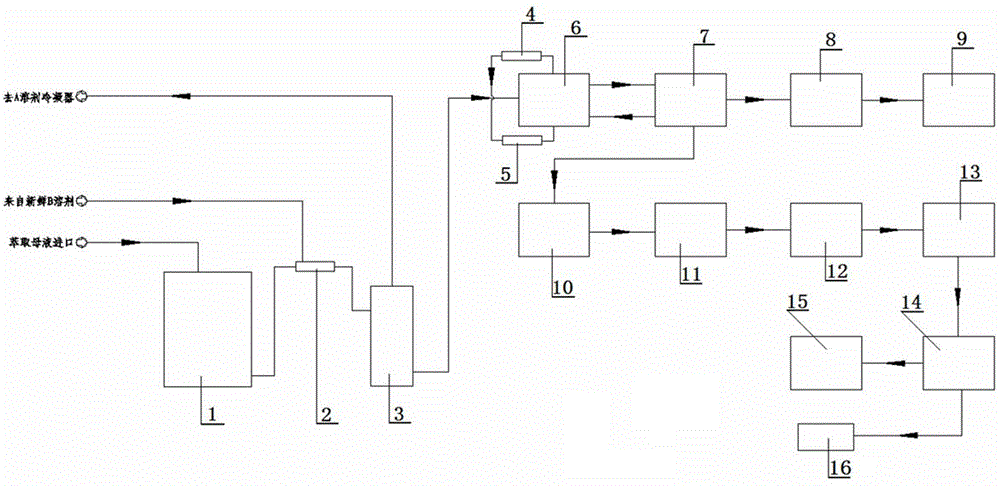

Method and device for producing 2-naphthol and coproducing 2,3 acid by solvent method continuous carbonization

A solvent method and naphthol technology, which is applied in the field of synthesis and production of 2-hydroxy-3-naphthoic acid, can solve the problems of affecting product export competitiveness, large environmental impact, difficult and high-salt organic wastewater, etc., and achieve product purity and appearance. Color improvement, good economic benefits and environmental effects, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Add the hydrogenated terphenyl and β-naphthol sodium into the ethanol solvent extraction concentrate from the extraction section in a mass ratio of 1.5:1 for mixing; after mixing evenly, enter the de-A rectification tower to remove the ethanol solvent; remove The material after the ethanol solvent enters the carbonization reactor and CO 2 Reaction, the reacted material enters the 2-naphthol crude product distillation tower to remove the 2-naphthol crude product and then enters the carbonization reactor and CO 2 Reaction: The content of sodium β-naphthol in the tower bottom material after continuous carbonization for 4 hours at a pressure of 0.7 MPa was 36.2%, and that of 2-naphthol was 0.5%. The 2-naphthol crude product at the top of the tower is sent to the rectification tower for continuous rectification to obtain qualified 2-naphthol products, which are sliced and packaged by a slicing and packaging device for sale; the bottom materials are statically separated, an...

Embodiment 2

[0058] Add the hydrogenated terphenyl and β-naphthol sodium into the methanol solvent extraction concentrate from the extraction section in a mass ratio of 1.5:1 for mixing; after mixing evenly, enter the de-A rectification tower to remove the methanol solvent; remove The material after the methanol solvent enters the carbonization reactor and CO 2 Reaction, the reacted material enters the 2-naphthol crude product 2-naphthol crude product distillation tower and removes the 2-naphthol crude product and then enters the carbonization reactor and CO 2 Reaction: The content of β-naphthol sodium in the tower bottom material after the pressure is 0.7 MPa and continuous carbonization for 8 hours is 7.6%, and the content of 2-naphthol is 0.43%. The crude product at the top of the tower is sent to the 2-naphthol finished product rectification tower for continuous rectification to obtain qualified 2-naphthol products, which are sold after being sliced and packaged by a slicing and pack...

Embodiment 3

[0060] Add 70% of 1-methyl-3-phenylindane + 30% of 12-alkylbenzene mixed solvent (referred to as B solvent) and β-naphthol sodium in a mass ratio of 2.0:1 to the extraction The n-propanol solvent extraction concentrate in the workshop section is mixed; after mixing evenly, it enters the de-A rectification tower to remove the n-propanol solvent; the material after removing the n-propanol solvent enters the carbonization reactor and CO 2 Reaction, after the reacted material enters the 2-naphthol crude product distillation tower to remove the 2-naphthol crude product, it enters the carbonization reactor and CO 2 Reaction: The content of β-naphthol sodium in the tower bottom material after the pressure is 0.8MPa and continuous carbonization for 10h is 4.6%, 0.55%. The crude product at the top of the tower is sent to the 2-naphthol finished product rectification tower for continuous rectification to obtain qualified 2-naphthol products, which are sold after being sliced and packa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com