High temperature solder and application thereof

A high-temperature welding and high-temperature technology, applied in welding/cutting media/materials, welding equipment, welding media, etc., can solve the problems of low welding temperature and poor corrosion resistance, improve high temperature resistance and corrosion resistance, and reduce the impact , the effect of reducing residual thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

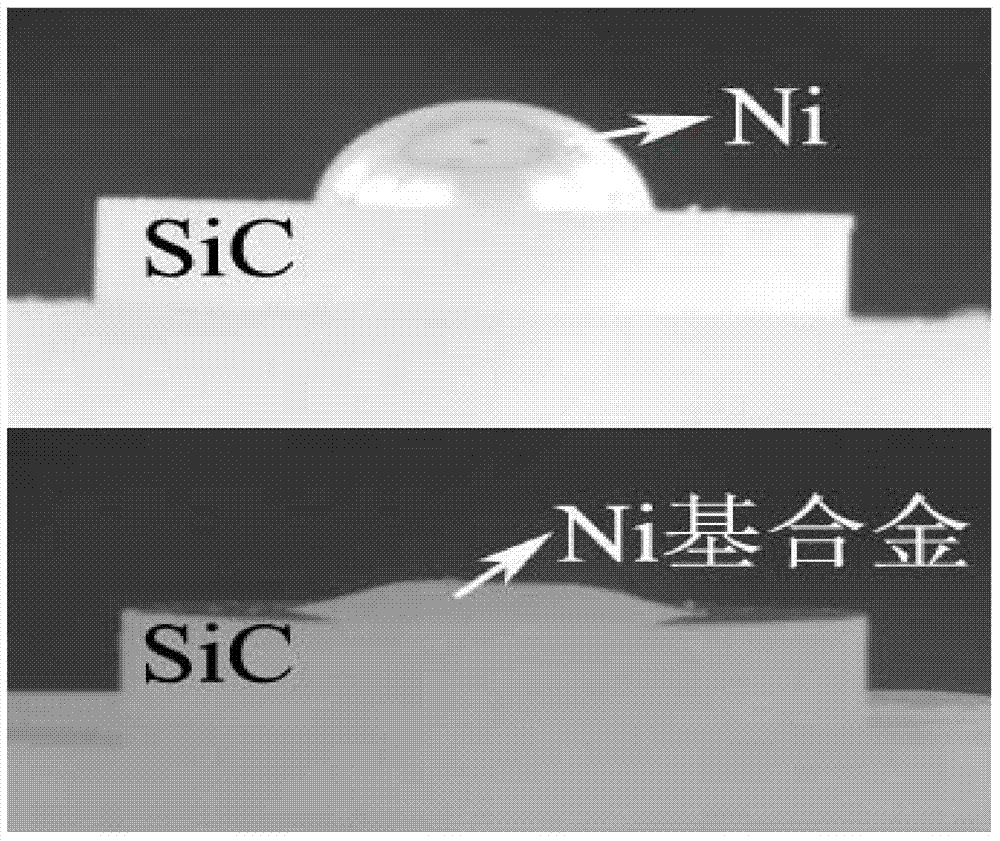

[0025] 1. The nano-scale Ni, Mo, Cr, and Fe powders are made according to 67Ni-30Mo-1Cr-2Fe (that is, the mass percentages of Ni, Mo, Cr, and Fe are 67%, 30%, 1%, 2%, respectively) ) Stoichiometric ratio mixing, adding polyvinyl butyral (PVB), ball milling the mixture in a planetary ball mill for 24 hours to obtain a paste-like solder with uniform composition distribution, which is ready for use;

[0026] 2. The surface to be welded on the silicon carbide ceramic substrate is first polished with 600# water sandpaper, and then placed in acetone and alcohol for ultrasonic cleaning for 15 to 30 minutes, and dried for later use;

[0027] 3. Coat the solder uniformly on the surface to be soldered of the silicon carbide ceramic substrate after the surface cleaning pretreatment, so as to form a ceramic-solder-ceramic three-layer structure, fix it with a fixture, and control the thickness of the middle solder layer to be 10~1000 Between micrometers

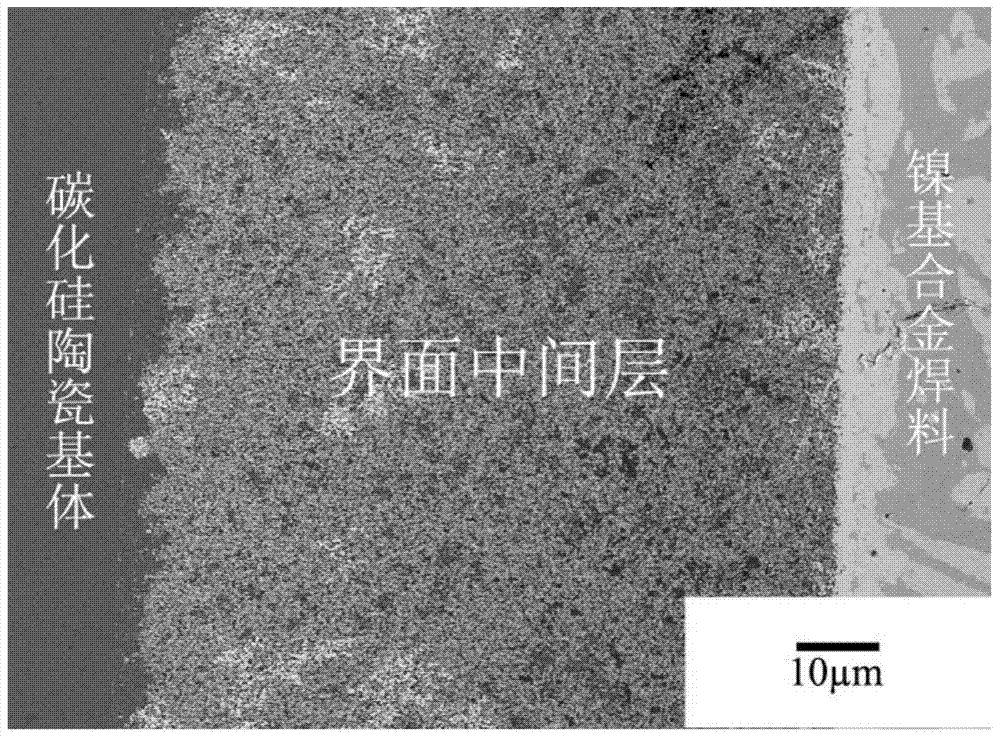

[0028] 4. Put the three-layer structure ...

Embodiment 2

[0031] 1. The nano-scale Ni, Mo, Cr, W, Co, and Fe powders are divided into 57Ni-16Mo-16Cr-4W-2Co-5Fe (that is, the mass percentages of Ni, Mo, Cr, W, Co, and Fe) Mix at stoichiometric ratios of 57%, 16%, 16%, 4%, 2%, 5%), add polyvinyl butyral (PVB), ball mill the mixture in a planetary ball mill for 24 hours to obtain a composition distribution Uniform paste solder, spare;

[0032] 2. The surface to be welded on the silicon carbide ceramic substrate is first polished with 600# water sandpaper, and then placed in acetone and alcohol for ultrasonic cleaning for 15 to 30 minutes, and dried for later use;

[0033] 3. Coat the solder uniformly on the surface to be soldered of the silicon carbide ceramic substrate after the surface cleaning pretreatment, so as to form a ceramic-solder-ceramic three-layer structure, fix it with a fixture, and control the thickness of the middle solder layer to be 10~1000 Between micrometers

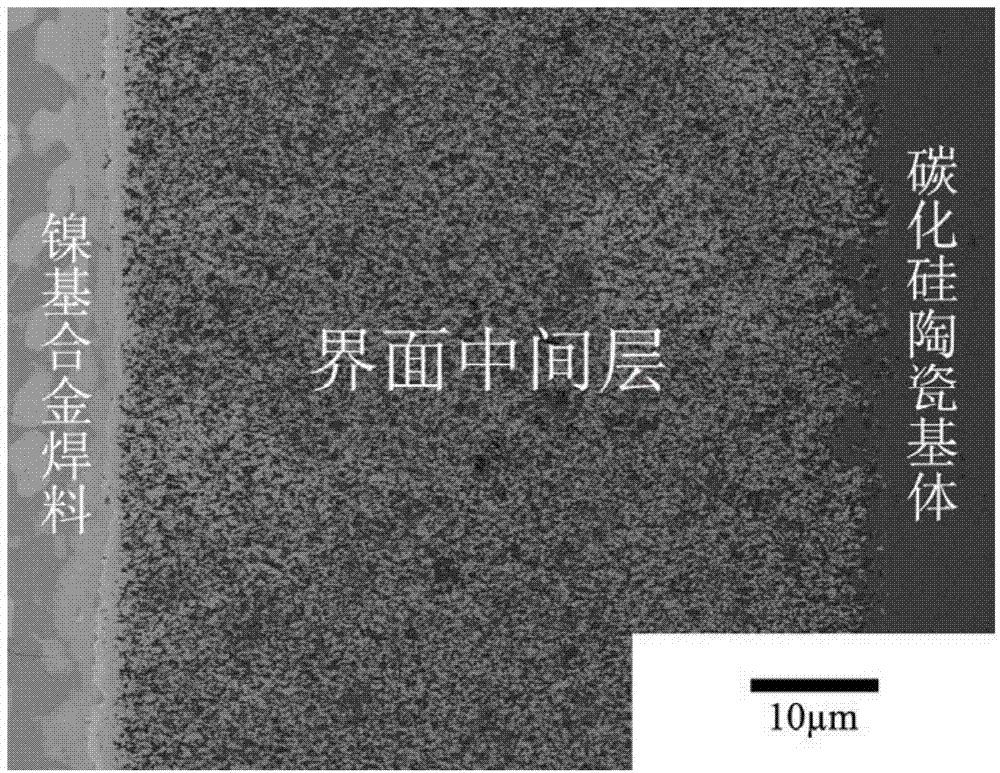

[0034] 4. Put the three-layer structure sample fixed by the a...

Embodiment 3

[0037] 1. The nano-scale Ni, Mo, Cr, W, Co, and Fe powders are divided into 40Ni-15Mo-30Cr-5W-5Co-5Fe (that is, the mass percentages of Ni, Mo, Cr, W, Co, and Fe) Mix at stoichiometric ratios of 40%, 15%, 30%, 5%, 5%, 5%), add polyvinyl butyral (PVB), ball mill the mixture in a planetary ball mill for 24 hours to obtain the composition distribution Uniform paste solder, spare;

[0038] 2. The surface to be welded on the silicon carbide ceramic substrate is first polished with 600# water sandpaper, and then placed in acetone and alcohol for ultrasonic cleaning for 15 to 30 minutes, and dried for later use;

[0039] 3. Coat the solder uniformly on the surface to be soldered of the silicon carbide ceramic substrate after the surface cleaning pretreatment, so as to form a ceramic-solder-ceramic three-layer structure, fix it with a fixture, and control the thickness of the middle solder layer to be 10~1000 Between micrometers

[0040] 4. Put the three-layer structure sample fixed by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com