Production method for continuously synthesizing polyether amine through static bed

A production method and a technology for chemical synthesis, which are applied in the field of continuous synthesis of polyetheramines in a fixed bed, can solve problems such as being unsuitable for large-scale industrialization, high reaction pressure and temperature, insufficient ammonia conversion rate, etc., and achieve easy automatic control, Low pressure and temperature, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

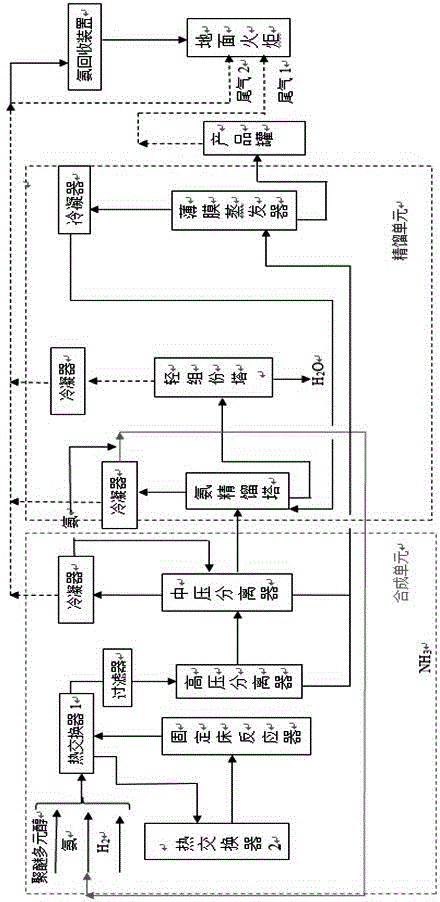

Image

Examples

Embodiment 1

[0023] Activated skeleton nickel catalyst: The skeleton nickel catalyst used is supported by alumina, and the supported metal content (reduced state) is: 60% nickel, 10% copper, and 3% lanthanum. The catalyst is loaded in the reactor in sections, and the reduction temperature is 150°C, the heating rate is 0.1°C / min, and the reduction time is 40h, to obtain a fixed-bed reactor containing an activated skeleton nickel catalyst loaded with nickel, copper and lanthanum.

[0024] Preparation of polyether amine: first pour polypropylene glycol ether (molecular weight 200) and liquid ammonia into each raw material tank respectively, and then pour polypropylene glycol ether and liquid ammonia into the pipeline with a volume ratio of 1:1.35 after being metered by a metering pump Mix, and then spray through the nozzle to form a uniform mixed liquid, and then fully mix the mixed liquid with hydrogen (the hydrogen source is continuously provided by decompression of the pressure regulator) a...

Embodiment 2

[0028] Activated skeleton nickel catalyst: The skeleton nickel catalyst used is based on alumina as the carrier, and the supported metal content (reduced state) is: nickel 70%, copper 8%, lanthanum 2%; the catalyst is packed in the reactor in sections, after reduction The temperature is 270° C., the heating rate is 1° C. / min, and the reduction time is 30 h, and a fixed-bed reactor containing an activated skeleton nickel catalyst loaded with nickel, copper and lanthanum is obtained.

[0029] Preparation of polyether amine: Pour polypropylene glycol ether (molecular weight: 2000) and liquid ammonia into the raw material tank respectively. After the polypropylene glycol ether and liquid ammonia are metered by the metering pump, they are poured into the pipeline with a volume ratio of 1:1.98 for mixing. Then spray through the nozzle to form a uniform mixed liquid, and then fully mix the mixed liquid with hydrogen (the hydrogen source is continuously provided by a pressure regulator...

Embodiment 3

[0033] Activated skeleton nickel catalyst: The skeleton nickel catalyst used is based on silicon oxide, and the supported metal content (reduced state) is: 80% nickel, 5% copper, and 1.5% lanthanum; the catalyst is mixed in the reactor, and the reduction temperature 300° C., a heating rate of 2° C. / min, and a reduction time of 25 hours to obtain a fixed-bed reactor containing an activated skeleton nickel catalyst loaded with nickel, copper, and lanthanum.

[0034] Preparation of polyether amine: Pour trimethylolpropane polypropylene glycol ether (molecular weight 430) and liquid ammonia into the raw material tank respectively, and trimethylolpropane polyoxypropylene ether and liquid ammonia are respectively measured by a metering pump and then calculated according to the volume ratio The ratio of 1:2.29 is poured into the pipeline for mixing, and then sprayed through the nozzle to form a uniform mixed liquid, and then the mixed liquid and hydrogen (the hydrogen source is contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com