Fluorene derivative containing carbazole-9-yl group and application thereof

A technology of fluorene derivatives and groups, applied in the field of new organic compounds, can solve problems such as low glass transition temperature, no bright spots, and shortened device life, and achieve simple preparation process, improved service life, and good thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

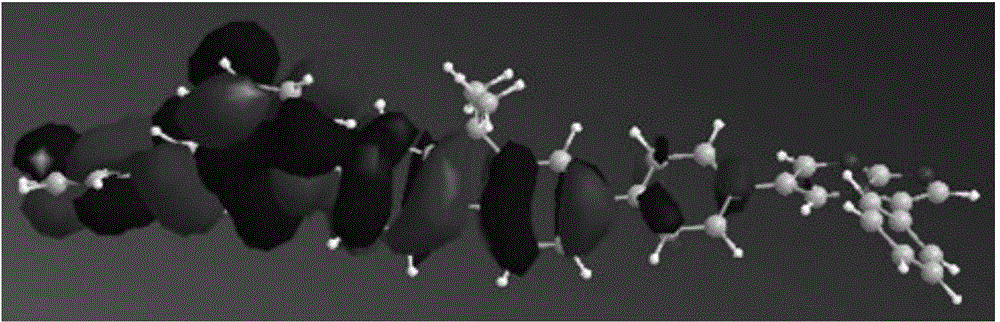

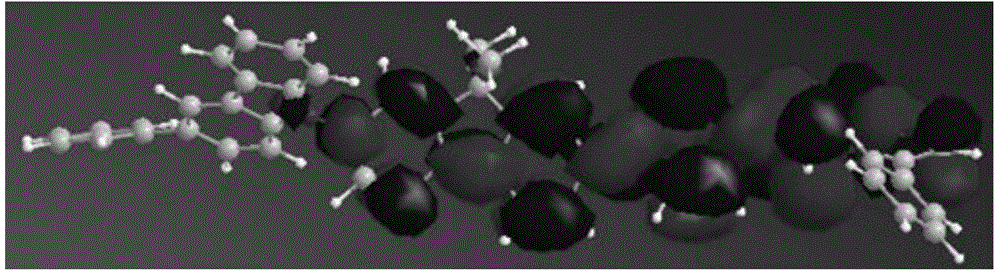

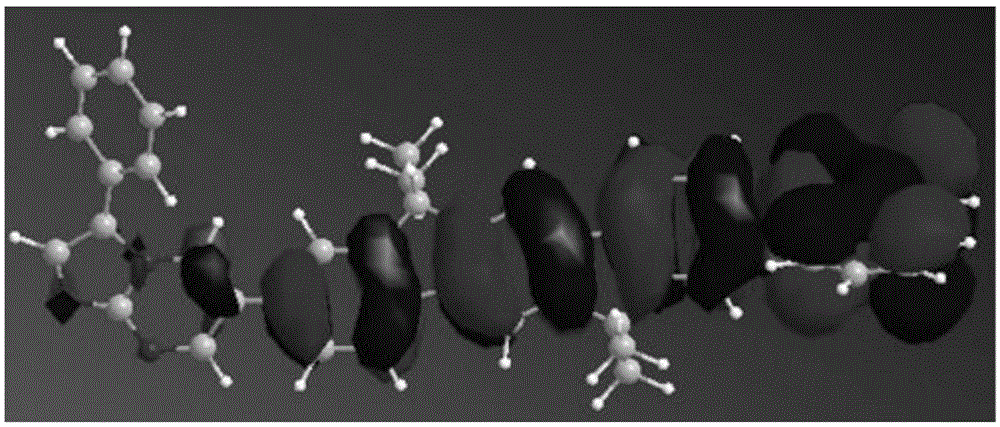

Image

Examples

Embodiment 1

[0048] Synthesis of compound 1

[0049] first step,

[0050]

[0051] In a 500ml three-neck flask equipped with electric stirring and protected by Ar gas, add 16.7g of carbazole (molecular weight 167, 0.10mol), 44g of 2-bromo-7-iodo-9,9-dimethylfluorene (molecular weight 398 , 0.11mol), cuprous iodide 1.9g (molecular weight 190, 0.01mol), potassium carbonate 28g (molecular weight 138, 0.203mol), 18-crown-6 1.2g (molecular weight 264, 0.00455mol), adding solvent DMPU 250ml. Stir at reflux for 4 hours and monitor the reaction by TLC. After the reaction is complete, naturally stir to lower the temperature to below 80°C, then add 500ml of water and stir, a light yellow solid product is precipitated, filtered out, and dried in the air. It was separated by silica gel column chromatography to obtain 35.7 g of a slightly yellow product with a molecular weight of 437, a purity of 98.0%, and a yield of 80.2%.

[0052] second step,

[0053]

[0054] In a 500 ml three-necked fl...

Embodiment 2

[0066] Synthesis of compound 2

[0067]

[0068] The synthesis process is divided into three steps. The first step is the same as the first step reaction in Example 1, except that the carbazole is replaced with 3-phenylcarbazole as a raw material, and other raw materials and processes are unchanged to obtain a corresponding Bromine intermediate; the second step is the same as the second step in Example 1, except that 2-bromo-7-(carbazol-9 base)-9,9-dimethylfluorene is synthesized by the first step here The bromine intermediate is replaced as a raw material, and other raw materials and processes are unchanged to obtain the corresponding boronic acid derivative; the third step is the same as the fifth step reaction in Example 1, except that the 7-(carbazol-9-yl) -9,9-Dimethylfluorene-2-boronic acid was replaced by the boronic acid derivative synthesized in the second step here as the raw material, and the other raw materials and processes remained unchanged to obtain compound...

Embodiment 3

[0071] Synthesis of compound 3

[0072]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com