In-situ representation performance testing method based on single nano-wire electrode material

A technology of electrode materials and testing methods, applied in nanotechnology, hybrid capacitor electrodes, semiconductor/solid-state device testing/measurement, etc., can solve problems such as poor conductivity, small specific surface, and poor conductivity of oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: MnO 2 Preparation method of nanowire material

[0016] 1) Dissolve 1mmol potassium permanganate powder in deionized water, add 2mmol ammonium fluoride, stir at room temperature for 10-20 minutes, and stir evenly;

[0017] 2) Transfer the solution obtained in step 1) into a 100mL reactor, react at 180°C for 3 hours, take out the reactor, and cool to room temperature naturally;

[0018] 3) Wash the product obtained in step 2) repeatedly with absolute ethanol, and dry to obtain MnO 2 Nanowires.

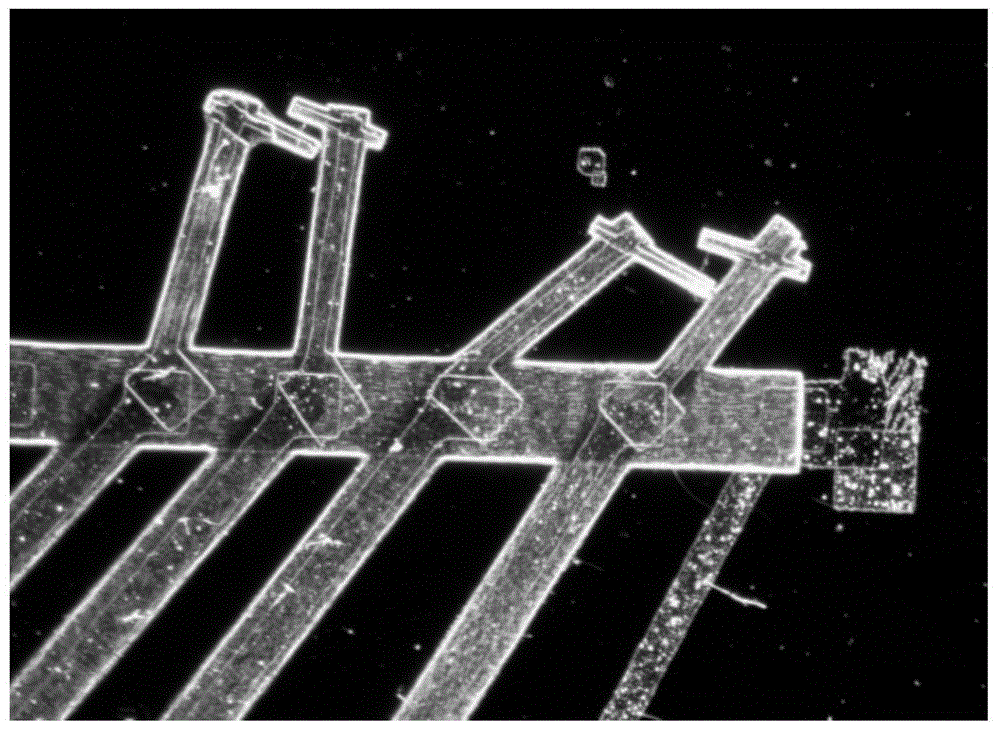

[0019] With the MnO that this embodiment makes 2 The diameter of the nanowire is 30-90nm, and the length is 10-30μm. And the distribution is relatively uniform.

Embodiment 2

[0020] Example 2: MnO 2 Preparation method of coaxial nanowire material with midline structure in / rGO tube

[0021] 1) Dissolve 1mmol potassium permanganate powder in deionized water, add 2mmol ammonium fluoride, stir at room temperature for 10-20 minutes, and stir evenly;

[0022] 2) Add 2ml graphene dispersion in proportion to the solution obtained in step 1), and stir for 10-15 minutes;

[0023] 3) Transfer the solution obtained in step 2) into a 100mL reactor, react at 180°C for 3 hours, take out the reactor, and cool to room temperature naturally;

[0024] 4) Wash the product obtained in step 3) repeatedly with absolute ethanol, and dry to obtain MnO 2 / rGO tube midline nanowires.

[0025] With the MnO that this embodiment makes 2 / rGO nanowire diameter is 40-150nm, where MnO 2 The diameter is 35-120nm, the length is 15-40μm, and the distribution is relatively uniform.

Embodiment 3

[0026] Embodiment 3: porous graphene / MnO 2 Preparation method of coaxial nanowire material with tube centerline structure

[0027] 1) Dissolve 1mmol potassium permanganate powder in deionized water, add 2mmol ammonium fluoride, stir at room temperature for 10-20 minutes, and stir evenly;

[0028] 2) Add 2ml graphene dispersion in proportion to the solution obtained in step 1), and stir for 10-15 minutes;

[0029] 3) Transfer the solution obtained in step 2) into a 100mL reactor, react at 180°C for 3 hours, take out the reactor, and cool to room temperature naturally;

[0030] 4) The product obtained in step 3) is soaked and reduced in 5mmol / L hydrazine hydrate for 2h and then taken out;

[0031] 5) Wash the product obtained in step 4) repeatedly with absolute ethanol, and dry to obtain porous graphene / MnO 2 Tube centerline structure coaxial nanowires.

[0032] With the MnO that this embodiment makes 2 / pGO nanowire diameter is 40-150nm, where MnO 2 The diameter is 35-120...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com