Preparation method of form-adjustable anisotropic asymmetric emulsion particles

An anisotropic and asymmetric technology, applied in the field of synthesis of anisotropic asymmetric composite particles, can solve problems such as poor fluidity, inability to distinguish polymer surface protrusions from seeds, uncontrollable molecular weight and its distribution, etc., to achieve Ease of large-scale production and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

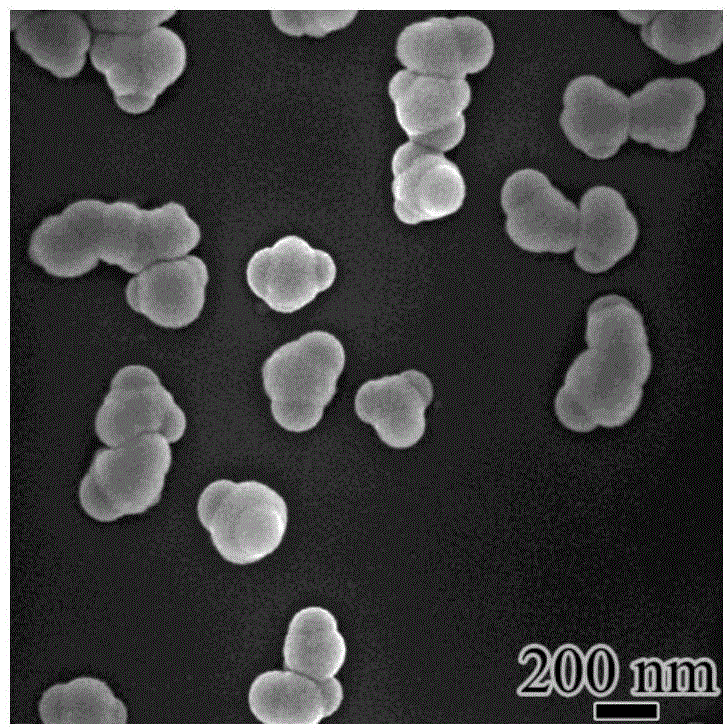

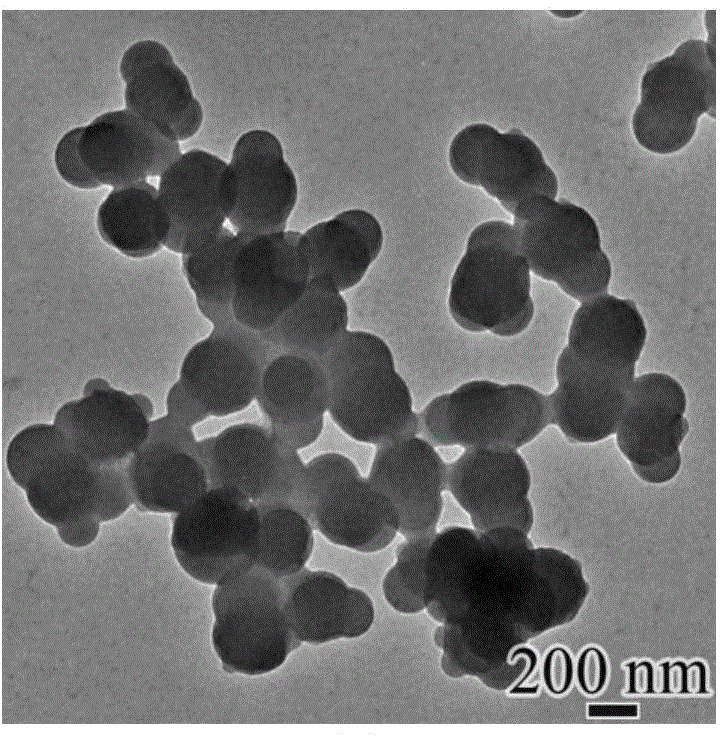

[0030] Implementation Case 1 Preparation of Anisotropic PVDF / PS Composite Particles

[0031]

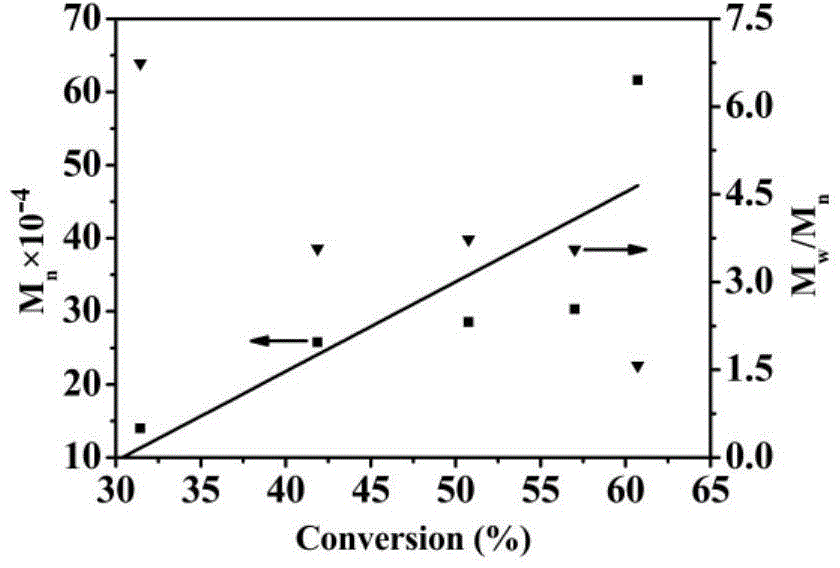

[0032] Add 6.67g of PVDF seed emulsion (industrial product) with a solid content of 15% and an average particle diameter of 180nm in a 100ml four-necked bottle equipped with mechanical stirring, reflux condenser and nitrogen inlet, ultrasonically disperse for 40 minutes, and add the monomer Styrene and initiator 2-bromopropionate methyl ester, simultaneously start stirring and feed nitrogen continuously, and the stirring rate is set at 250 rev / min. After 1.5 hours, add 0.14g of the ligand pentamethyldivinyltriamine and 0.13g of copper wire with a diameter of 1mm as the catalyst, and simultaneously perform vacuum pumping-nitrogen operation, and take samples every 1 hour to measure the molecular weight and its distribution. and distribution map attached image 3 shown, and then polymerized at a reaction temperature of 25°C for 5 hours. The emulsion samples were directly drawn from...

Embodiment example 2-3

[0039] The polymerization reaction time of implementation case 2-3 is 1 hour, 3 hours, and all the other implementation processes are the same as implementation case 1, and the SEM photograph of the composite particle form prepared by implementation case 2-3 is shown in the attachment Figure 4-5 .

[0040] attached by figure 1 , 3 4. It can be seen that the particle size of the asymmetric composite particles gradually increases and the surface protrusions gradually decrease with the prolongation of the polymerization time.

Embodiment example 4

[0042] In embodiment case 4, the add-on of changing monomer styrene is 0.5g, and the add-on of initiator 2-bromopropionate methyl ester is 0.008g, and the add-on of ligand pentamethyldivinyltriamine is 0.005g, and the catalyst The addition of the copper wire of diameter 1mm is 0.043g, and all the other implementation processes are the same as implementation case 1, and the SEM photograph of the composite particle form prepared by implementation case 4 is shown in the appendix Image 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com