Stainless non-woven fabric based super-capacitor electrode material as well as preparation method and application

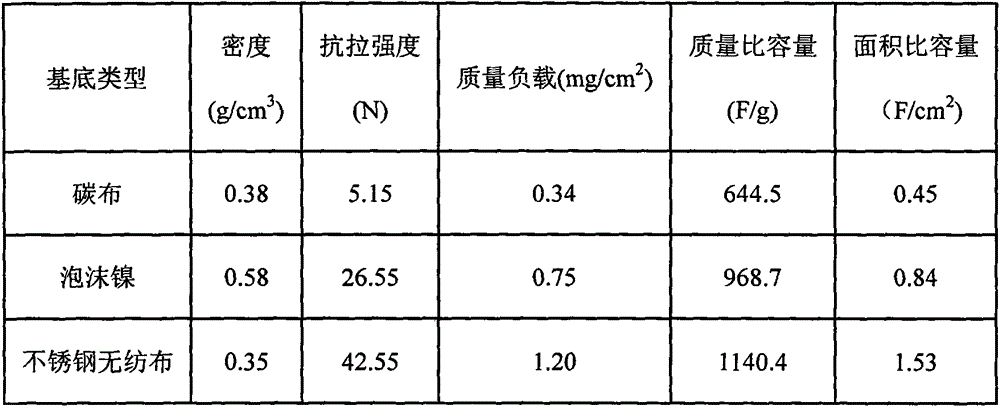

A supercapacitor, non-woven-based technology, used in the manufacture of hybrid capacitor electrodes, hybrid capacitor current collectors, and hybrid/electric double-layer capacitors, can solve the problems of lack of flexibility, poor mechanical strength, incompatibility, etc. Good specific surface area and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] Embodiment 1: In this embodiment, the preparation method of the stainless steel non-woven fabric-based electrode material with nanostructure grown by hydrothermal method is implemented according to the following steps:

[0027] 1. Cut the stainless steel non-woven fabric into 1×3cm 2 Put it into a 100mL beaker, then add acetone until the non-woven fabric is covered, ultrasonically treat for about 7min, and then ultrasonically treat with dilute hydrochloric acid for 7min. Rinse with deionized water repeatedly, and then sonicate with absolute ethanol for 7 minutes. Put into 80 ℃ forced air drying oven to dry.

[0028] 2. Preparation of hydrothermal growth nanostructure solution: 0.65gNi(NO 3 ) 2 , 1.3gCo(NO 3 ) 2 , 1.62g urea, 45mL deionized water, 45mL absolute ethanol.

[0029] 3. Put the reaction solution into a polytetrafluoroethylene-lined reaction kettle, and immerse the dried stainless steel non-woven fabric in the solution.

[0030] 4. Tighten the reaction ...

specific Embodiment approach 2

[0032] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the solution (5mmol Co(NO 3 ) 2 , 10 mmol NH 4 F, 25mmol Co(NH 2 )2 , 70mL H 2 O). Other steps and parameters are the same as those in Embodiment 1. That is, the growth of Co 3 o 4 Nanostructured stainless steel nonwoven-based electrode materials.

specific Embodiment approach 3

[0033] Embodiment 3: This embodiment is different from Embodiment 2 in that argon protection is added during heat treatment. Other steps and parameters are the same as in the second embodiment. A stainless steel non-woven fabric-based electrode material grown with CoO nanostructures was obtained. The effect of adding argon protection in this embodiment is to keep the Co 2+ Not oxidized by oxygen at high temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com