Permanent magnets, electric motors and generators

A permanent magnet and atomic technology, applied in the direction of magnetic objects, electric components, magnetic circuit rotating parts, etc., can solve the problem of reducing the squareness ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

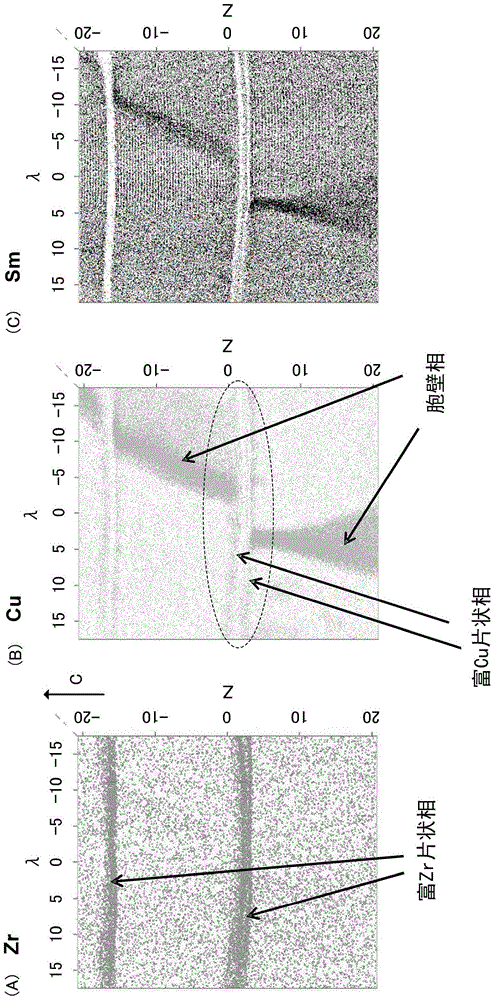

[0017] Hereinafter, the permanent magnet of this embodiment is demonstrated.

[0018]

[0019] The permanent magnet of the present embodiment has the composition represented by the following composition formula: R p Fe q m r Cu t co 100-p-q-r-t

[0020] (wherein, R is at least one element selected from rare earth elements, M is at least one element selected from Zr, Ti, and Hf, p is a number satisfying 10.5≦p≦12.5 atomic %, q In order to satisfy the number of 23≦q≦40 atomic %, r is the number satisfying 0.88≦r≦4.5 atomic %, and t is the number satisfying 4.5≦t≦10.7 atomic %)

[0021] R in the composition formula is an element that can make the magnet material have greater magnetic anisotropy. For example, one or more elements can be selected from rare earth elements containing yttrium (Y) as R elements, such as samarium (Sm), cerium (Ce), neodymium (Nd), and praseodymium (Pr), etc. can be used, Particular preference is given to using Sm. For example, when a plurality...

no. 2 Embodiment approach

[0076] The permanent magnet of the first embodiment can be used in various electric motors and generators. In addition, it can also be used as a fixed magnet or a variable magnet of a variable flux motor or a variable flux motor. By using the permanent magnet of the first embodiment, various motors and generators are configured. When the permanent magnet of the first embodiment is applied to a variable flux motor, it is also possible to use Japanese Patent Laid-Open No. 2008-29148 or Japanese Patent Laid-Open No. 2008-43172 in the configuration or drive system of the variable flux motor. technology disclosed in the bulletin.

[0077] Next, a generator and a motor according to the embodiment will be described with reference to the drawings. Figure 4 It is a figure which shows the permanent magnet motor in this embodiment. exist Figure 4 In the shown permanent magnet motor 1 , a rotor 3 is arranged inside a stator 2 . The permanent magnet 5 which is the permanent magnet o...

Embodiment 1、 Embodiment 2

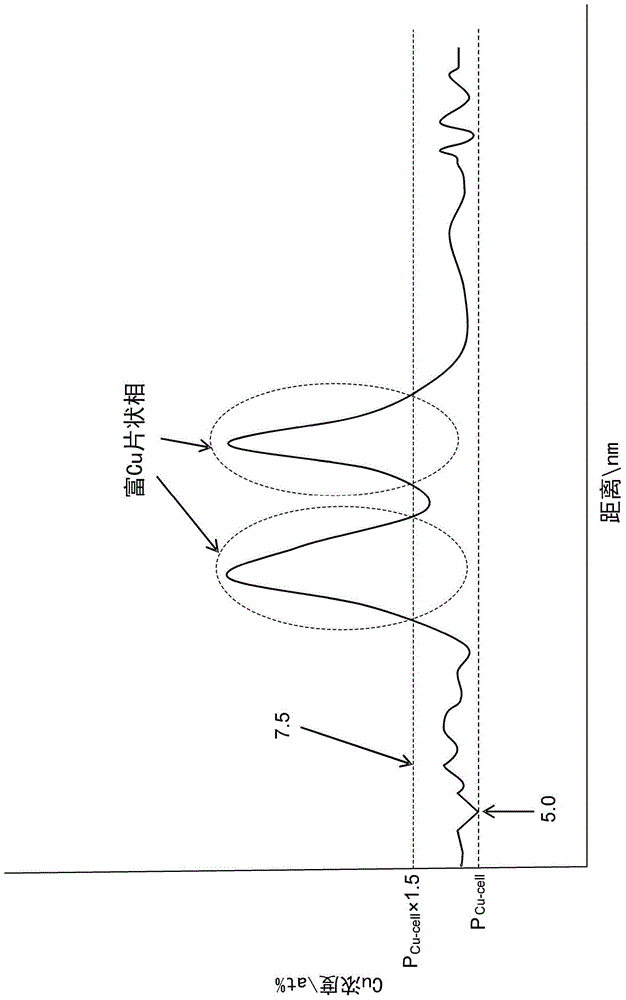

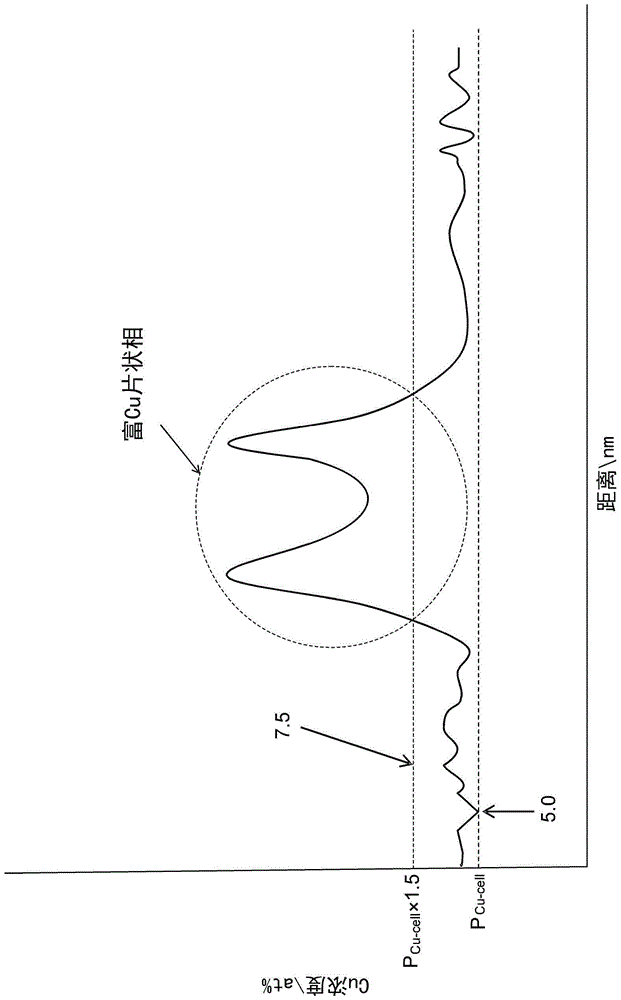

[0087] The raw materials used for the permanent magnet were weighed and mixed at a predetermined ratio, and then arc-dissolved in an Ar gas atmosphere to produce an alloy ingot. After the alloy ingot was heat-treated at 1175° C. for 8 hours, the alloy ingot was roughly pulverized and jet mill pulverized to prepare an alloy powder as a raw material powder of a magnet. The alloy powder is press-formed in a magnetic field to produce a compression-formed body.

[0088] Next, the compression molded body of the alloy powder was arranged in the sintering furnace chamber, and after the chamber was vacuumed, the temperature was raised to 1180° C. and held for 1 minute. After that, Ar gas was introduced, and the temperature was raised to 1195° C. in the Ar gas atmosphere. The temperature was maintained for 6 hours for formal sintering.

[0089] After the main sintering step, the sintered body was kept at 1160° C. for 8 hours to perform solution treatment. In addition, the cooling rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com