Mono-component aqueous epoxy emulsion used for priming paint and preparation method thereof

A water-based epoxy emulsion, one-component technology, applied in the direction of coating, can solve the problems of reducing the performance of the emulsion, troublesome construction process, single large particle size or small particle size, etc., to improve the sealing and permeability. , the effect of improving mechanical properties and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of one-component water-based epoxy emulsion for primer of the present invention may further comprise the steps:

[0030] a: Weigh the raw materials according to the above ratio for later use;

[0031] b: Add epoxy resin monomer and diluent to a four-necked flask with a thermometer, reflux condenser and stirring device at normal temperature and pressure, and keep stirring the mixture for 10-30 minutes;

[0032] c: Raise the temperature of the flask to 70-90°C and keep it warm for 0.5-1.5 hours;

[0033] d: Put the radical polymerization initiator, styrene monomer, butyl acrylate monomer, acrylic acid monomer and methacrylic acid monomer in a mixer, and stir for 10-20 minutes at normal temperature and pressure;

[0034] e: Add the mixture obtained in step d to the flask in step c, dropwise for 1-3 hours, and keep the temperature of the mixture at 70-90°C, keep stirring during the dropping process, and keep warm for 1-2 hours after the dropping is c...

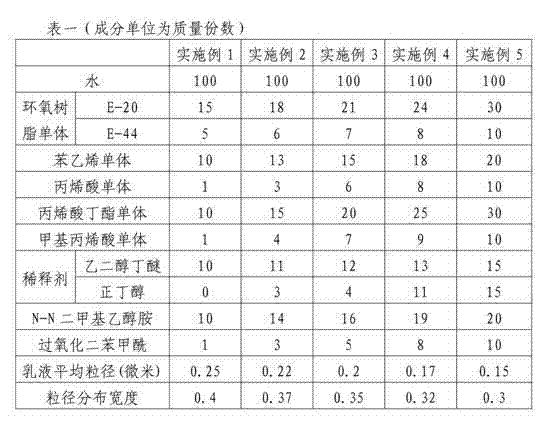

Embodiment 1

[0041] One-component aqueous epoxy emulsion for primer of the present invention comprises water, E-20 epoxy resin, E-44 epoxy resin, styrene monomer, acrylic acid monomer, butyl acrylate monomer, methacrylic acid monomer , ethylene glycol butyl ether, N-N dimethylethanolamine and dibenzoyl peroxide, the contents of the above components are calculated in parts by mass: water: 100 parts; E-20 epoxy resin: 15 parts; E-44 Epoxy resin: 5 parts; Styrene monomer: 10 parts; Acrylic monomer: 1 part; Butyl acrylate monomer: 10 parts; Methacrylic monomer: 1 part; Ethylene glycol butyl ether: 10 parts; N-N Dimethylethanolamine: 10 parts; Dibenzoyl peroxide: 1 part.

[0042] The preparation method of one-component water-based epoxy emulsion for primer of the present invention may further comprise the steps:

[0043] a: Weigh the raw materials according to the above ratio for later use;

[0044] b: Add E-20 epoxy resin, E-44 epoxy resin and ethylene glycol butyl ether into a four-necked f...

Embodiment 2

[0053] One-component aqueous epoxy emulsion for primer of the present invention comprises water, E-20 epoxy resin, E-44 epoxy resin, styrene monomer, acrylic acid monomer, butyl acrylate monomer, methacrylic acid monomer , ethylene glycol butyl ether, n-butanol, N-N dimethylethanolamine and dibenzoyl peroxide, the contents of the above components are calculated in parts by mass: water: 100 parts; E-20 epoxy resin: 18 parts ; E-44 epoxy resin: 6 parts; styrene monomer: 13 parts; acrylic monomer: 3 parts; butyl acrylate monomer: 15 parts; methacrylic acid monomer: 4 parts; 11 parts; n-butanol: 3 parts; N-N dimethylethanolamine: 14 parts; dibenzoyl peroxide: 3 parts.

[0054] The preparation method of one-component water-based epoxy emulsion for primer of the present invention may further comprise the steps:

[0055] a: Weigh the raw materials according to the above ratio for later use;

[0056] b: Add E-20 epoxy resin, E-44 epoxy resin, ethylene glycol butyl ether and n-butano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com