Cigarette filter additive and preparation method and application thereof

A cigarette filter tip and additive technology, which is applied in the application, smoke oil filter, tobacco and other directions, can solve the problems of complex preparation process, unsuitable for large-scale industrial production, and high preparation cost, and achieves a simple preparation process and good industrial practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Disperse 0.2 g of poly(N-2-aminoethylacrylamide-) in 100 mL of aqueous hydrochloric acid and stir at 1000 rpm for 1 hour at 25 °C to obtain a dispersion of polyelectrolyte nanoparticles. Soak coconut shell charcoal for cigarettes in concentrated ammonia water for 2 hours, rinse with deionized water and dry at 105 °C. The dried coconut shell charcoal for cigarettes was impregnated into the dispersion of polyelectrolyte nanoparticles, and stood at 25 °C for 2 h, and the surface was loaded with polyelectrolyte nanoparticles by electrostatic drive in situ growth, filtered and washed. and drying to obtain a filter additive. Wherein, the mass percent content of the polyelectrolyte nanoparticles in the additive is about 0.1%.

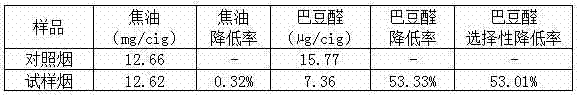

[0025] The above-mentioned additives are applied to cigarette filters, and the added amount in each cigarette filter is about 45 mg. To measure the release of tar and crotonaldehyde in mainstream smoke of cigarettes, and to evaluate the influence of f...

Embodiment 2

[0029] Disperse 0.1 g of poly(N-2-aminoethylmethacrylamide) in 100 mL of aqueous hydrochloric acid and stir at 1500 rpm for 1.5 hours at 30 °C to obtain a dispersion of polyelectrolyte nanoparticles. Soak coconut shell charcoal for cigarettes in concentrated ammonia water for 2 hours, rinse with deionized water and dry at 105 °C. The dried coconut shell charcoal for cigarettes was impregnated into the dispersion of polyelectrolyte nanoparticles, and stood at 30 °C for 3 h, and the surface was loaded with polyelectrolyte nanoparticles by electrostatically driven in-situ growth, filtered and washed. and drying to obtain a filter additive. Wherein, the mass percent content of the polyelectrolyte nanoparticles in the additive is about 0.5%.

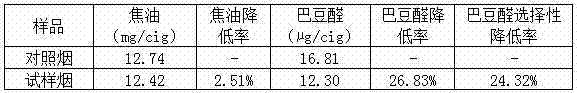

[0030] The above-mentioned additives are applied to cigarette filters, and the added amount in each cigarette filter is about 30 mg. To measure the release of tar and crotonaldehyde in mainstream smoke of cigarettes, and to evaluate the inf...

Embodiment 3

[0034] Disperse 0.5 g of polymethacrylamide in 100 mL of aqueous hydrochloric acid and stir at 2000 rpm for 2 hours at 30 °C to obtain a dispersion of polyelectrolyte nanoparticles. Soak coconut shell charcoal for cigarettes in concentrated ammonia water for 2 hours, rinse with deionized water and dry at 105 °C. The dried coconut shell charcoal for cigarettes was impregnated into the dispersion of polyelectrolyte nanoparticles, and stood at 30 °C for 1 h, and the surface was loaded with polyelectrolyte nanoparticles by electrostatically driven in-situ growth, filtered and washed. and drying to obtain a filter additive. Wherein, the mass percent content of the polyelectrolyte nanoparticles in the additive is about 1%.

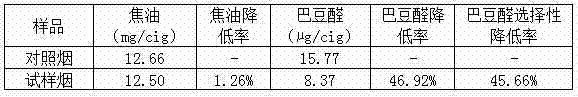

[0035] Apply the above-mentioned additives to cigarette filters, and the added amount in each cigarette filter is about 15 mg. To measure the release of tar and crotonaldehyde in mainstream smoke of cigarettes, and to evaluate the influence of filter tip addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com