High-light-sensitivity photoresist composition taking melamine and anacardol modified phenolic resin as matrix

A technology of phenolic resin and melamine, which is applied in the direction of optics, photomechanical equipment, photoplate making process of pattern surface, etc., can solve the problems of photoresist photosensitive performance decline and affect production efficiency, etc., to improve heat resistance and high photosensitivity Performance, improvement of toughness and heat resistance, effect of photosensitive improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Synthesis of phenolic resin modified with melamine and cardanol: Add 30 g of 38% formaldehyde solution, 36 g of phenol, and 4.2 g of oxalic acid into a three-necked flask equipped with a reflux condensation stirring thermometer device, and stir evenly. After stirring evenly, add 15.6 g of melamine and 22.2 g of cardanol into the three-necked flask, pass nitrogen gas into the flask to remove oxygen, seal it, and stir under reflux for 1.5 hours in an oil bath at 110°C. Open the three-necked flask, then add 3.4g of 25% HCl hydrochloric acid solution, pass nitrogen into the flask to remove oxygen, seal it, reflux and stir, react in an oil bath at 120°C for 12 hours, then lower the temperature and cool down, filter and dry to obtain a modified phenolic resin.

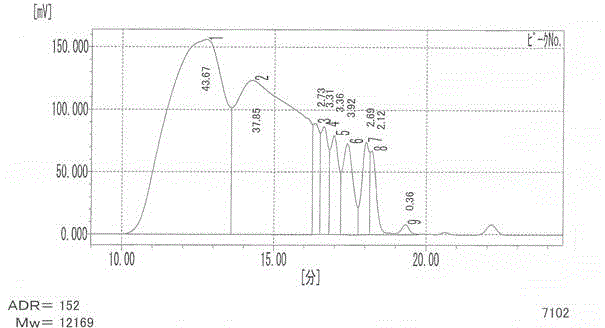

[0033] figure 1 It is the gel chromatogram of the modified phenolic resin, the weight average molecular weight is 12169, the alkali dissolution rate is 152A / S, and the softening point temperature is 169°C.

[0034] T...

Embodiment 2

[0037] Synthesis of phenolic resin modified with melamine and cardanol: Add 30 g of 38% formaldehyde solution, 36 g of phenol, and 4.2 g of oxalic acid into a three-necked flask equipped with a reflux condensation stirring thermometer device, and stir evenly. After stirring evenly, add 14.3g of melamine and 23.9g of cardanol into the three-necked flask, pass nitrogen gas into the flask to remove oxygen, seal it, reflux and stir in an oil bath at 110°C for 1.5 hours. Open the three-necked flask, then add 3.4g of 25% HCl hydrochloric acid solution, pass nitrogen into the flask to remove oxygen, seal it, reflux and stir, react in an oil bath at 120°C for 12 hours, then lower the temperature and cool down, filter and dry to obtain a modified phenolic resin.

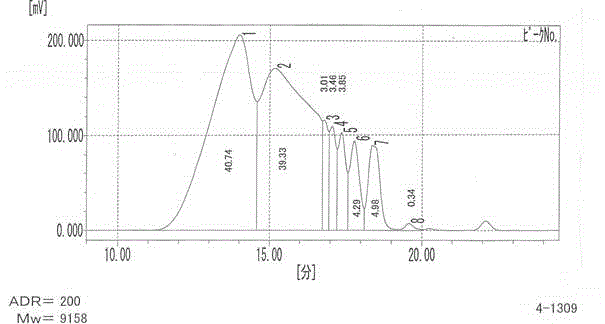

[0038] figure 2 It is the gel chromatogram of the modified phenolic resin, the weight average molecular weight is 9158, the alkali dissolution rate is 200A / S, and the softening point temperature is 167°C.

[0039] The prepa...

Embodiment 3

[0042] Synthesis of Phenolic Resin Modified with Melamine and Cardanol: Stirring Thermometer Equipped with Reflux Condensation

[0043]Add 30g of 38% formaldehyde solution, 36g of phenol, and 4.2g of oxalic acid into the three-necked flask of the device, and stir evenly. After stirring evenly, add 16.2g of melamine and 21.3g of cardanol into the three-necked flask, pass nitrogen into the flask to remove oxygen, seal it, and stir under reflux for 1.5 hours in an oil bath at 110°C. Open the three-necked flask, then add 3.4g of 25% HCl hydrochloric acid solution, pass nitrogen into the flask to remove oxygen, seal it, reflux and stir, react in an oil bath at 120°C for 12 hours, cool down, filter and dry to obtain a modified phenolic resin.

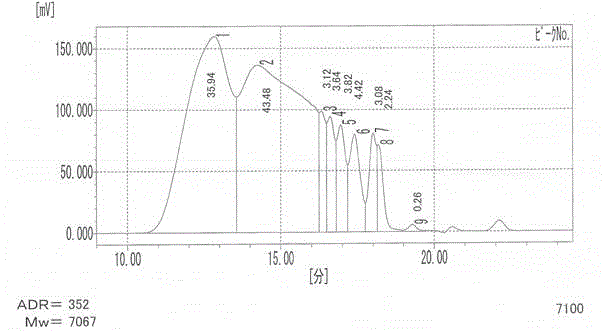

[0044] image 3 It is the gel chromatogram of the modified phenolic resin, the weight average molecular weight is 7067, the alkali dissolution rate is 352A / S, and the softening point temperature is 162°C.

[0045] The preparation of the pho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com