A kind of chromium-containing low-carbon barbed wire steel and its production method

A production method and technology for barbed wire, applied in the direction of manufacturing converters, etc., can solve the problems of few production methods of steel wire rods for wire meshes, and no steel wire rods for low carbon wire rods containing chromium, etc., to ensure that the mechanical properties are qualified, The effect of preventing slag and ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

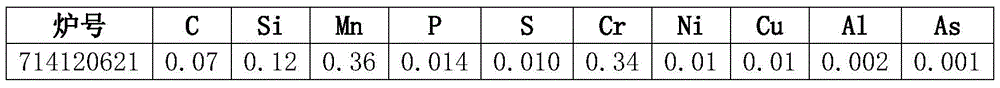

[0024] Embodiment 1 (stove number 714120621)

[0025] (1) Steel scrap, pig iron and molten iron raw materials are added to the converter. Among them, molten iron into the furnace: Si: 0.48%, P: 0.112%, S: 0.024%, temperature T = 1310 ° C, scrap steel accounts for 11% of the total raw materials; pig iron accounts for 3.5% of the total amount of raw materials; the total charge is 136t / furnace;

[0026] (2) During the converter smelting process, add 10.5t of slag material / furnace, and implement low-gun blowing operation, the final slag basicity is 3.6; the tapping end point [C]=0.05%, the end point [P]=0.014%, The tapping temperature is 1645°C, and 1 / 4 of the tapping time is followed by adding calcium carbide 120kg / furnace, aluminum cake 100kg / furnace, ferrosilicon 0.8kg / t, silicon-manganese alloy 3.9kg / t, and low-carbon ferrochrome 5.2kg in sequence. / t, lime 700kg / furnace and fluorite 120kg / furnace, the tapping time is 4 minutes, the slag blocking operation is adopted in the t...

Embodiment 2

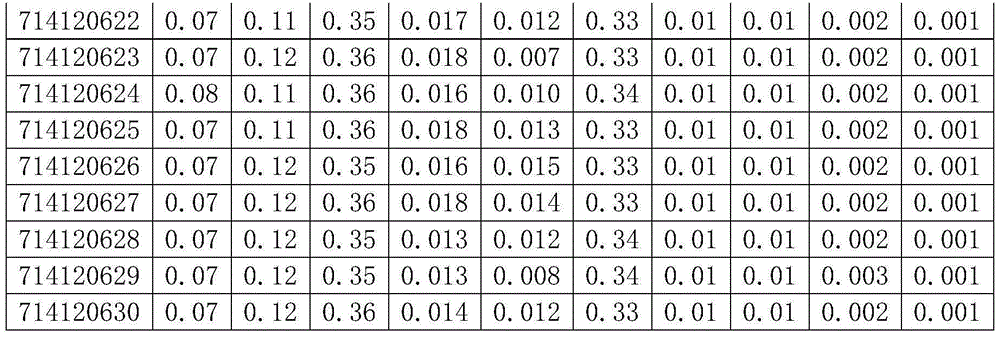

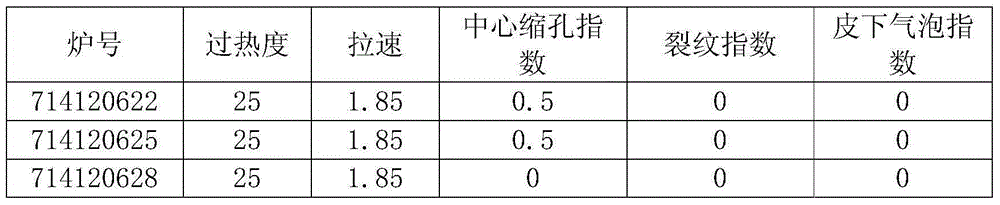

[0032] Embodiment 2 (stove number 714120622)

[0033] The superheat degree of the continuous casting furnace is 25°C, the casting speed is 1.85m / min, the furnace temperature in the soaking section of rolling is 1084°C, the rolling start temperature is 981°C, and the spinning temperature is 933°C, and the other operations are the same as in Example 1.

Embodiment 3

[0034] Embodiment 3 (stove number 714120623)

[0035] The total charging capacity of the converter is 135t / furnace, the end point of tapping [C]=0.06%, and the other operations are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com