Block distributed noble metal composite oxide VOCs catalyst and preparation method thereof

A composite oxide and catalyst technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of unstable precious metals, poor anti-toxicity, and high prices, and achieves a balance between catalyst cost and performance. activity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

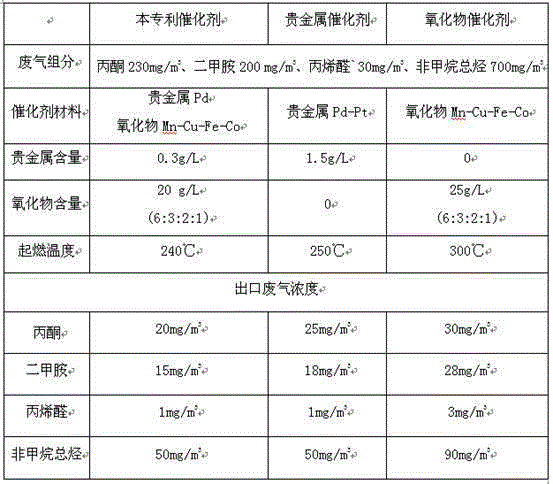

Embodiment 1

[0021] A block-distributed noble metal composite oxide VOC S The catalyst uses cordierite honeycomb ceramics as a carrier, and a basic coating is distributed on the honeycomb channels of the carrier, and the basic coating material includes γ-Al 2 o 3 , cerium-zirconium solid solution and oxide catalysts. The cerium-zirconium ratio of cerium-zirconium solid solution is 6:4, the oxide catalyst material is Mn-Cu-Fe-Co composite oxide, its total content is 15 g / L, and the mass ratio MnO:CuO:Fe 2 o 3 :Co 3 o 4 =8:3:1.5:2, the mass ratio of γ-Al2O3, cerium-zirconium solid solution, and oxide catalyst is 20:1:7.5. During the preparation process of the base coating, the oxide catalyst is fully mixed with alumina, step by step and penetrates into its microporous structure, and the thickness of the base coating is 0.4~0.5mm. A noble metal catalyst layer is distributed on the basic coating material, and the noble metal catalyst is more distributed and enriched in the surface layer...

Embodiment 2

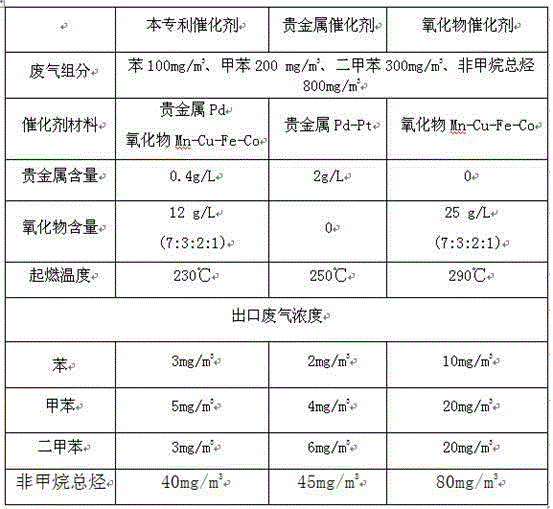

[0030] A block-distributed noble metal composite oxide VOC S The catalyst uses cordierite honeycomb ceramics as a carrier, and a basic coating is distributed on the honeycomb channels of the carrier, and the basic coating material includes γ-Al 2 o 3 , cerium-zirconium solid solution and oxide catalysts, etc. The cerium-zirconium ratio of cerium-zirconium solid solution is 4:6, the oxide catalyst material is Mn-Cu-Fe-Co composite oxide, the total content is 12 g / L, the mass ratio MnO:CuO:Fe 2 o 3 :Co 3 o 4 =7:3:2:1, the mass ratio of γ-Al2O3, cerium-zirconium solid solution, and oxide catalyst is 25:1:8. During the preparation process of the base coating, the oxide catalyst is fully mixed with alumina, step by step and penetrates into its microporous structure, and the thickness of the base coating is 0.4~0.5mm. A noble metal catalyst layer is distributed on the basic coating material, and the noble metal catalyst is more distributed and enriched in the surface layer po...

Embodiment 3

[0036] A block-distributed noble metal composite oxide VOC S The catalyst uses cordierite honeycomb ceramics as a carrier, and a basic coating is distributed on the honeycomb channels of the carrier, and the basic coating material includes γ-Al 2 o 3 , cerium-zirconium solid solution and oxide catalysts, etc. The cerium-zirconium ratio of cerium-zirconium solid solution is 3:7, the oxide catalyst material is Mn-Cu-Fe-Co composite oxide, the total content is 20 g / L, the mass ratio MnO:CuO:Fe 2 o 3 :Co 3 o 4 =6:3:2:1, the mass ratio of γ-Al2O3, cerium-zirconium solid solution, and oxide catalyst is 15:1:6. During the preparation process of the base coating, the oxide catalyst is fully mixed with alumina, step by step and penetrates into its microporous structure, and the thickness of the base coating is 0.4~0.5mm. A noble metal catalyst layer is distributed on the basic coating material, and the noble metal catalyst is more distributed and enriched in the surface layer po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com