Micro-fluidic chip, vinyl-thiol polymeric material for micro-fluidic chip and preparation method

A polymer material, vinyl technology, applied in the modification of internal structure and surface hydrophilic/hydrophobicity, the preparation of microfluidic chip materials, can solve the problems of lack of hydrophilicity and hydrophobicity, material deformation, surface failure, etc., and it is not easy to achieve. The effect of batch processing, easy batch production, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation of embodiment 1 OSTE material

[0047] Take mercapto 70 as an example, where "mercapto" means that the excess material in the composite material is a mercapto-containing material, and "70" means that the proportion exceeding the stoichiometric ratio is 70%.

[0048] Weigh 0.664g pentaerythritol tetramercaptoacetate, 0.300g 1,3,5-triallyl-1,3,5-triazine-2,4,6(1H,3H,5H )-triketone, 0.005g phenyl bis(2,4,6-trimethylbenzoyl) phosphine oxide, mixed with a vortex shaker at a speed of 2500r / min for 40 seconds to make it evenly mixed, and dried in a vacuum Vacuum the dish for 60 seconds to remove air bubbles, pour it into a petri dish with a diameter of 3.5 cm, and then expose it to ultraviolet light with a wavelength of 365 nm for 60 seconds to form a polymer.

Embodiment 2

[0049] Example 2 Directly mixing PEG into the prepolymer for hydrophilic modification

[0050] Take mercapto 70+10% PEG as an example, wherein 10% PEG means that the weight of PEG accounts for 10% of the total weight of the prepolymer mixture (prepolymer and PEG), and the molecular weight of PEG used in the examples herein is 200.

[0051] The pre-preparation is similar to that of Example 1, except that 0.107 g of PEG is added to the prepolymer, and then mixed, vacuumed, and exposed.

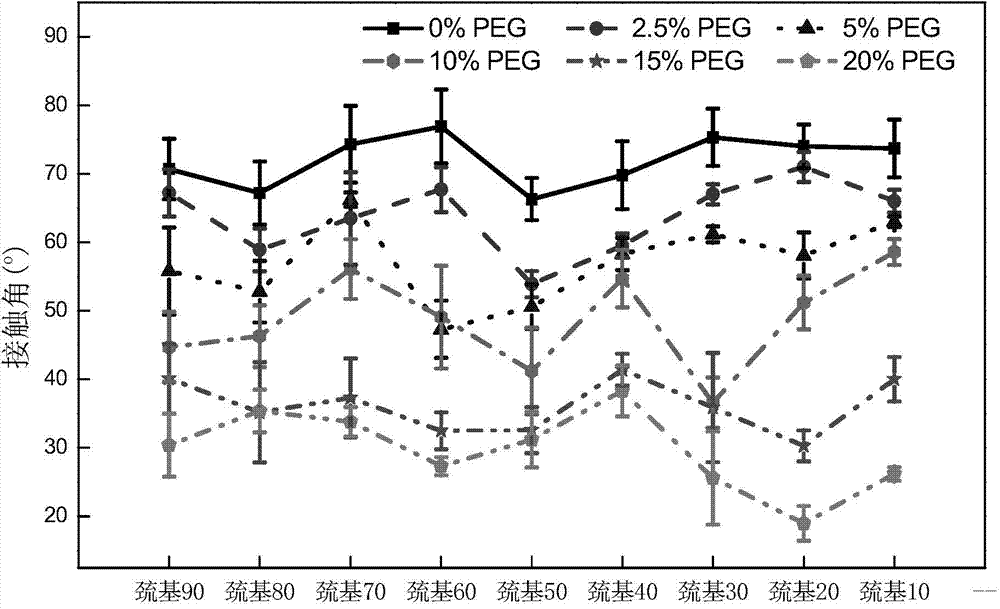

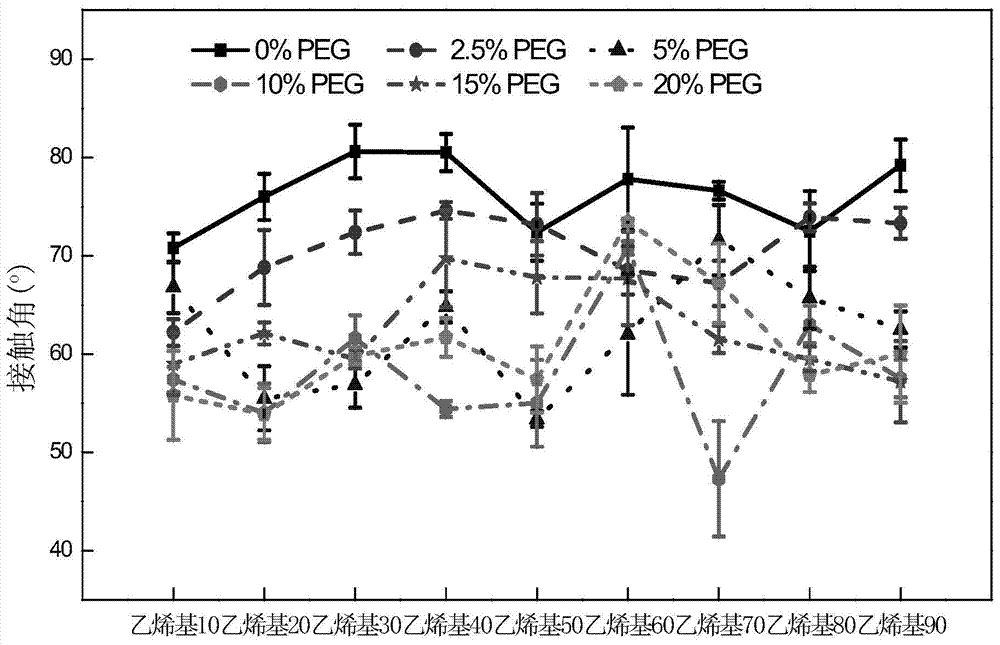

[0052] In the test, it was found that the mixed PEG content is more than 20%, and the material is soft and difficult to tear off; in addition, when the PEG content is high, the transparency will become poor, and when the PEG content is 10%, the transparency and hydrophilicity of the material can be guaranteed. figure 2 Results are given for the effect of PEG content in the prepolymer on the hydrophilicity (contact angle) of the thiol-excess OSTE; image 3 Results are presented for the effect o...

Embodiment 3

[0053] Example 3 Using plasma to treat the surface of the material to further improve the hydrophilicity of the material

[0054] Taking the material prepared in Example 2 as an example, after ultraviolet exposure molding, put it into a plasma surface treatment machine to treat the surface of the material, and the treatment time is 3 minutes. Then put it into a vacuum drying dish and treat it with PEG vapor to evacuate, which can further enhance the hydrophilicity of the surface of the material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com