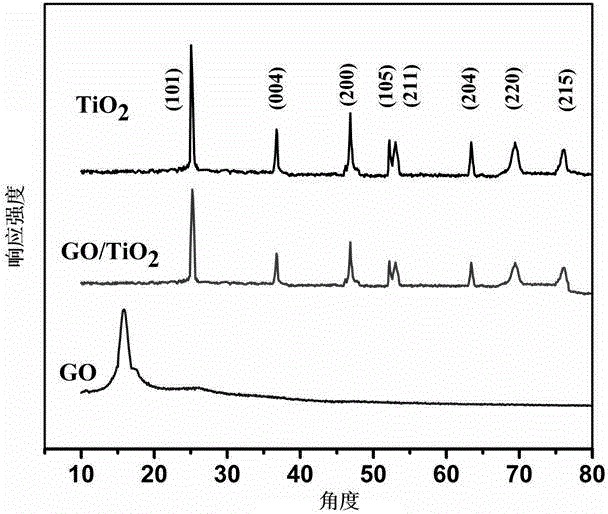

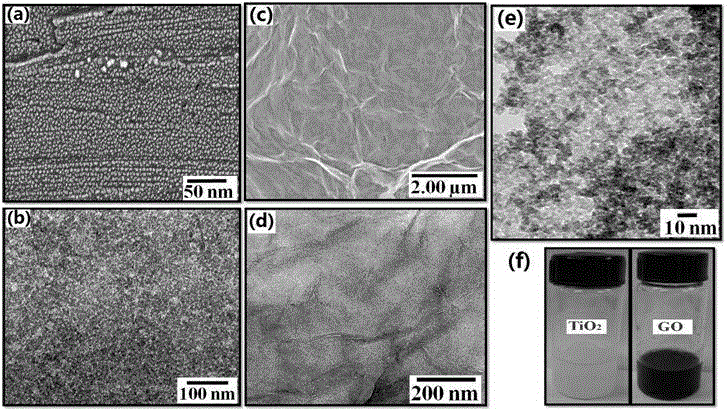

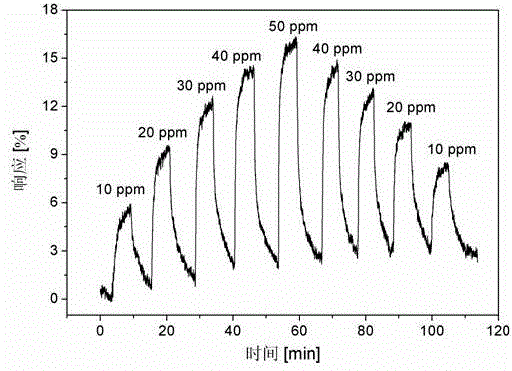

Graphene/titanium dioxide thin film gas sensor and preparation method thereof

A titanium dioxide and graphene technology, applied in instruments, scientific instruments, measuring devices, etc., to achieve the effects of uniform crystal size, high sensitivity and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] The manufacture method based on graphene / titanium dioxide sensitive film gas sensor of the present invention comprises the following steps:

[0040] 1) QCM substrate cleaning

[0041] The QCM substrate was soaked and cleaned in absolute ethanol and acetone, and dried for later use.

[0042] 2) Modification of QCM substrate

[0043] 1. The QCM substrate was treated with Pielka's reagent for 10 min to make it carry negatively charged groups such as carboxyl groups, and the treated QCM substrate was rinsed with deionized water for 1 min and dried with nitrogen. 2. Immerse in 1%wt polydimethyldiallyl ammonium chloride (PDDA) aqueous solution for 5 minutes, take it out and rinse it with deionized water for 1 minute and dry it with nitrogen. 3. The QCM substrate was immersed in sodium toluene sulfonate (PSS) for 5 min, rinsed with deionized water for 1 min and dried with nitrogen. Repeat step 2 and step 3 twice in sequence to modify the QCM substrate with two double layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com