Aqueous antimicrobial coating and preparation method thereof

An antibacterial, antifungal, and water-based technology, applied in the field of coatings, can solve the problems of coating film failure, high antibacterial rate, good antifungal effect, and low toxicity, and achieve the effects of beautiful coating film, high antibacterial and antifungal functions, and low toxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

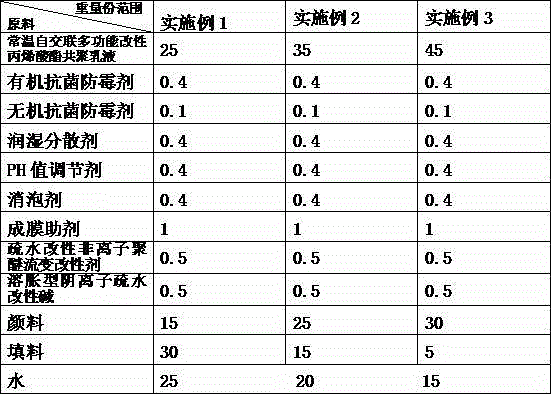

[0036] The preparation method of three embodiments of the water-based antibacterial and antifungal coating comprises the following steps

[0037] Steps:

[0038] (1) Mix water and wetting and dispersing agent evenly in the mixing tank until wetting and dispersing

[0039] agent dissolved in water;

[0040] (2) Add organic antibacterial and antifungal agents, inorganic antibacterial and antifungal agents, pigments and fillers to the above aqueous solution, and stir thoroughly to make the pigments and fillers completely wet;

[0041] (3) Send the above-mentioned mixture into dispersion equipment, such as a sand mill, for grinding, and the quality inspection controls the fineness to be ≤ 60 μm;

[0042] (4) Transfer the slurry obtained above to the paint mixing tank, and continue to add room temperature self-crosslinking multifunctional modified acrylate copolymer emulsion, defoamer, film-forming aid, hydrophobically modified non-ionic polyether rheological modification agent,...

Embodiment 1

[0045] Embodiment 1 performance test result is as follows:

[0046] Physical and chemical properties

[0047] serial number Test items unit standard requirement test result single conclusion 1 state in container — No lumps, homogeneous state after stirring conform to qualified 2 Construction — Applied secondary barrier-free conform to qualified 3 Coating Appearance — normal conform to qualified 4 Drying time (tack dry) h ≤2 ﹤2 qualified 5 Contrast Ratio (White) — ≥0.9 0.94 qualified 6 Alkali resistance (24h) — No abnormality No abnormality qualified 7 Scrub resistance Second-rate ≥300 310 qualified 8 Low temperature stability (3 cycles) class no deterioration No deterioration qualified

[0048] The inspection basis is: GB / T9756-2009 "Synthetic Resin Emulsion Interior Wall Coatings"

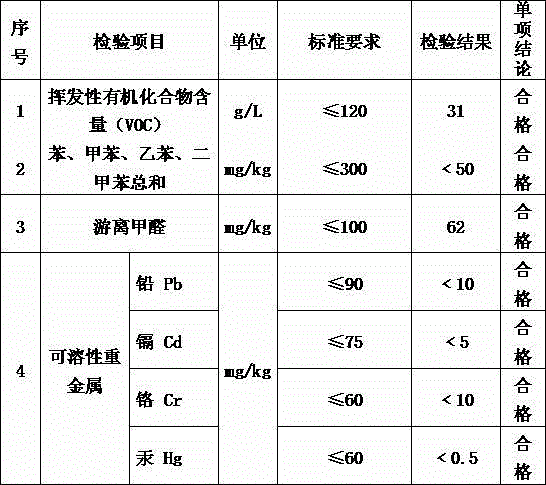

[0049] Limit of Hazardous Substances

[0050]

[0051] The inspection...

Embodiment 2

[0055] Embodiment 2 performance test result is as follows:

[0056] Physical and chemical properties

[0057] serial number Test items unit standard requirement test result single conclusion 1 state in container — No lumps, homogeneous state after stirring conform to qualified 2 Construction — Applied secondary barrier-free conform to qualified 3 Coating Appearance — normal conform to qualified 4 Drying time (tack dry) h ≤2 ﹤2 qualified 5 Contrast Ratio (White) — ≥0.9 0.96 qualified 6 Alkali resistance (24h) — No abnormality No abnormality qualified 7 Scrub resistance Second-rate ≥300 500 qualified 8 Low temperature stability (3 cycles) class no deterioration No deterioration qualified

[0058] The inspection basis is: GB / T9756-2009 "Synthetic Resin Emulsion Interior Wall Coatings"

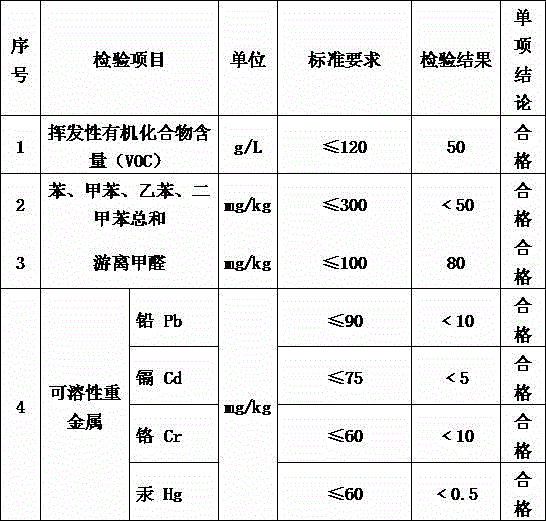

[0059] Limit of Hazardous Substances

[0060]

[0061]The inspection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com