Method for testing content of galactooligosaccharide in formula milk powder

A technology of galacto-oligosaccharide and formula milk powder, which is applied in the directions of measuring devices, instruments, scientific instruments, etc., to achieve the effect of simple operation and good extraction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

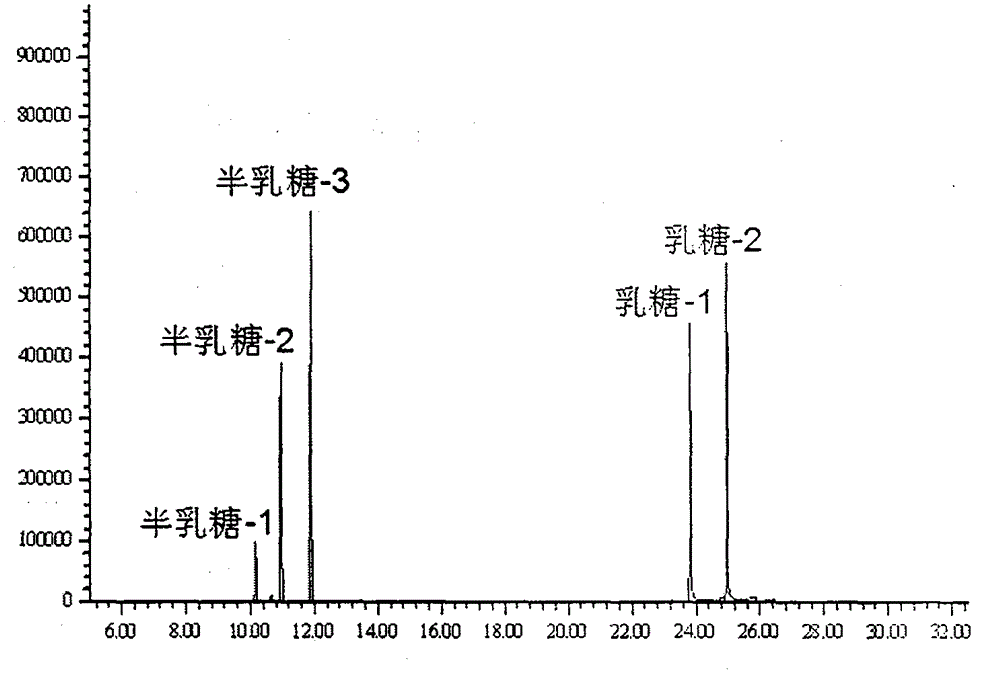

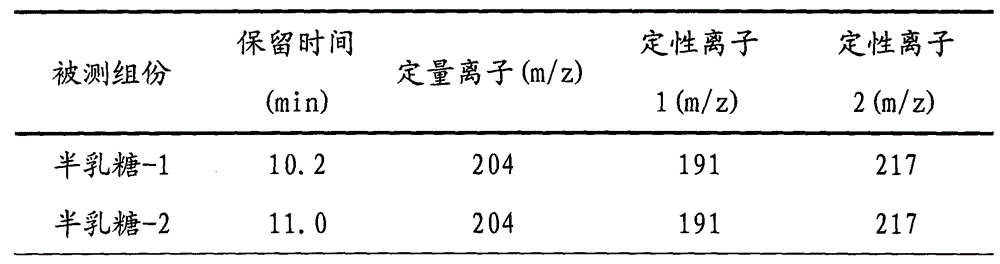

[0065] Embodiment 1 Gas chromatography-mass spectrometry determination of galacto-oligosaccharide content in infant formula milk powder

[0066] (1) Extraction: Weigh 1.0g of the sample (accurate to 0.0001g) into a 50mL graduated plastic centrifuge tube, add 40mL of phosphate buffer solution (0.2M phosphate buffer: 22.0g of potassium dihydrogen phosphate + 6.0g of dihydrogen phosphate Potassium + 1.0L secondary water) dissolved, vortexed to mix. Shake continuously in a water bath at 80°C±2°C for 30min, and after cooling to room temperature, dilute to 100mL with phosphate buffer solution. Pipette 5.0mL of sample extraction solution into a 50mL volumetric flask, dilute to 50mL with phosphate buffer solution, and set aside.

[0067] (2) Enzymolysis: Pipette 1.0mL of the extract into a 10mL volumetric flask at the same time, add 0.5mL of β-galactosidase solution (50U / mL), mix well, keep shaking in a water bath at 50°C±2 for 60min, and cool to After room temperature, dilute to 10...

Embodiment 2

[0084] Example 2 Gas chromatography-mass spectrometry determination of galactooligosaccharides in the second stage of infant formula goat milk powder

[0085] (1) Sample extraction: Weigh 1.0003g and 1.0010g of the second stage of infant formula goat milk powder respectively, add 40mL phosphate buffer solution to a 100mL volumetric flask to dissolve, and vortex to mix. Shake continuously in a water bath at 80°C±2°C for 30min, and after cooling to room temperature, dilute to 100mL with phosphate buffer solution. Pipette 5.0mL of sample extraction solution into a 50mL volumetric flask, dilute to 50mL with phosphate buffer solution, and set aside.

[0086] (3) Enzymolysis: Pipette 1.0mL of the extract into a 10mL volumetric flask, add 0.5mL of β-galactosidase solution (50U / mL), mix well, keep shaking in a water bath at 50°C for 60min, cool to room temperature and use Dilute to 10 mL with 20% acetonitrile, shake well, centrifuge at 10,000 r / min for 10 min, filter the upper aqueou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionization energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com