Method for preparing binary copolymerized water hyacinth carboxymethyl cellulose super absorbent resin

A technology of carboxymethyl cellulose and super absorbent resin, which is applied in the field of preparation of cellulose-based super absorbent resin, achieves the effects of simple synthesis process operation and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

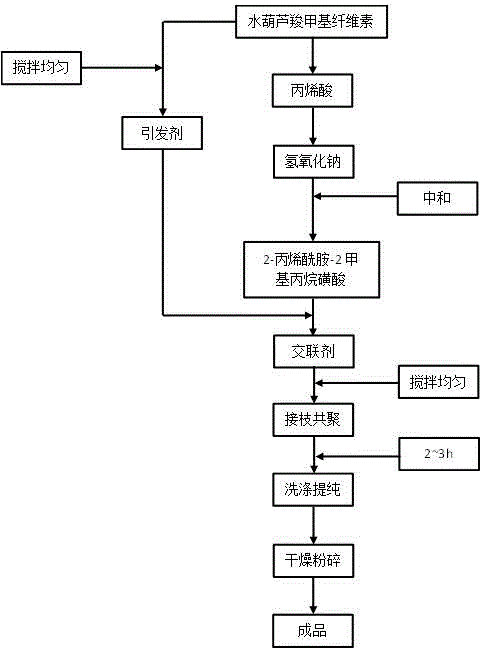

Method used

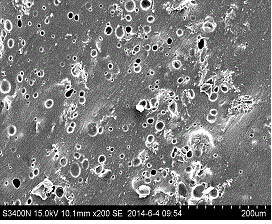

Image

Examples

Embodiment 1

[0024] Weigh 5g water hyacinth carboxymethyl cellulose, fully dissolve it with deionized water and stir at 35°C, add 0.90g potassium persulfate, and continue stirring for 10 minutes to pre-initiate; prepare 21g NaOH solution and place it in an ice-water bath, and slowly add it to In 38g of acrylic acid solution, adjust the degree of neutralization to 80%, add 6.75g of 2-acrylamide-2 methylpropanesulfonic acid and 0.1g of N,N'-methylenebisacrylamide to the above solution, and stir fully to obtain a mixed solution; The solution is added to the pre-initiated water hyacinth carboxymethyl cellulose solution, so that the volume of the reaction system is 60ml, and the stirring is continued to obtain the final mixed solution; 6gspan-60 and 200ml cyclohexane are added to the three ports with a condenser tube and a nitrogen conduit. In the flask, heat a 500ml three-necked flask in a 35°C oil bath to completely dissolve the oil phase; add the above-mentioned final mixture to the oil phase...

Embodiment 2

[0026] Weigh 7g water hyacinth carboxymethyl cellulose, fully dissolve it with deionized water and stir at 35°C, add 0.57g potassium persulfate, and continue stirring for 10min to pre-initiate; prepare 11.7g NaOH solution and place it in an ice-water bath, and slowly Add it to 30g of acrylic acid solution, adjust the degree of neutralization to 70%, add 20g of 2-acrylamide-2 methylpropanesulfonic acid, 0.09g of N,N'-methylenebisacrylamide to the above solution, and stir thoroughly to obtain a mixed solution; Add the mixed solution to the pre-initiated water hyacinth carboxymethyl cellulose solution, so that the volume of the reaction system is 65ml, and continue to stir to obtain the final mixed solution; In the three-necked flask of the conduit, heat the 500ml three-necked flask in an oil bath at 35°C to completely dissolve the oil phase; add the above-mentioned final mixed solution to the oil phase, fill with nitrogen and exhaust oxygen for 15 minutes, and set the initial tem...

Embodiment 3

[0028]Weigh 10g water hyacinth carboxymethyl cellulose, fully dissolve it with deionized water and stir at 35°C, add 0.50g potassium persulfate, and continue stirring for 10 minutes to pre-initiate; prepare 10.7g NaOH solution and place it in an ice-water bath, and slowly add Add 10g of 2-acrylamide-2 methylpropanesulfonic acid and 0.05g of N,N'-methylenebisacrylamide to the above solution, adjust the degree of neutralization to 65%, and stir thoroughly to obtain a mixed solution; The solution is added to the pre-initiated water hyacinth carboxymethyl cellulose solution, so that the volume of the reaction system is 70ml, continue to stir to obtain the final mixed solution; add 4.6g span-60, 150ml cyclohexane Put a 500ml three-necked flask in a 35°C oil bath and heat it to completely dissolve the oil phase; add the above-mentioned final mixed solution into the oil phase, fill with nitrogen and exhaust oxygen for 15 minutes, and set the initial temperature to 40°C. The temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com