Mesoporous ZSM-5 molecular sieve and preparation method thereof

A ZSM-5, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the complex post-processing method steps, expensive template agent, small mesopore volume, etc. problems, to achieve good industrial application prospects, good structural stability, and the effect of large mesopore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a kind of mesoporous ZSM-5 molecular sieve, which is prepared by the following steps:

[0032] Add 450g of distilled water and 13g of sodium hydroxide into the beaker in turn, control the temperature in the beaker to 60°C, add 4.3g of ZSM-5 seed crystals, stir for 0.5h, then add 78g of diatomite, stir for 0.5h to dissolve, then add 2.7g of aluminum sulfate , after stirring for 1 h, the reaction mixture was obtained;

[0033] The reaction mixture was put into a reaction kettle, crystallized at 170°C for 24 hours, then filtered, washed, and dried to obtain ZSM-5 zeolite, which was designated as G-1 sample.

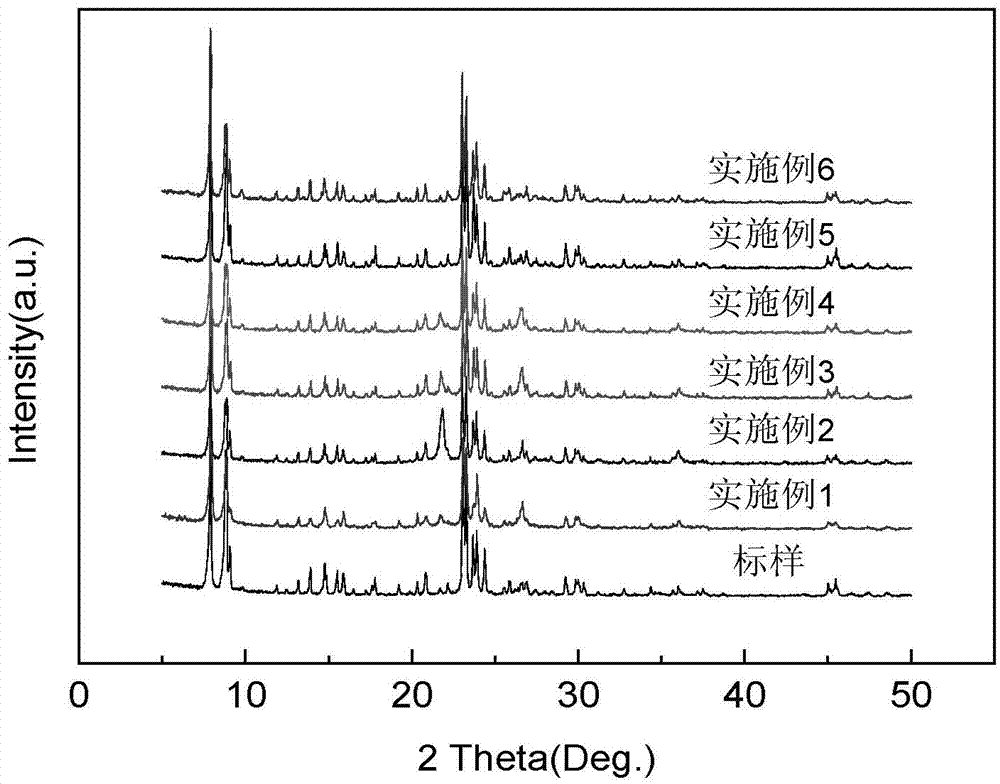

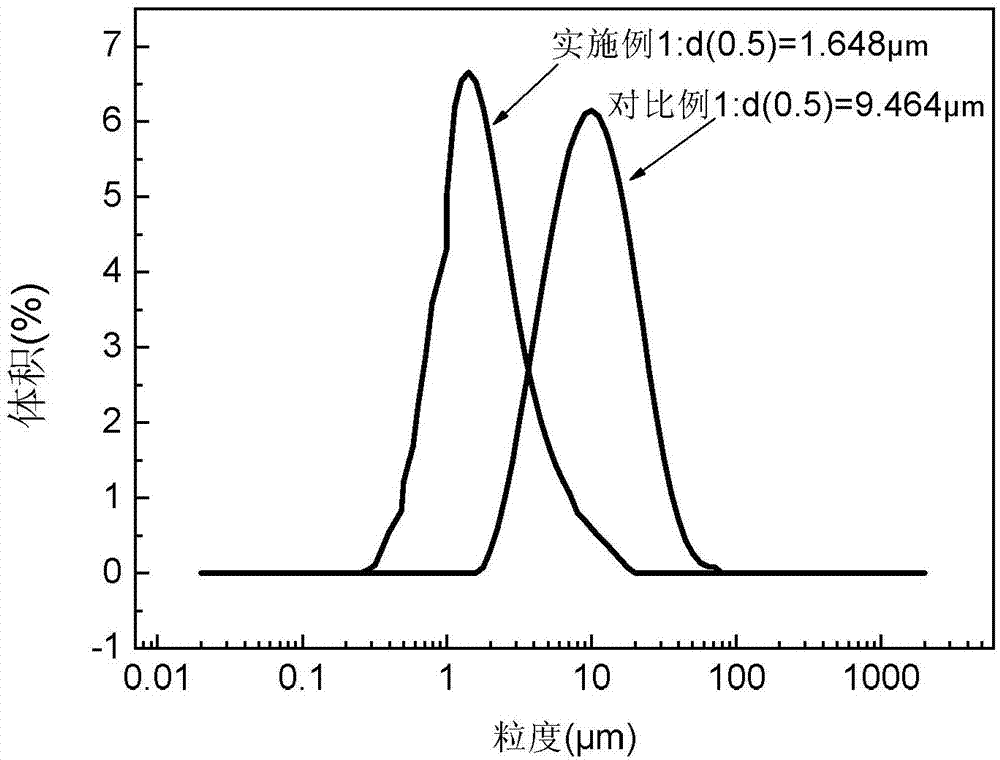

[0034] The relative crystallinity of the mesoporous ZSM-5 molecular sieve determined by XRD ray diffraction is 64%, and the diffraction spectrum whose scanning range 2θ is 5-50° is shown in figure 1 , the median diameter is about 1.65μm (see the pore size distribution diagram figure 2 ), the mesopore volume of the product is 0.058cm higher ...

Embodiment 2

[0041] This embodiment provides a kind of mesoporous ZSM-5 molecular sieve, which is prepared by the following steps:

[0042] Add 335g of distilled water and 6.1g of sodium hydroxide into the beaker in sequence, control the temperature in the beaker to 60°C, add 4.3g of ZSM-5 seed crystals, stir for 0.5h, add 78g of diatomaceous earth, and stir for 1h to obtain a reaction mixture;

[0043] The reaction mixture was put into a reaction kettle, crystallized at 170°C for 24 hours, then filtered, washed, and dried to obtain ZSM-5 zeolite, which was designated as G-2 sample.

[0044] The relative crystallinity of this mesoporous ZSM-5 molecular sieve measured by XRD ray diffraction is 58%, and the XRD spectrogram is similar to Example 1, as figure 1 As shown, the mesoporous volume of the mesoporous ZSM-5 molecular sieve is 0.066cm higher than that of the conventional ZSM-5 molecular sieve 3 g -1 , that is, increased by more than 200%, reaching 0.098cm 3 g -1 . The mesopore vol...

Embodiment 3

[0046] This embodiment provides a kind of mesoporous ZSM-5 molecular sieve, which is prepared by the following steps:

[0047] Add 330g of distilled water and 7.1g of sodium hydroxide to the beaker in turn, control the temperature in the beaker to 60°C, add 4.3g of ZSM-5 seed crystals, stir for 0.5h, add 77g of diatomaceous earth, and stir for 1h to obtain a reaction mixture;

[0048] The reaction mixture was put into a reaction kettle, crystallized at 170°C for 24 hours, then filtered, washed, and dried to obtain ZSM-5 zeolite, which was designated as G-3 sample.

[0049] The relative crystallinity of this mesoporous ZSM-5 molecular sieve measured by XRD ray diffraction is 57%, and the XRD spectrogram is similar to Example 1, as figure 1 As shown, the mesoporous volume of the mesoporous ZSM-5 molecular sieve is 0.047cm higher than that of the conventional ZSM-5 molecular sieve 3 g -1 , which increased by 146%, reaching 0.079cm 3 g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com