Novel degradable seedling bowl and manufacturing method thereof

A seedling pot and a new type of technology, applied in the field of rural agricultural waste reuse, can solve the problems of high heating temperature, high production cost, and high crushing requirements, and achieve the effects of improving soil structure, reducing processing costs, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The novel degradable nursery pot provided by the invention is obtained by mixing and sealing crushed plant stalks with livestock and poultry manure biogas slurry, fermenting, compression molding and drying.

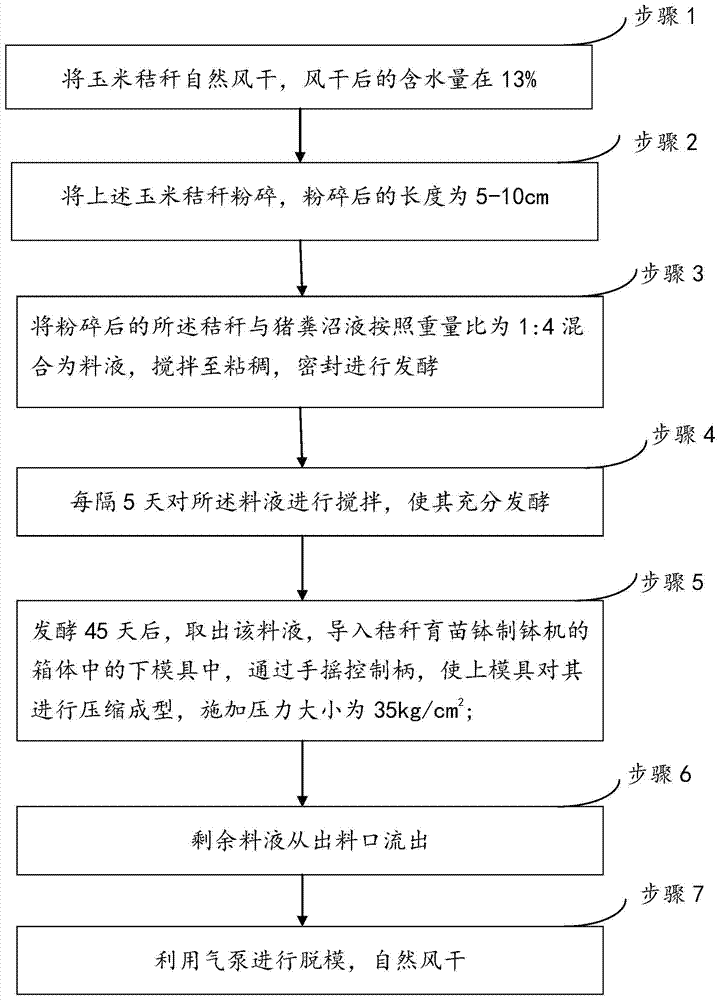

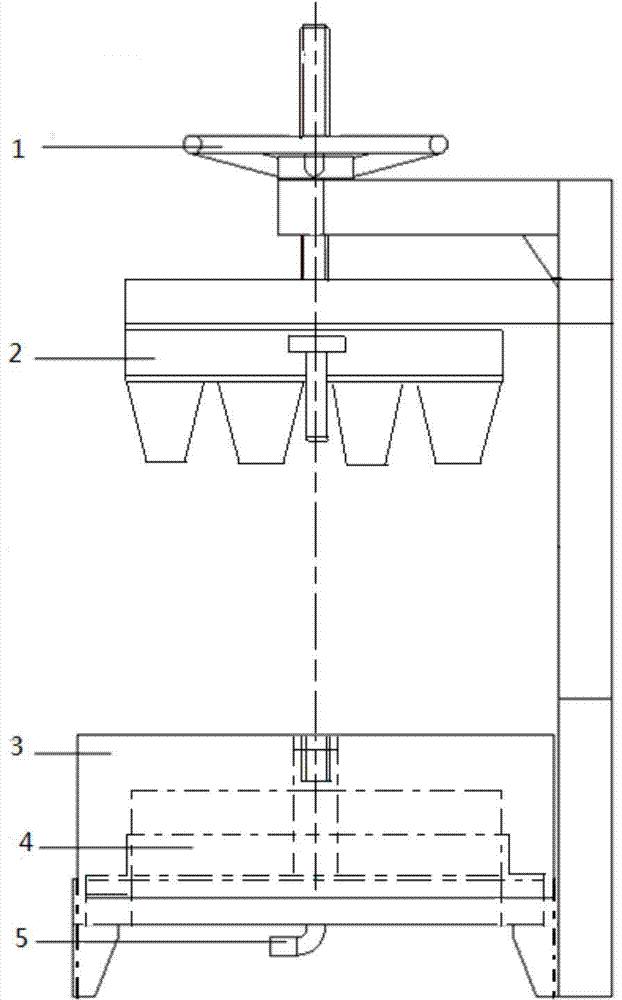

[0028] see figure 1 Shown, it is the preparation method flowchart of novel degradable nursery pot of the present invention, figure 2 It is a schematic diagram of the structure of the straw seedling-raising bowl-making machine in the present invention, and the method adopted in this embodiment is as follows:

[0029] Step 1. Air-dry the corn stalks naturally, and the water content after air-drying is 13%;

[0030] Step 2, crushing the above corn stalks, the length of which is 5-10cm after crushing, and the length of the crushed corn stalks is longer, which not only saves crushing time and labor, but also saves the input cost of crushing;

[0031] Step 3. Mix the pulverized straw and pig manure biogas slurry in a weight ratio of 1:4 to form a feed liquid, stir unt...

Embodiment 2

[0038] see figure 2 , which is a structural schematic diagram of a straw seedling raising pot making machine in the present invention. In order to prepare a novel degradable seedling pot, the method adopted in this embodiment is as follows:

[0039] Step 1. Naturally air-dry the sorghum stalks, and the water content after air-drying is 10%;

[0040] Step 2, crushing the above-mentioned sorghum stalks, the length of the crushed sorghum stalks is 5-10 cm, the length of the crushed sorghum stalks is longer, which not only saves crushing time and labor, but also saves the input cost of crushing;

[0041] Step 3. Mix the pulverized sorghum stalks with cow dung and biogas slurry at a weight ratio of 1:5 to form a feed liquid, stir until viscous, seal and ferment. Here, the present invention uses the weak alkaline environment of the biogas slurry to decompose the sorghum stalks and release a large amount of lignin, thus replacing the chemical binder in the original method for prep...

Embodiment 3

[0048] see figure 2 As shown, it is a structural schematic diagram of the straw seedling raising pot making machine in the present invention. In order to prepare a novel degradable seedling pot, the method adopted in this embodiment is as follows:

[0049] Step 1. Air-dry the corn stalks naturally, and the water content after air-drying is 15%;

[0050] Step 2, crushing the above corn stalks, the length of which is 5-10cm after crushing, and the length of the crushed corn stalks is longer, which not only saves crushing time and labor, but also saves the input cost of crushing;

[0051]Step 3. Mix the pulverized straw and chicken manure biogas slurry into a feed liquid according to the weight ratio of 1:3, stir until viscous, seal and ferment, and use chicken manure to ferment the biogas slurry to replace the original method of preparing seedling pots The chemical binder in the fertilizer reduces the cost and avoids soil pollution. At the same time, it solves the problem tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com