A kind of electrolytic solution containing nitrile ethylamine and a kind of lithium secondary battery

A technology of nitrile ethylamine and electrolyte, which is applied in the field of lithium-ion battery preparation, can solve the problems of damage to battery high temperature performance and cycle performance, poor thermal stability, dry electrolyte, etc., to improve capacity recovery rate and oxidation resistance , Improve the effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

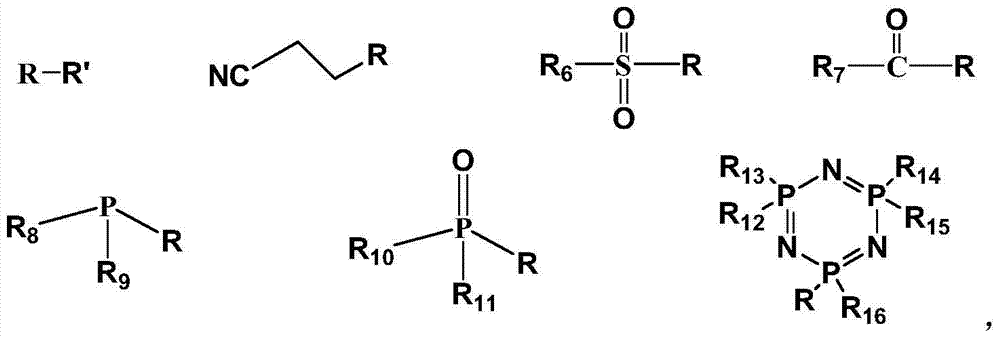

Method used

Image

Examples

Embodiment 1

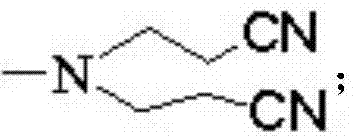

[0032] (1) Preparation of cyanoethylamine

[0033] Preparation of cyanoethylamine references (Organic Reaction, 1949, 5). chemical structure by 1 H-NMR and 19 As determined by F-NMR, the purity is confirmed by gas chromatography or liquid chromatography, and the product purity is greater than 99.95%.

[0034] (2) Preparation of electrolyte

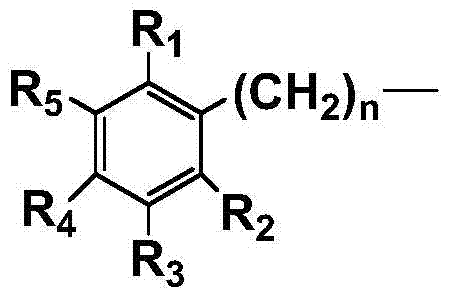

[0035] in an argon atmosphere glove box (H 2 O6 (1.0M) mixed, N,N-bisnitrile ethyl-p-fluorobenzylamine, VC (vinylene carbonate) and FEC (fluoroethylene carbonate) accounted for 1%, 0.5% and 3% of the total weight, respectively. The above-mentioned raw materials are added in sequence, fully stirred evenly, and the lithium secondary battery electrolyte (free acid<15ppm, moisture<10ppm) of the present invention is obtained. The prepared electrolyte was used for battery performance testing, and the test results are summarized in Table 1.

[0036] (3) Preparation of positive pole piece

[0037] Dissolve 3% polyvinylidene fluoride (PVDF) ...

Embodiment 2-28

[0045] Except the parameters in the following table, other parameters and preparation method are the same as in Example 1.

Embodiment 2-27

[0047]

[0048]

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com