Method for purifying oxidized graphene

A purification method and graphene technology, applied in the field of graphene oxide purification, can solve the problems of high purification cost of graphene oxide, inability to generate large area, restricting graphene, etc., achieving controllable purification process, realizing macro-scale preparation, Effects without equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Graphite oxide was prepared by the modified Hummers method using 325 mesh natural flake graphite. The pH of the obtained graphite oxide solution is 0.5, the concentration is 50 mg / mL, add deionized water and stir evenly, let it stand for 12 hours until the graphite oxide is separated from the water phase, remove the last clear liquid, then add 500 ml of water, let it stand for precipitation, repeat Several times until the graphene oxide solution turns from bright yellow to dark brown. The pH of the graphite oxide solution was tested to be 1.0, the concentration was 8 mg / ml, and the graphene oxide solution was obtained by ultrasonication for 30 minutes. The solution was packaged in a 400-mesh nylon fabric bag, and placed in a circulating deionized water pool for cleaning, dialysis, and water storage. The mass ratio of water to graphene oxide is 10:1. Repeatedly replace the deionized water several times to increase the concentration difference inside and outside, and acce...

Embodiment 2

[0023] The preparation method of graphene oxide solution and the primary purification of graphite oxide solution are the same as in Example 1. Test that the graphite oxide solution cannot be independently separated and pre-purified again under the condition of pH=1.5. Adjust the concentration at 4 mg / ml, and obtain a graphene oxide solution by ultrasonication for 1 h. The solution is packaged in a 600-mesh nylon fabric bag and placed in a Dialysis and purification in deionized water, the mass ratio of water storage to graphene oxide is 20:7, repeated replacement of deionized water several times, increasing the concentration difference inside and outside, accelerating the dialysis speed, and testing the pH of the graphene oxide solution inside the nylon fabric bag after 9 days= 4.0, collect the graphene oxide dispersion, and freeze-dry to prepare graphene oxide powder.

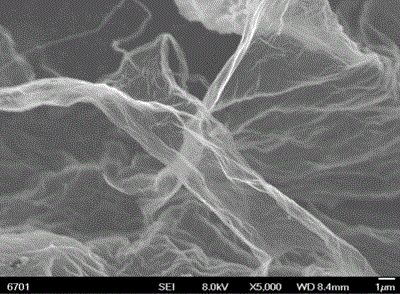

[0024] Electron microscope observation results show that the few layers of graphene oxide prepared under thi...

Embodiment 3

[0026] The preparation method of graphene oxide solution and the primary purification of graphite oxide solution are the same as in Example 1. Test that the graphite oxide solution cannot be independently separated again under the condition of pH=1.0. The pre-purification is completed. Adjust the concentration at 2 mg / ml, and obtain a graphene oxide solution by ultrasonication for 1 h. The solution is packaged in an 800-mesh nylon fabric bag, and placed in a Purification by dialysis in deionized water, the mass ratio of water storage capacity to graphene oxide is 5:1, repeated replacement of deionized water several times, increasing the concentration difference inside and outside, and accelerating the dialysis speed. After 10 days, test the pH of the graphene oxide solution inside the nylon fabric bag= 3.0, collecting the graphene oxide dispersion, freeze-drying, and preparing graphene oxide powder.

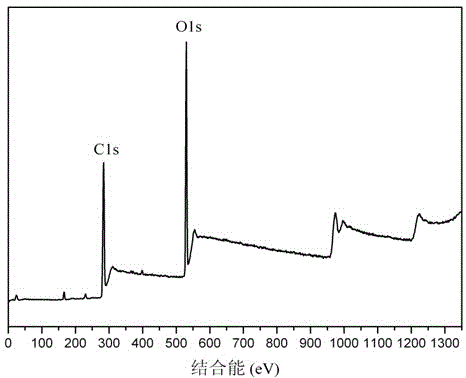

[0027] The composition analysis results show that the graphene oxide prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com