Synthesis method for molybdenum disulfide nanosheet catalyst

A technology of molybdenum disulfide and synthesis method, which is applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low controllability and poor stability of nano molybdenum disulfide, and achieve reaction The effect of easy control of conditions, regular morphology and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 1.0 g of ammonium heptamolybdate tetrahydrate into the lining of a polytetrafluoroethylene hydrothermal kettle, and weigh 0.35g of sulfur powder into the lining of a polytetrafluorohydrothermal kettle to make the Mo:S ratio 1:2. Add 12ml of deionized water and 4ml of hydrazine hydrate reducing agent to the lining of the Teflon hydrothermal kettle. Transfer the hydrothermal kettle lining to a stainless steel hydrothermal kettle and seal it. Hydrothermal reaction at 140-180°C for 5-48 hours, natural cooling to room temperature, suction filtration, washing, and drying in a vacuum oven to obtain black solid molybdenum disulfide nanosheets.

Embodiment 2

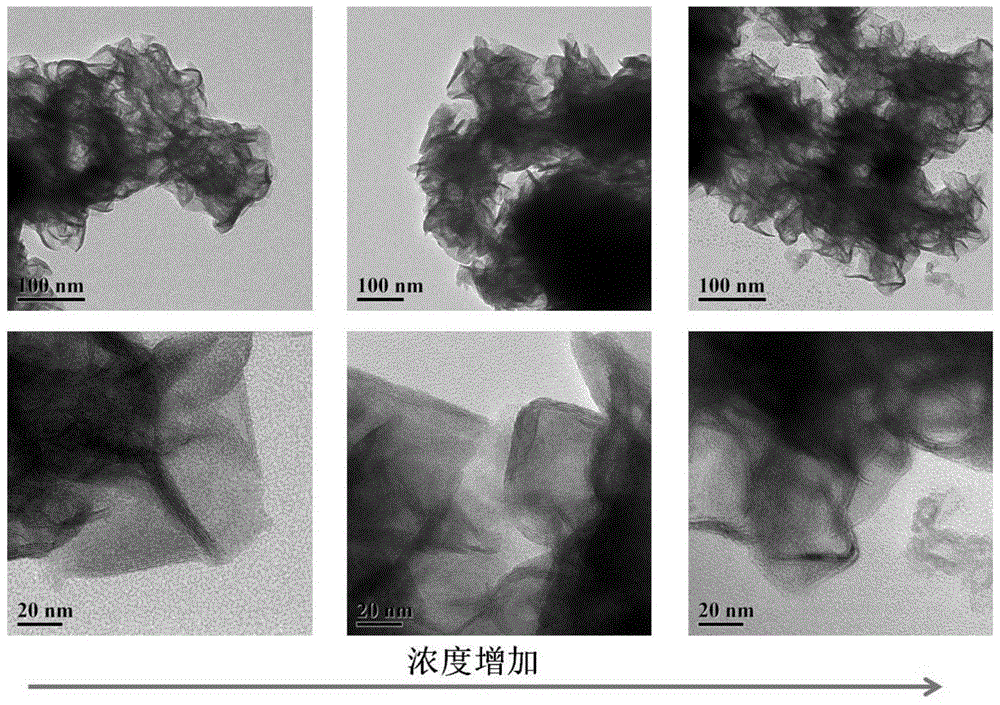

[0020] Weigh 0.1-1g of ammonium heptamolybdate tetrahydrate into the lining of the polytetrafluoroethylene hydrothermal kettle, weigh 0.035-0.35g of sulfur powder into the lining of the polytetrafluorohydrothermal kettle, so that the Mo:S ratio is 1:2. Add 20ml of deionized water and 1-8ml of 80% hydrazine hydrate reducing agent to the lining of the Teflon hydrothermal kettle. The lining of the hydrothermal kettle is transferred to a stainless steel hydrothermal kettle and sealed. Hydrothermal reaction at 160°C for 48 hours, natural cooling to room temperature, suction filtration, washing, and drying in a vacuum oven to obtain black solid molybdenum disulfide nanosheets.

Embodiment 3

[0022] Weigh 1.0g of ammonium heptamolybdate tetrahydrate into the lining of a polytetrafluoroethylene hydrothermal kettle, and weigh 0.35g of sulfur powder into the lining of a polytetrafluorohydrothermal kettle to make the Mo:S ratio 1:2. Add 12ml of deionized water and 8ml of 80% hydrazine hydrate reducing agent to the lining of the PTFE hydrothermal kettle. The lining of the hydrothermal kettle is transferred to a stainless steel hydrothermal kettle and sealed. Hydrothermal reaction at 160°C for 48 hours, natural cooling to room temperature, suction filtration, washing, and drying in a vacuum oven to obtain black solid molybdenum disulfide nanosheets.

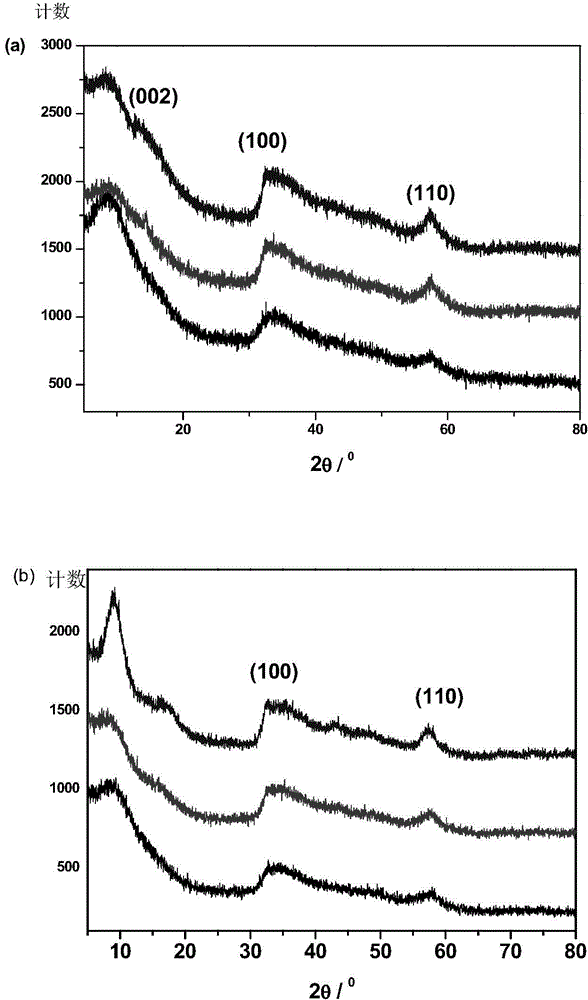

[0023] See figure 1 . From figure 1 According to XRD, the characteristic diffraction peak of the molybdenum disulfide nanosheets prepared in Example 1 of the present invention is 2H-type molybdenum disulfide. among them figure 1 The (002) diffraction peak of the XRD spectrum of the molybdenum disulfide prepared by prolonging...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com