A kind of preparation method of metal oxide nanobelt

A technology of oxides and nanobelts, applied in the direction of chromium oxide/hydrate, titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of high cost, high preparation temperature, complex process, etc., and achieve low cost and low preparation temperature , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Prepare an oxalic acid solution with a concentration of 5%. Weigh 5g of solid oxalic acid with an electronic balance and put it into a small beaker, then measure 95ml of deionized water into the beaker, and stir with a glass rod until the solid disappears.

[0022] Cleaning of monocrystalline silicon wafers: Put the cut monocrystalline silicon wafers into a beaker, add acetone, ultrasonically clean them for 5 minutes, take them out, rinse them with absolute alcohol, and let them dry naturally.

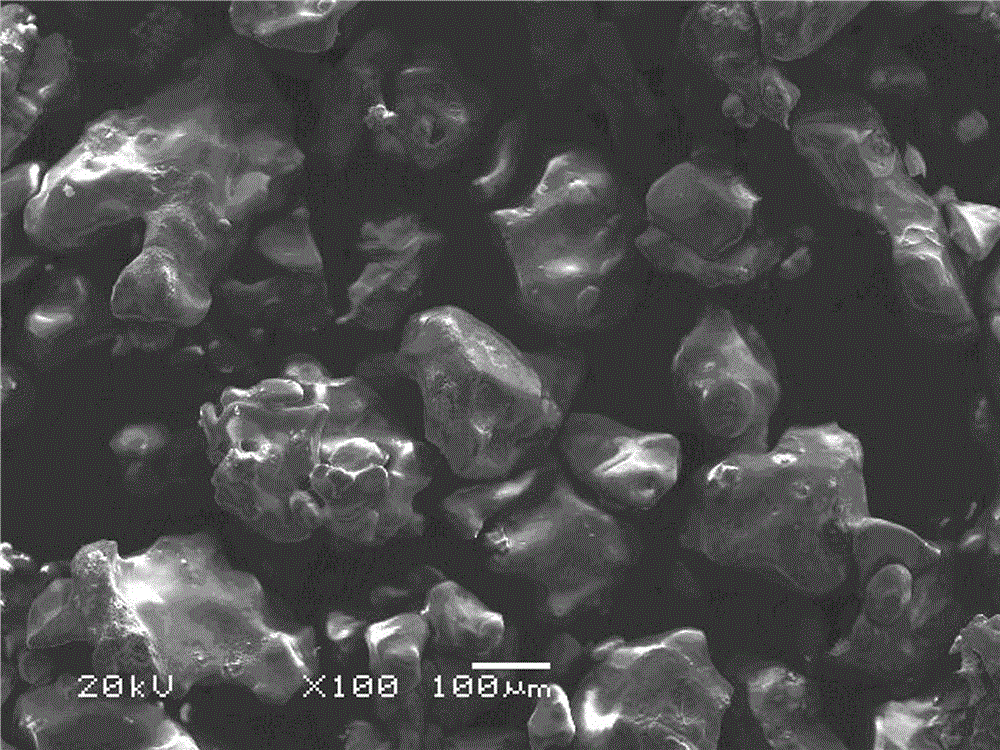

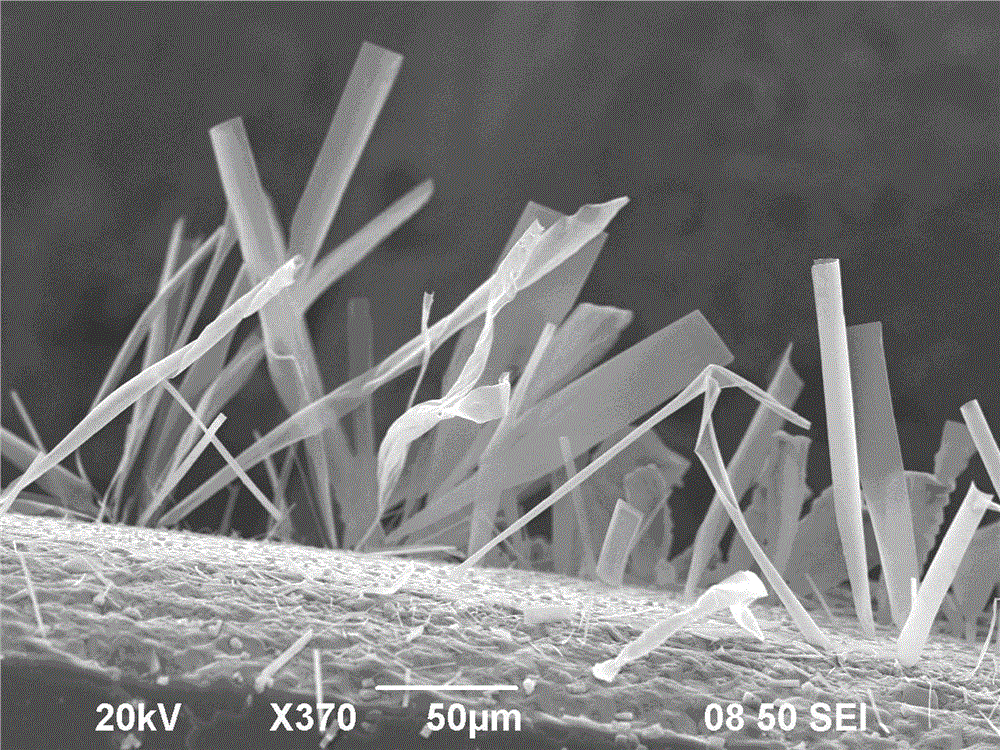

[0023] To grow oxalic acid templates on monocrystalline silicon wafers: take a reaction vessel of appropriate size, pour the prepared oxalic acid solution with a mass concentration of 5%, put the cleaned and dried monocrystalline silicon wafers into the oxalic acid solution, and after 10 minutes Take it out, let it dry naturally, and you can get strips of oxalic acid on the single crystal silicon wafer. Put the oxalic acid powder on the monocrystalline silicon wafer, observe the...

Embodiment 2

[0027] Preparation of oxalic acid solution: use alcohol as a solvent to prepare an alcohol solution of oxalic acid with a concentration of 10%.

[0028] Cleaning the single crystal alumina substrate: Put the cut single crystal alumina sheet into a beaker, add acetone, ultrasonically clean it for 5 minutes, take it out, rinse it with absolute alcohol, and let it dry naturally.

[0029] To grow oxalic acid template on the single crystal alumina substrate: take a reaction vessel of appropriate size, pour the prepared oxalic acid solution with a mass concentration of 10%, put the cleaned and dried single crystal alumina sheet into the oxalic acid solution, 1 Take it out after 1 hour, let it dry naturally, and you can get strip-shaped oxalic acid on the single crystal alumina substrate.

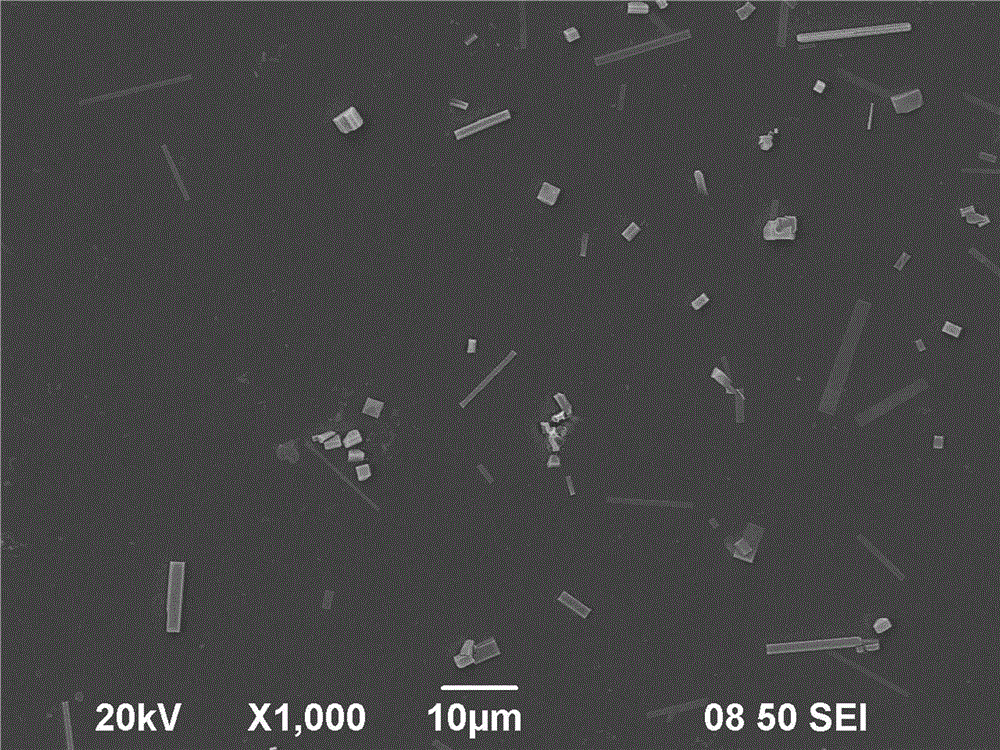

[0030] Zinc coating on the oxalic acid template: the oxalic acid template grown on the single crystal alumina substrate is sprayed with zinc by magnetron sputtering for 60 seconds under vacuum. T...

Embodiment 3

[0033] Preparation of citric acid solution: look up the solubility data of citric acid, and prepare a supersaturated solution of citric acid at room temperature with deionized water.

[0034] Cleaning of monocrystalline silicon wafers: Put the cut monocrystalline silicon wafers into a beaker, add acetone, ultrasonically clean them for 5 minutes, take them out, rinse them with absolute alcohol, and let them dry naturally.

[0035] To grow a citric acid strip template on a single crystal silicon wafer: take a reaction vessel of an appropriate size, pour the prepared citric acid supersaturated solution into it, put the cleaned and dried single crystal silicon wafer into the citric acid supersaturated solution, Take it out after 5 days, let it dry naturally, and you can get strip-shaped citric acid on the monocrystalline silicon wafer.

[0036] Copper coating on the citric acid template grown on the single crystal silicon wafer: Spray the strip-shaped citric acid template grown on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com