Catalyst for catalyzing efficient conversion of silane to silanol, preparation and application thereof

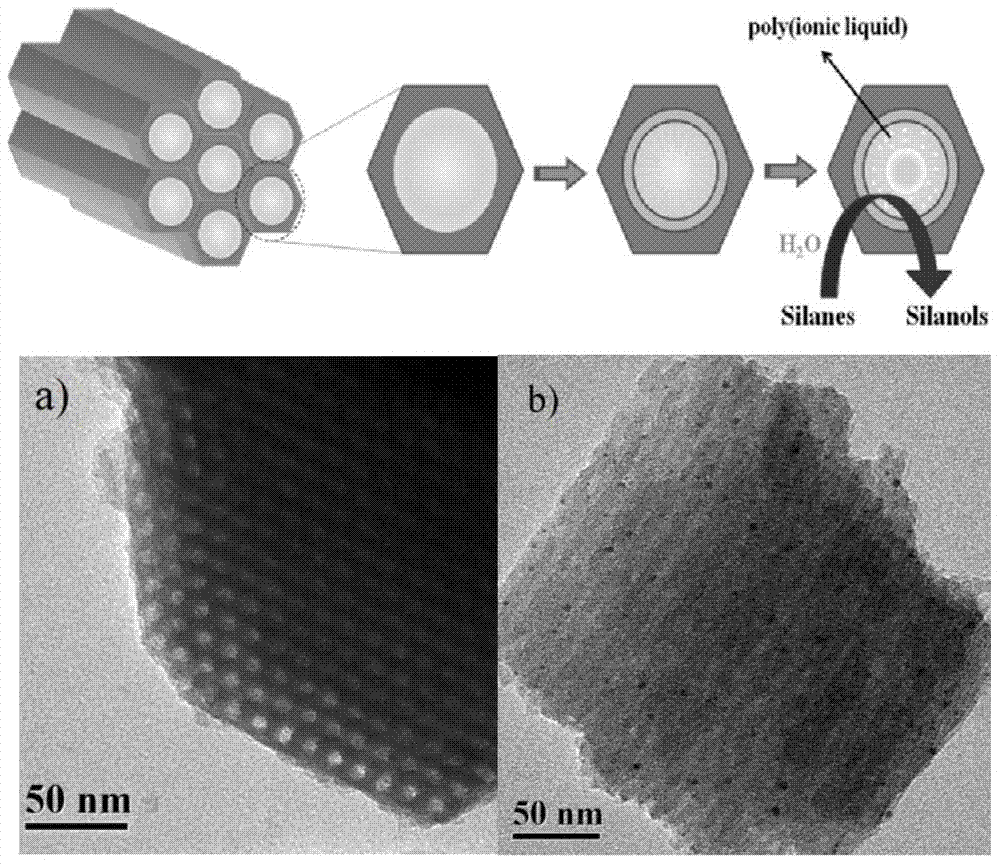

A technology for catalyzing silane and catalysts, which is applied in the field of preparation of new heterogeneous catalysts SBA-PIL-Au, which can solve problems such as difficulty and lack of interaction force, and achieve high loading capacity, exquisite preparation route design, and the effect of inhibiting agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

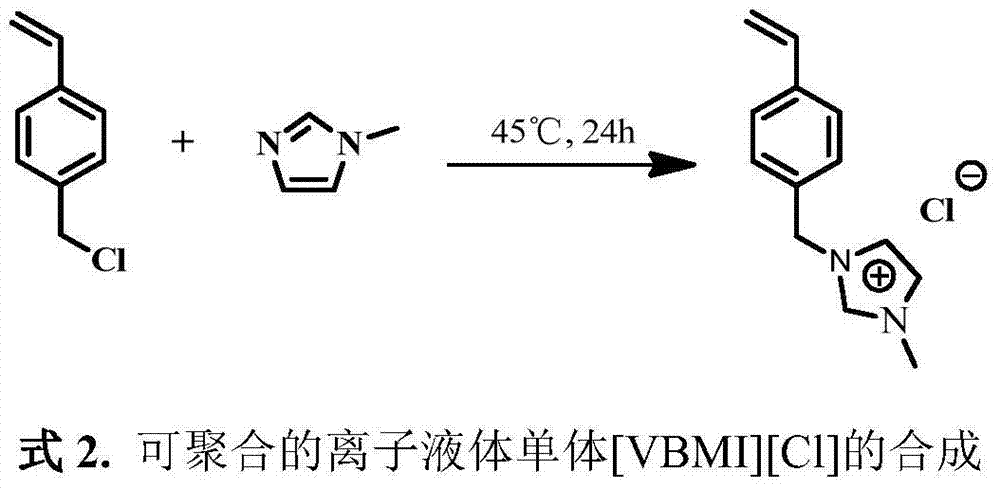

[0034] The first step: the synthesis of [VBMI][Cl]: 4-(chloromethyl)styrene (1.53g, 10mmol) and 1-methylimidazole (0.82g, 10mmol) were blended and reacted at 45°C under nitrogen protection 24h. After the reaction was finished, cool to room temperature, filter and wash the precipitate, and dry it in vacuum.

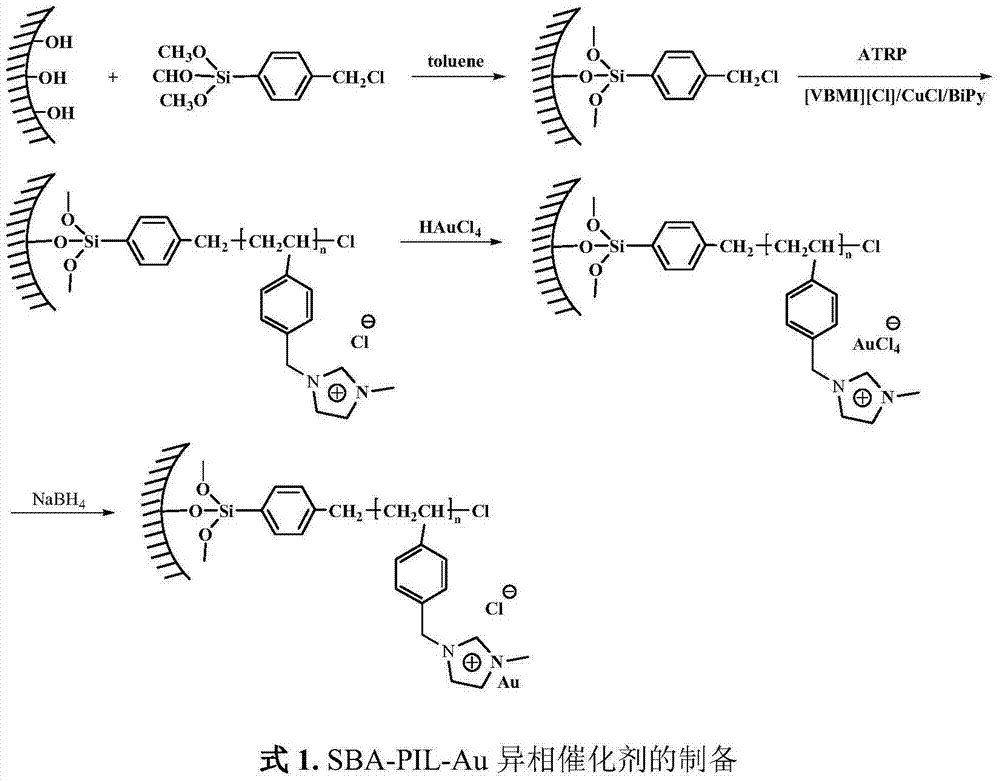

[0035] The second step: SBA-15 surface modification initiator CTS

[0036] SBA-15 was mixed with 17% HCl solution and refluxed for 4 hours to expose as many silicon hydroxyl groups as possible on the surface of SBA-15. The treated SBA-15 (2.0g) was mixed with CTS (1.0g), toluene (40mL) and pyridine (1.0g) and then stirred and refluxed for 16h under nitrogen protection. The product was washed successively with acetone and water, and then dried under vacuum at 100°C overnight. The surface of SBA-15 was successfully grafted with chlorine-containing ATRP initiator CTS.

[0037] Step 3: Grafting PIL on the surface of SBA-CTS

[0038] Ionic liquid polymer brushes were in si...

Embodiment 2-4

[0044] SBA-PIL-Au catalyzes the conversion reaction of triethylsilane to triethylsilanol, and the catalytic performance does not decline at all after being recycled for 3 times. According to Table 1, other preparation, reaction, and test conditions are the same as in Example 1. .

[0045] Table 1

[0046]

Embodiment 5-11

[0048] SBA-PIL-Au shows high conversion rate and high selectivity to a series of different kinds of silane to silanol conversion reactions, as described in Table 2, and other preparation, reaction and test conditions are the same as in Example 1.

[0049] Table 2

[0050]

[0051] The present invention successfully prepares SBA-15 supported Au nano particle heterogeneous catalyst SBA-PIL-Au for the first time, and uses it to catalyze the efficient conversion of silane to silanol. In order to enhance the interaction force between the substrate and the gold nanoparticles, we innovatively propose an ionic liquid polymer brush (PIL): poly(1-(4-enylphenyl)-3-methylimidazolium chloride ) in situ grafted onto the pore wall of SBA-15. SBA-PIL-Au showed high conversion and high selectivity for a series of conversion reactions of different kinds of silanes to silanols. After the catalyst is recycled for 3 times, the catalytic performance does not decrease at all, and only water is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com