Catalyst applicable to synthesis of methanol by multi-component mixed gas as well as preparation method and application of methanol catalyst

A technology for synthesizing methanol and catalysts, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problem of not studying the influence of inert gases on catalytic reactions, etc., and achieve the realization of heat release and heat transfer ability, space-time High yield and the effect of improving methanol selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

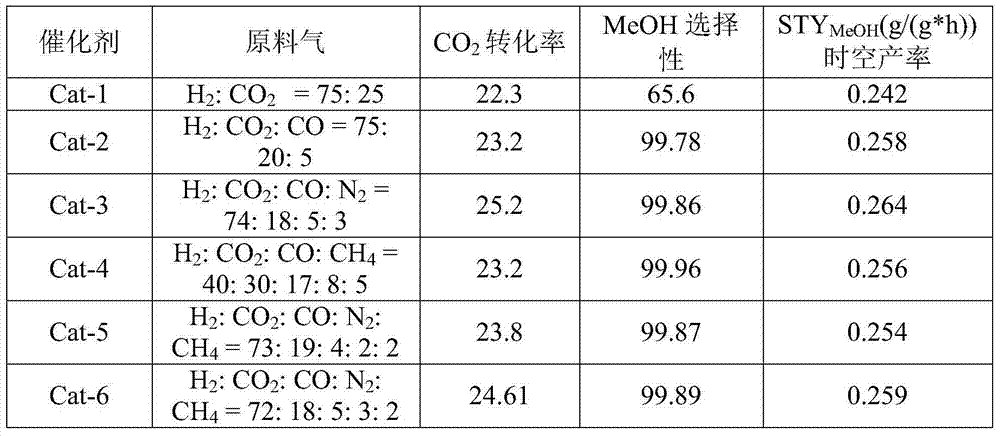

Examples

Embodiment 1

[0035] (1). Synthesize methanol catalyst according to the mass percentage of the following metal oxides: CuO:ZnO:Al 2 o 3 =42%:38%:20%. Weigh 127.64g copper nitrate, 139.56g zinc nitrate, 147.11g aluminum nitrate respectively according to the mass percentage of 42%: 38%: 20%, dissolve copper nitrate, zinc nitrate and aluminum nitrate in 1L deionized water successively, prepare the mixture the first solution.

[0036] (2). Weigh 211.98g of sodium carbonate, dissolve it in deionized water, and prepare a second solution whose molar concentration is 1mol / L.

[0037] (3). Under the condition that the reaction temperature is 20°C and mechanical stirring, the co-current co-precipitation method is used to carry out co-current co-precipitation of the above-mentioned 1L first solution and 1.8L second solution, and the pH value of the precipitate is controlled at 8. Form a co-precipitation suspension. After crystallization at 60 °C for 16 h, the precipitate was washed with deionized ...

Embodiment 2

[0041] (1). Synthesize methanol catalyst according to the mass percentage of the following metal oxides: CuO:ZnO:Al 2 o 3 :La 2 o 3 =44%:38%:16%:2%. Take by weighing 138.19g copper sulfate, 139.56g zinc nitrate, 117.69g aluminum nitrate and 5.32g lanthanum nitrate respectively by the mass percentage of 44%:38%:16%:2%, successively add copper sulfate, zinc nitrate, aluminum nitrate and nitric acid Lanthanum was dissolved in 1 L of deionized water to make up the mixed first solution.

[0042] (2). Weigh 276.38g of potassium carbonate, dissolve it in deionized water, and prepare a second solution whose molar concentration is 1mol / L.

[0043] (3). Under the condition that the reaction temperature is 30°C and mechanically stirred, the above-mentioned 1.7L second solution is added dropwise into 1L of the first solution to precipitate by using the sequential precipitation method, and the pH value of the precipitate is controlled at 8.5, forming a precipitate suspension. After c...

Embodiment 3

[0047] (1). Synthesize methanol catalyst according to the mass percentage of the following metal oxides: CuO:ZnO:Al 2 o 3 :SiO2 2 =38%:40%:20%:2%. Take by weighing 115.48g copper nitrate, 142.00g zinc sulfate, 94.68g aluminum chloride and 6.94g ethyl orthosilicate respectively by the mass percentage of 38%: 40%: 20%: 2%, copper nitrate, zinc sulfate, Aluminum chloride and ethyl orthosilicate were dissolved in 1L of deionized water to prepare the mixed first solution.

[0048] (2). Weigh 211.98g of sodium carbonate, dissolve it in deionized water, and prepare a second solution whose molar concentration is 1mol / L.

[0049] (3). Under the conditions of the reaction temperature being 35°C and mechanical stirring, the above-mentioned 1L of the first solution was added dropwise to the 1.6L of the second solution for precipitation by using the reverse precipitation method, and the pH value of the precipitation was controlled at 9. A precipitated suspension is formed. After cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com