A kind of preparation method of ag-sio2-ag nanosphere array

A technology of ag-sio2-ag and nanospheres, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the difficulty of uniform dispersion of core-shell nanoparticles, SiO2 difficulties, and weak substrate bonding, etc. problem, achieve the effect of enhancing sensitivity and improving light permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

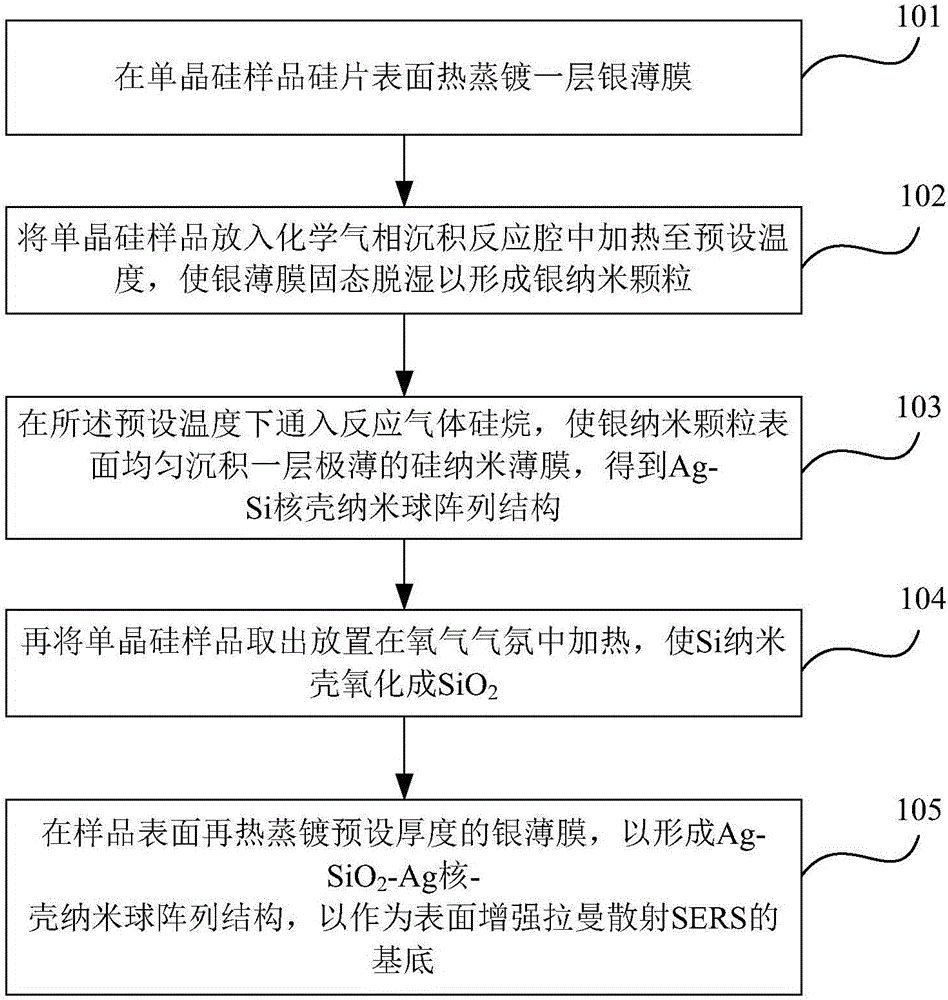

[0032] Such as figure 1 As shown, it is a kind of Ag-SiO in the embodiment of the present invention 2 -A flow chart of the preparation method of the Ag nanosphere array, the method comprising:

[0033] 101. Thermally evaporate a layer of silver thin film on the surface of the single crystal silicon sample silicon wafer;

[0034] 102. Put the monocrystalline silicon sample into the chemical vapor deposition reaction chamber and heat it to the preset temperature, so that the silver film can be dehumidified by solid state to form silver nanoparticles;

[0035] 103. Passing reaction gas silane at the preset temperature, so that a layer of extremely thin silicon nanofilm is uniformly deposited on the surface of silver nanoparticles, and an Ag-Si core-shell nanosphere array structure is obtained;

[0036] 104. Take out the single crystal silicon sample and heat it in an oxygen atmosphere to oxidize the Si nanoshell into SiO 2 ;

[0037] 105. Reheat vapor-deposit a silver film wi...

Embodiment 1

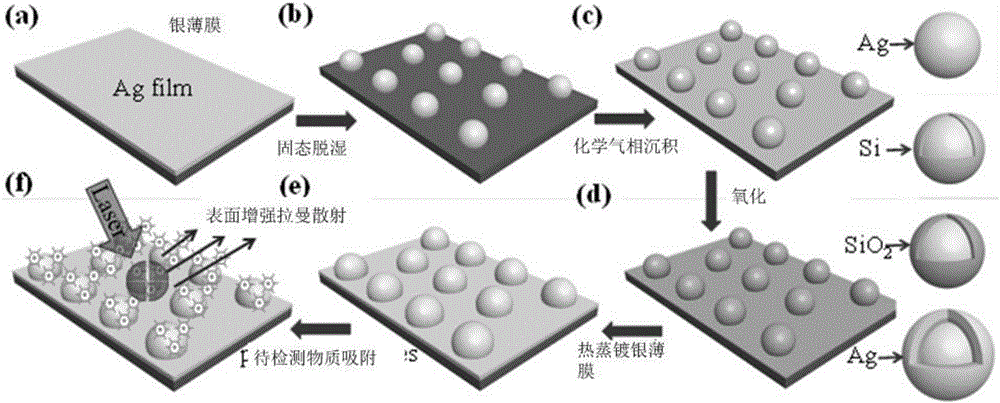

[0057] This example provides a method for preparing a surface Raman-enhanced active substrate based on chemical vapor deposition. The preparation process is as follows figure 2 As shown, (a) a layer of Ag thin film is thermally evaporated on a smooth silicon substrate, (b) heated and annealed in the CVD reaction chamber to form Ag nanoparticles on the surface of the silicon substrate, (c) the reaction chamber is introduced into the reaction chamber gas to obtain the Ag-Si core-shell nanosphere array, (d) take the sample out and heat it in an oxygen atmosphere to obtain the Ag-SiO 2 Core-shell nanosphere array, (e) thermally evaporated a layer of Ag thin film to obtain Ag-SiO 2 -SERS substrate of Ag core-shell nanosphere array, (f) The substance to be detected is adsorbed on the SERS substrate for Raman detection.

[0058] The technical solution of the present invention will be further described below.

[0059] Pretreatment: Ultrasonic cleaning of 2.5cm×5cm silicon wafers ac...

Embodiment 2

[0066] This example provides a method for preparing a surface Raman-enhanced active substrate based on chemical vapor deposition. The preparation process is as follows figure 2 As shown, (a) a layer of Ag thin film is thermally evaporated on a smooth silicon substrate, (b) heated and annealed in the CVD reaction chamber to form Ag nanoparticles on the surface of the silicon substrate, (c) the reaction chamber is introduced into the reaction chamber gas to obtain Ag-Si core-shell nanosphere arrays, (d) take out the sample and place it in clean air for heating and oxidation to obtain Ag-SiO 2 Core-shell nanosphere array, (e) thermally evaporated a layer of Au film to obtain Ag-SiO 2 - The SERS substrate of the Au core-shell nanosphere array, (f) the substance to be detected is adsorbed on the SERS substrate for Raman detection.

[0067] The technical solution of the present invention will be further described below.

[0068] Pretreatment: Ultrasonic cleaning of 2.5cm×5cm sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com